Other Testing Instruments

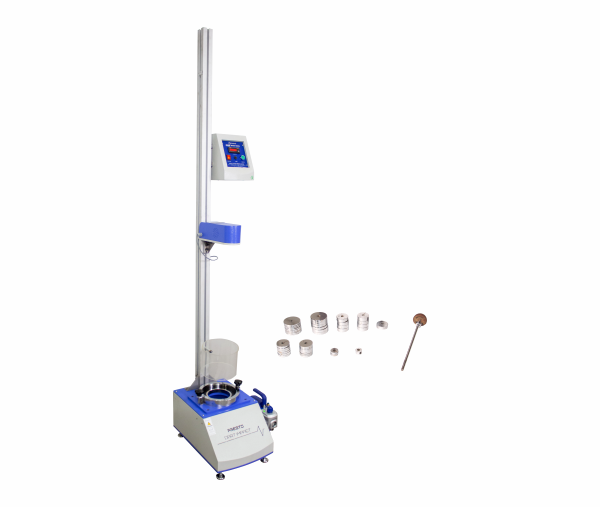

PET Bottle Compression Tester

Presto designs and manufactures the PET Bottle Compression Tester that is used to assess the axial load capacity of the PET bottles. The testing ensures the bottles will not buckle during capping or filling when stacked for storage and shipment. During the testing procedure, keep the specimen on the clamp of the instrument, so bottles held firmly without slipping. For viewing the compression, the required force is set for a given period of time. The instrument is used to determine the maximum compressive forces that can rupture the specimen entirely. The equipment is robust and reliable.

Salt Fog Test Chamber

Presto offers the high quality of Salt Fog Test Chamber manufactured by the team of professionals to ensure the premium quality of raw materials. The instrument is available in various models that can be customized according to the need of the clients. The device is designed according to the applicable standards. The method is reliable to test the corrosion resistance coating when comes under a salt laden environment. The machine is a time tested product precisely designed for evaluation of rust proof ability of components to endure corrosion due to different environmental conditions.

The salt fog test chamber is the most reliable equipment for testing the surface coating for the corrosion resistance. The machine is a time tested product means it can evaluate rust proof ability before time. The device is flexible to replicate the weathering conditions of actual life. The device is double walled provided with glass wall insulation ensuring accurate results. The machine is reliable to fulfill the international standards of testing incorporating all the advanced technology such as air flow meter for controlling the air flow between 0 to 30 psi.

The device has an air jacket heating system that ensures reliability and consistency. The testing procedures are very useful in the laboratories for the quality control purposes. Due to the presence of transparent cover, direct visual observation is possible that optimizes the test observations. The equipment is considered for performing the corrosion test as well as a stress test. The salt fog test chamber conforms ISO, ASTM, JIS, IS and DIN standards.

Salt Fog Chambers

Presto designs and manufactures the Salt Fog Chambers for humidity, water, salt fog, CASS and other testing procedures. The device is easy to operate and provides accurate test results. The machine is flexible to fulfill the need of demanding testing procedures. The machine is strictly designed according to the relevant standard to assess the rust proof ability of components or materials to ensure corrosion caused by environmental conditions. The device is completely tested and checked before delivering to the customers or clients. The chamber is double walled with glass wool insulation available.

The temperate range of the chamber is between ambient to 60 Degree Celsius, which is controlled by a solid state digital programmable temperature controller cum indicator. The indicator has a special zero corrosion PT 100 sensor. There is moisture cum oil filter and air regulator ranging from 0 to 30 psi. Use of FRP (fiber reinforced plastic) ensures the reliable, durable and long lasting components to provide trouble free usage. The machine is adhering to ISO, ASTM, JIS, IS and DIN standards. The salt fog chambers are best used for performing the quality control tests in the laboratory because comparative tests are crucial at laboratories.

There is a transparent cover helpful to optimize the test observations because the see through cover allows direct visual observation of the test samples. The device is a highly significant to perform the stress test and corrosion test based on international test standards that require dry air and automatic water control.

