Bottle Can and Plastic Bottle Inspection

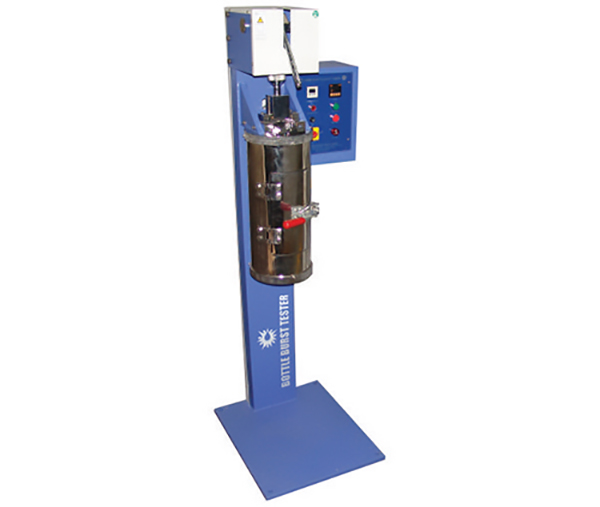

A variety of products and drinks are bottled, and therefore, it is vital to perform the Bottle Can and Plastic Bottle Inspection. Presto testing machine is efficient to test the bursting strength that helps in determining the actual quality of bottles. The low bursting strength is the reason of sudden bursting of bottles due to over pressure or compressor. Testing the bursting strength of the bottles with prior testing procedures is crucial for the production of high-quality bottles or can of high strength.

Presto offers a wide range of testing instruments for polishing the qualities of the products used in the day to day life. The most commonly used products are can and plastic bottles. Therefore, Presto encourages to perform the bottle can and plastic bottle inspection using the appropriate bursting device. Use of proper testing procedures and instruments are essential for the manufacturers of bottles and cans. There are two models of B S tester to check the bursting strength, digital and computerized.

The test is started by allowing highly pressurized air to exerting a high amount of pressure in the sample of a plastic bottle or can. Due to the presence of carbonated drink, the pressurized air simulated the pressure exerted on the bottles. With the help of test, various features such as burst strength, expansion volume, and walls thickness of bottles are determined.

Reviews

Great Work done by Presto team on Bottle Can and Plastic Bottle Inspection Machine.

- Usha Kumari

5

Images

How it Works

Standard

Material

Industry

Test