Corrosive Environments Test

The Corrosive Environments Test is performed to ensure the raw materials are of superior quality. The test is performed with the help of appropriate equipment manufactured by Presto and is a good example of the artwork created with the assistance of the team of professionals. The machine is available in three models, and can be customized as per the requirement of the clients or the customers. All the international standards are followed for the testing procedures. This is the reliable equipment for performing the testing procedure to test the coating for corrosion resistance when comes under a salt laden environment.

The equipment for corrosive environments test is the most reliable for testing the corrosive resistance of the surface coating. The testing procedures can evaluate the rust proof ability before time, and the equipment is flexible to replicate the real life weathering conditions. The double walled chamber is provided with glass wall insulation for ensuring precise results. The machine incorporates all the advanced technology including the air flow meter for controlling the air flow between 0 to 30 psi.

The air jacket heating system ensures the reliability and consistency. For performing the quality control laboratory tests, this is very useful testing procedures as laboratory tests require comparative analysis. A see-through cover enables direct visual observation and optimizes the test observations. The testing procedure is used to perform the corrosion test and stress test. The equipment conforms ISO, ASTM, JIS, IS and DIN standards.

Combined Corrosion Testing

Presto manufactures the best quality equipment to perform the Combined Corrosion Testing for consistent and significant corrosion test. A corrosion defense to the original metal is tested on metallic materials finished with a surface coating. This is the quick testing procedure to prevent the corrosive attack and protect the coating surface. The testing procedures help to evaluate the corrosion appearance after a period of time. The duration of the test depends on the corrosion resistance of the coating means the high corrosion resistance material will take longer testing procedures.

The equipment is reliable to ensure the accurate result of corrosion test and is an excellent example of creative work that helps to assess the rust-proof ability of a component under weathering conditions. The combined corrosion testing is used for performing the corrosion test and stress test. These tests are based on the several international test standards requiring water controls and dry air.

Presto designs the double walled chamber fitted with a glass wool insulation for performing test procedures that ensure the accurate results. The methods for corrosion testing are reliable to fulfill the international testing standard. The built-in technology in the chamber includes an air flow meter that regulates air flow between 0 to 30 psi. A reliable and consistent operation is ensured as an air jacket heating system is available. The testing procedures are best for performing the quality control laboratory tests. Chamber is constructed using Fiber Reinforced Plastic (FRP) for reliable and durable components.

Salt Spray Cabinets

Presto offers and manufactures the high quality of Salt Spray Cabinets, which is a reliable machine to test the corrosion resistance of metallic surface coating when exposed to a salt laden condition. The device is time tested and specially designed to check the rust proof capability of the materials. The test is performed to see how a surface coating can withstand corrosion by creating and replicating the real-life environmental conditions. The machine is available in three models for effective measurement of corrosion resistance of a material under salt laden conditions. The touch screen tool is a very helpful feature in the device.

The chamber is double walled (fitted with a glass wool insulation) for ensuring accurate results. The machine is reliable enough to fulfill the international standard of testing. All the advanced technology is used to design the machine including the air flow meter for regulating the air flow between 0 to 30 psi. An air jacket heating system is equipped to ensure reliable and consistent operation. The user can adjust the test temperature between ambient to +45°C. The PLC controlled PID controls the test temperature. The touch screen is considered the most powerful feature in this device because it simplifies the inspection of corrosion resistance for a wide range of sample type.

The touch screen has a special zero corrosion PT 100 sensor and 8 function keys. A 3M flash memory with USB host for USB flash drive. The instrument contributes for performing the tests in quality control laboratories, where comparative testing is crucial. As a see-through cover is available, continuous direct visual observation is possible that optimized the test observation. Presto supplies completely tested salt spray cabinets before providing to the customers or clients with an instruction manual and calibration certificate.

Corrosion Testing Cabinets

Presto offers one of the best and reliable Corrosion Testing Cabinets for testing the metallic materials surface coating for corrosion resistance. The device is time tested and is able to assess the rust proof ability of a material when exposed to different environmental conditions. This is the flexible equipment that can efficiently replicate or simulate the real-life environmental conditions. The instrument is considered the most efficient and reliable for testing the corrosion resistance of surface coating under a salt laden environment and providing the reliable test results. The device has a helpful touch screen tool with integral special zero corrosion PT 100 sensor, 8 function keys, and a 3M flash memory.

Since the corrosion testing cabinets have user-friendly features, users are enabled to adjust the test temperature between ambient to +45°C. A PLC controlled PID is available for temperature control. The touch screen is installed in the chamber for providing the trouble free corrosion inspection. The work area of the device is as per the international standard. There is a solid state digital programmable temperature controller cum indicator for enabling the effective temperature control. Air flow is regulated between 0 to 30 psi with the help of the moisture cum oil filter and air regulator.

An accurate measurement of inlet air pressure is provided with the assistance of the calibrated pressure gauge. For consistent atomizing, a zero choke inert materials atomizers perform atomization. The machine is available in three models where the eco model have a separate user-friendly panel including the following features – a digital preset timer that has memory backup and automatic shut off facility, a pressure gauge, air filter and 60 liters reinforced fiber reservoir, a solid state digital programmable temperature indicator cum controller with an auto cut off facility regulator valve.

Climatic Testing Chambers

Presto Climatic Testing Chambers are the most appropriate tool for corrosion resistance testing of surface coatings. The test is performed to check the rust proof ability of surface coating when exposed to a salt laden environment to withstand corrosion caused by environmental conditions. The device is efficient enough to simulate the real environmental conditions. The user can adjust the testing temperature from ambient to +45°C, which is controlled through a PLC controlled PID. The touch screen tool makes testing procedures simple and trouble-free.

Presto specially designed the climatic testing chambers to perform the quality control laboratory tests, where comparative testing is crucial. A constant direct visual observation of the test item is enabled through the transparent cover contributing to the optimization of testing inspection. The chamber is double wall fitted with a glass wool insulation ensuring correct and reliable test results. The instrument fulfills the requirement of an international standard of testing. The device has air flow meter for regulating the air flow from 0 to 30 Psi. The air jacket heating system is provided that aids in even and reliable operation.

The touch screen tool has built in PT 100 sensor with eight function keys, a 3 M flash memory, and a USB host for USB flash drive. Both stress tests and corrosion tests are performed which are based on several international standards that require automatic water control and dry air. There are some standard accessories like regulator; gauges, cyclic timer, air purging, and time totalizer are provided along with the racks.

Salt Mist Chambers

Presto offers the best quality of Salt Mist Chambers to perform the quality test in laboratories. The device has the ability to replicate the corrosion in the lab and the actual environmental conditions. The machine allows the test samples to be exposed to the appropriate salt spray volume. The machine has a specific touch screen that simplifies the testing operation. The machine has been designed following the relevant standard so that the rust proofed ability of components to endure corrosion, caused by atmospheric conditions, can be easily determined. This is the most reliable equipment for testing the corrosion resistance of metallic materials when exposed to a salt laden environment.

The chamber is constructed using the Fiber Reinforced Plastic (FRP) materials that enable faster corrosion test and replicating significantly corrosive environments, thus provides uniform and reliable test results. The touch screen tool is present with a special zero corrosion PT 100 sensor and the position of the screen is ergonomic that allows the user for convenient operation. Chamber is double walled provided with glass wool insulation.

Salt mist chambers are available in three models, which are equipped with time totalizer, cyclic timers, regulators, air purging and specimen racks and gauges. The product is time tested and an example of artistic work created by the team of experts and skilled professionals. The machine is excellent in simulating the weather or environmental conditions of real life. Due to the user-friendly features, users can adjust the test temperature in the chamber from ambient to +45°C. The temperature is controlled by a PLC controlled PID. This is the best device to determine the corrosion resistant ability of metallic material and its consequence on environmental aspects on the product.

Salt Mist Test Chamber

Presto manufactures the best quality of Salt Mist Test Chamber to perform the consistent and significant corrosion test. The metallic materials finished with a surface coating is tested to provide a corrosion defense to the original metal. This is the faster testing procedure to prevent the coated surfaces from the corrosive attack. The device is time tested, means an evaluation of corrosion appearance after a period of time. The test duration depends on the corrosion resistance of the coating. In case of high corrosion resistance of the samples, the test will take a longer time before rust appearance.

The salt mist test chamber is a reliable machine ensures the accurate result of corrosion test. The machine is an example of a good art product designed to assess the rust-proof ability of a component under different environmental conditions. A very useful equipment for performing the corrosion test and stress test that is based on the several international test standards that require water controls and dry air.

Presto designs the double walled chamber fitted with a glass wool insulation ensuring accurate results and reliable enough to fulfill the international testing standard. The chamber has built-in technology that includes an air flow meter for regulating the air flow between 0 to 30 psi. An air jacket heating system is provided for reliable and consistent operation. The machine has an efficient use for performing laboratory tests of quality control. Use of Fibre Reinforced Plastic (FRP) for chamber ensures reliable and durable components for an extended period of time without any error.

Salt Mist Cabinets

The machine is used to test the corrosion resistance of surface coating under a salt laden environment. The device is time tested for assessment of rust proof ability of materials and is completely flexible in replicating the actual environmental conditions. The double walled chamber is filled with glass wool insulation for providing the correct results and is reliable enough to fulfill the international testing standard.

The salt mist cabinets are designed as per the latest technology that includes an air flow meter for regulating air flow between 0 to 20 psi an air jacket heating system is equipped for reliable and consistent operation. The chamber allows the user to adjust the test temperature from ambient to +45°C. A PLC controlled PID is used for temperature control. The device has a powerful touch screen tool for easy resistance inspection which has a built in PT 100 sensor. There are 8 function keys, a 3M flash memory is available plus a USB host is also provided for USB flash drive.

The machine is efficient for performing the quality control tests in laboratories, where comparative testing is performed. There is a transparent cover to provide the continuous direct visual observation of the test samples and optimizes test observations. Presto supplies the chamber with an instruction manual and calibration certificate adhering to ISO, ASTM, JIS, IS and DIN standards.

Rust Testing Chamber

Presto designs and manufactures the Rust Testing Chamber for testing the corrosion resistance of surface coatings. The test is performed to determine the consequence when exposed to a salt laden environment. The test determines the rust proof ability of a component to resist corrosion caused by environmental conditions. The machine efficiently replicates the real environmental conditions. The user-friendly features allow the user to adjust the testing temperature from ambient to +45°C. There is a PLC controlled PID to control the temperature of the chamber. The touch screen tool in the machine is helpful that simplifies the testing procedures.

The rust testing chamber is specially designed to perform the quality control tests in laboratories as comparative testing is essential in labs. A transparent cover provides constant direct visual observation of the test item, and this helps in optimization of testing inspection. The double wall chamber is fitted with a glass wool insulation that ensures the correct and reliable test results complying with the international standard of testing. The air flow meter incorporated to regulate the air flow from 0 to 30 Psi and an air jacket heating system is also equipped for even and reliable operation.

The touch screen is considered a useful tool with built in PT 100 sensor. There are eight function keys, a 3 M flash memory, and for a USB flash drive, a USB host is also provided. The testing procedure is highly efficient for both stress tests and corrosion tests. These tests are based on several international standards that require automatic water control and dry air. There are some standard accessories like gauges, cyclic timer, air purging, a regulator, and time totalizer are provided along with the racks.

Environmental Testing Chambers

Environmental Testing Chambers are the best reliable machine manufactured and designed by Presto to check the corrosion resistance of the surface coating of metallic materials. This instrument can assess the rust proof ability of a material under different environmental conditions and is completely flexible to imitate the real-life environmental conditions. This machine performs the most efficient and reliable testing procedures to detect the corrosion resistance of surface coating when exposed to a salt laden environment. The rust proof ability of a material is effectively tested with reliable results. The touch screen is an important feature and has an integral special zero corrosion PT 100 sensor with 8 function keys, a 3M flash memory.

The user-friendly features in environmental testing chambers allow users to adjust the test temperature from ambient to +45°C, which is controlled by a PLC controlled PID. The touch screen installed in the chamber provides a simple testing procedure for corrosion analysis. The work area of the machine inside is as per the international standard. There is a solid state digital programmable temperature controller cum indicator for temperature control. An air flow is regulated between 0-30 psi within the chamber with the help of moisture cum oil filter and air regulator.

For accurate measurement of inlet air pressure, a calibrated pressure gauge is available. For consistent atomizing, a zero choke inert materials atomizers perform atomization. The device is available in three models; the eco-model has separate user-friendly panel including following accessories – a digital preset timer that has memory backup and automatic shut off facility, air filter and 60 liters reinforced fiber reservoir, a pressure gauge, regulator valve, solid state digital programmable temperature indicator cum controller with an auto cut off facility.

Salt Spray Testing Chamber

Corrosion Testing Chamber?

Presto manufactures and designs the Corrosion Testing Chamber for testing the corrosion resistance of the metallic materials finished with a surface coating. The machine helps to perform the significant and consistent corrosion test. The equipment is time tested and helps in evaluating the corrosion resistance after a period of time. The duration of the test depends on the corrosion resistance of the metallic surface coating. The test will take longer than the normal time before rust appearance if the testing sample has high corrosion resistance. This is the quick and easy procedure to protect coated surface from the corrosive attack.

Presto corrosion testing chamber is capable of performing consistent and significant corrosion test and are reliable to ensure test results. The very useful equipment to perform the stress test and corrosion test, based on the international standards requiring dry air and water controls. This is an example of a good art product intended to evaluate the rust-proof ability of coated surface when exposed to different environmental conditions.

The chamber is double walled fitted with a glass wool insulation that ensures accurate results. The machine is reliable fulfilling the need for all international testing standards. The chamber has an air flow meter that regulates air flow between 0 to 30 psi. Reliable and consistent operation are ensured with the air jacket heating system. The machine is appropriate for performing the quality control laboratory tests. Fiber Reinforced Plastic (FRP) is used for chamber construction that ensures the reliable and durable components for an extended period of time without any kind of error.

Climatic Test Chamber?

The Climatic Test Chamber is used to determine the corrosion resistant property of metallic materials by replicating the different environmental conditions. The test is performed on the raw material at the initial stage to produce the high-quality goods. The machine is fitted with an effective touch screw having a special zero corrosion sensor. The machine assures safety due to the ergonomic position of the touch screen. This the most reliable and popular testing procedure that provides quick, low-cost and reasonably repeatable features. The machine is used to predict the corrosion resistance of a coating and to maintain the coating process as well.

Presto offers and designs the climatic test chamber to enable quick comparison between actual and expected corrosion resistance. The device predicts the corrosion resistance of the materials and is useful for corrosion test and stress test. The machine can assess the rust proof ability of components or metallic materials to withstand the corrosion caused by environmental conditions. The chamber has user-friendly features that allow the user to adjust the test temperature from ambient to +45°C. A PLC controlled PID is provided to control the temperature. The touch screen feature is powerful for easy inspection of corrosion resistance. The touch screen has a build in PT 100 sensor.

The machine is completely tested and provided with an instruction manual and calibration certificate adhering ISO, ASTM, JIS, IS and DIN standards. The device is available as Korrox –III, CASS and Eco model with customized specifications. The instrument is easy to understand and simple to operate.

Compound Corrosion Testing

Presto manufactures the best quality equipment to perform the consistent and major Compound Corrosion Testing. This test procedure is applicable for metallic materials finished with a surface coating so that a corrosion defense to the original metal can be provided. This is the faster testing procedure that prevents coated surfaces from the erosion. The equipment for performing the test procedure is time tested and can evaluate the corrosion appearance after a period of time. If test samples have high corrosion resistance, then the test will take a longer time before rust appearance, thus, the duration of the test depends on the corrosion resistance of the coating surface.

The equipment used for performing the compound corrosion testing is reliable to provide the accurate result of corrosion test. A good example of art product designed with the efforts of the professional team. The equipment allows assessment of the rust-proof ability of a component when exposed to different environmental conditions. The corrosion test and stress test are performed based on the several international test standards that require water controls and dry air.

The double wall chamber fitted with glass wool insulation for providing the precise results. The instrument is consistent enough to meet the international standard of testing. The chamber has an air flow meter that regulates air flow between 0 to 30 psi. The device has an air jacket heating system for ensuring a reliable and consistent operation. The machine is best used for quality control laboratory tests. Fiber Reinforced Plastic (FRP) is used for the construction of chamber that ensures reliable and durable components for an extended period of time in an accurate way.

Salt Fog Cabinets

The Salt Fog Cabinets are one of the best reliable machine manufactured by Presto to check the corrosion resistance of metallic materials surface coating. This is the time tested machine that can assess the rust proof ability of a material under different environmental conditions. The machine is completely flexible to replicate the real-life environmental conditions. This is the most efficient and reliable equipment to test the corrosion resistance of surface coating when comes in a salt laden environment. The rust proof ability of a material is effectively tested with reliable results. The touch screen has integral special zero corrosion PT 100 sensor and has 8 function keys, a 3M flash memory.

Salt fog cabinets has user-friendly features that allow users to adjust the test temperature from ambient to +45°C. The temperature is controlled by a PLC controlled PID. The touch screen installed in the chamber is capable of easing the corrosion analysis. The inside of machine has a work area as per the international standard, and a solid state digital programmable temperature controller cum indicator provides the temperature control. A moisture cum oil filter is provided to regulate the air flow within the chamber. An air regulator with a range between 0-30 psi is also provided.

A calibrated pressure gauge is available for accurate measurement of inlet air pressure. A zero choke inert materials atomizers perform atomization for performing consistent atomizing. There is a separate user-friendly panel in an eco model of the machine which includes a solid state digital programmable temperature indicator cum controller with an auto cut off facility, a digital preset timer that has memory backup and automatic shut off facility, a pressure gauge, regulator valve, air filter and 60 liter reinforced fiber reservoir.

Determining the Coefficient of Friction

Presto COF Tester is the best and premium quality of coefficient of friction tester which is used in determining the coefficient of friction of the plastic films, laminated papers, etc. The instrument is designed on the rigid metallic base plate. The device is finished with blue and autumn grey combination which is plated with bright chrome plating that offers corrosion resistant finish. The testing instrument is designed as per ASTM D1894, D883, D 618 standards. It comes complete with a calibration certificate which is perceptible to NABL labs.

To Know more about information visit- CO-Efficient of Friction Tester

Coefficient of Frictional Force

Presto’s Coefficient of friction tester is designed to measure the coefficient of frictional force of the plastic films, pipes, sheets and papers. The aboratory test device is designed in accordance with the standards ASTM D 618, D883 and D 1894 standards. The device is used to measure the kinetic and static friction of the test specimens when it slides over itself or other substances under some standard conditions. It is important to determine the coefficient of frictional studies to evaluate the stacking ability of the plastic films and sheets. These studies enable the manufacturers in plastic industries to prevent fatal accidents due to frictional forces faced by the material at the time of transportation, loading, and packaging.

The coefficient of frictional force testing helps to determine the degree of abuse a plastic film will successfully endure, without damaging the contents. The Presto Co-efficient of friction tester measures the coefficient of slipping friction. It is easy to use and portable testing device which is designed ergonomically to test the friction that occurs between the two surface that are laminated with thermoplastic materials such as polyethylene, plastic films, etc.

These additives have different degrees of compatibility with the film matrix. It is a well-known fact that the samples usually exude or bloom to the surface hence lubricates it and makes the material more slippery. Since blooming is not uniform on all areas of the film surface, the results of all the tests are not reproducible. The frictional properties of the plastic films and sheets depend on the uniformity of the rate of motion between two surfaces.

Co-Efficient of Friction of Paper

Finding the coefficient of friction of Paper is an important factor in the packaging industries that helps to measure the quality of packaging product. The digital cum computerized model of coefficient of friction tester is a convenient and easy way that helps to find the property of plastic packaging materials. With the help of this testing machine, it becomes easy to measure the actual behavior of the packaging materials at the time of storage and transportation. Presto Stantest offers two types of Coefficient of Friction of Paper such as Dynamic Model and Digital and Computerized Model.

The instrument is built on rigid and heavy metallic base plate. It is painted with blue and autumn gray color painting and plated with bright chrome plating that makes the device rust proof. The instrument is designed in compliance with the standards ASTM D 618, D883, D1894 ,TAPPI 815 and TAPPI T549 . The device is provided complete with the electrical wiring diagram, instruction manual and calibration certificate which is perceptible to NABL approved laboratories.

It is a very useful testing device which is used by the manufacturers in the plastic industry to avoid any type of accidents because of constraints at the time of loading and unloading due to an excess of friction. The major cause of the increase in the friction is the development of the uneven thickness of sheets that causes unequal distribution of the strength of the sheets. The tester is provided either with digital panel only or with a computerized screen to access the results in digital as well as computerized format both.

Measuring Coefficient of Static Friction

Measuring Coefficient of Static Friction is a major factor that defines the role in manufacturing various products such as paper sheets, pipes, and thermoplastic films. The coefficient of friction tester is used in many industries to measure the coefficient of friction of different products. This is used to measure the static and kinetic friction which is offered by the products to different surfaces in order to maintain the stacking ability of the plastic films, and related products can be determined. Presto offers two models for measuring the coefficient of static friction i.e. Deluxe Model and Computerized cum Digital Model.

Presto offers premium quality of Coefficient of Friction Tester that helps in measuring coefficient of static friction to evaluate the stacking ability of the plastic films and laminated papers. This type of testing enables the manufacturers in the plastic industry to prevent accidents due to friction in the loading, packaging, and transporting materials. The uneven thickness of films could result in increased friction which leads to uneven film strength. This testing methodology reveals the degree of mistreatment the plastic material can tolerate successfully without damaging the quality of the material which is packed inside. This test method helps the manufacturers to prevent accidents that occur due to the slippage or friction in the loading, packaging, and transporting materials. The lab testing machine is easy to operate and offers highly accurate test results.

Calculating Coefficient of Friction

Presto Stantest manufactures premium quality of COF tester for calculating the coefficient of friction of the plastics films, papers, thermoplastics, polyethylene, etc. The laboratory testing device is widely used in the paper and packaging products manufacturing industries. The instrument is designed in accordance with various standard test methods that are provided by different national and international standardization authorities such as ASTM, ISO, BIS, etc. The test is performed to evaluate the stacking ability of the plastic films and sheets. This type of testing enables the manufacturers in plastic industries to prevent accidents due to friction in loading, packaging and transporting the materials from one place to another. The uneven film thickness of can results in the enhanced friction which can lead to uneven strength of the film.

Calculating Coefficient of friction using presto’s COF tester helps to reveal the degree of mistreatment that the plastic films can endure without damaging the actual content. Presto’s Coefficient of friction tester measures the coefficient of sliding friction. It is a simple and precise testing machine which is designed to test the friction that actually exists between the two surfaces that are covered by the same plastic material. In some plastic films, such as polyethylene many slip properties are generated just because of the additives. The additives have a different degree of compatibility with the film matrix. It is a well-known fact that makes the specimen bloom, lubricate it and make it more slippery. As the blooming is not uniform on all the areas of the film, the results that are generated from these tests will not be reproducible. The frictional properties of the plastic films and sheets may be reliant on the consistency of the rate of motion amongst the two surfaces. The results that are obtained from this test procedure are extremely sensitive to the working life of the film or sheet.

Coefficient of Friction Tester for Packaging

Presto Stantest offers premium quality of Coefficient of Friction Tester for packaging testing. The device is used to determine the coefficient of friction of plastic sheets, laminates, films, papers, and pipes, etc. The testing machine helps to measure the kinetic and static coefficient of friction of the materials when it slides over the material itself or on the other substance under some specific conditions. The coefficient of friction testing is necessary to determine the stacking ability of the plastic films and sheets. This testing strategy helps the manufacturers of plastic industries to prevent accidents due to friction in transporting, loading and packing of the materials.

The Presto’s Co-efficient of Friction Tester for packaging works on the basis of standard test method ASTM D-1894 and other related standard test methods. Presto Stantest designs two models of Coefficient of Friction Tester for packaging testing i.e. Digital Model and Computerized model. Co-efficient of friction reveals the degree of abuse that a plastic film successfully endures without damaging the content. The Presto coefficient of friction tester measures the coefficient of sliding friction. It is a simple to use testing device which is designed to measure the friction that exists between two surfaces that are covered with the same kind of material. In some plastic films such as polyethylene and plastics, the properties of slip are generated due to the additives.

The frictional properties of the plastic films and sheets are dependent on the evenness of the rate of motion between two surfaces. The data which is obtained by these testing devices are extremely sensitive to the stage of the film and the condition of the surface.

Section Weight Analysis

Presto is a leading supplier of Hot Wire Bottle Cutter and offers premium quality of machines to test the quality of PET bottles. The instrument is uniquely designed to simplify the task of the bottle cutting and to make the production procedure more responsive and productive. It maintains the precision and repeatability which is mandatory for accurate section weight analysis. The testing machine is designed with an adjustable bottle holder which is designed to hold all shapes of bottles and does not requires to change any tool or part of the instrument to perform the test. Also, the adjustable supports of the device firmly hold the bottle in a distinct manner during the cutting procedure.

Presto Stantest manufactures and supplies the best quality of PET bottle cutter to cut the PET bottles firmly in equal and appropriate sections for section weight analysis. The instrument is equipped with the digital heat controls that help to maintain the level of heat which is required to cut the PET bottles of capacities 200ml to 2000ml with the maximum diameter of 110mm. The wire section cutter accurately cuts the specimen in three parts i.e. Top, Bottom, and Cylinder, Each part of the bottle is cut and helps to calculate the actual weight that helps to match the quality of the bottle to obtain unique wall thickness distribution. This test procedure helps to fulfill the testing requirements to measure the mechanical and physical properties of the bottles. The result of this process is judged on the basis of the statistical results by measuring the weight of each part of the bottle individually.

Section Weight Cutter

Presto’s Section Weight Cutter is easy to use and cost effective method that helps to cut the plastic containers for section weight analysis. The instrument is designed with the heating wires to slice the section of the bottles easily and firmly. The testing machine offers proper cutting of the bottles without deforming its actual shape and size. The offered cutter is manufactured under the guidance of highly skilled and experienced engineers using premium quality of materials. The device is used to cut the bottle in various pieces as per the application requirement.

The device is used to cut the bottle of maximum 2000ml. It comprises of 2 wires that firmly cut the bottle in three sections. The instrument also has adjustable supports to hold the bottles perfectly during cutting. In PET bottle manufacturing industries, there is a significant requirement of section weight analysis of PET bottles to assure the quality of the products. The Hot Wire Bottle Cutter is the best way to conduct the section weight analysis of bottles. The device has a unique design that makes the process of bottle cutting extremely simple which makes the testing procedure easy and simpler. The Presto’s Section Weight Cutter offers a high rate of repeatability along with the best accuracy which is mandatory for accurate analysis of test results. The instrument is easy to operate and perfect for section weight analysis of the bottles.

Plastic Bottle Cutter

Presto Stantest offers the best quality of Plastic Bottle Cutter. The laboratory testing machine is manufactured uniquely for fine cutting of the bottles and to make the production procedure productive and responsive. Hence, it maintains the repeatability and accuracy of rigorous testing which is essential for better analysis and quality assurance. The testing instrument also has an adjustable bottle holder that firmly holds the bottle of different sizes, shaped and diameters and different capacities without the requirement of various parts and unique tools. The premium quality and adjustable support of the instrument is simply superb. It holds the bottle tightly which ensures perfect cutting of the bottles.

Presto manufactures premium quality of Plastic Bottle Cutter for the manufacturers of PET and Preform manufacturing industries to test the quality of the PET bottles. The instrument is equipped with the excellent quality of digital heat control panel which helps to set an appropriate heat level as per the quality of the bottles to cut the bottles of capacities 200ml to 2 liters and diameter of maximum 110mm. The Plastic Bottle Cutter also known as section weight cutter perfectly cuts the specimens in different sections i.e. Top, Cylinder, and Bottom. Each section is cut appropriately with the instrument. After cutting the bottle, each section of the bottle is weighed using the best quality of Digital Balance that offers highly accurate test results. This result helps to measure the weight of each section individually for section weight analysis and to measure the physical and mechanical properties of the bottles.

Hot Wire PET Bottle Cutter

A PET bottle is the best medium which is used to pack different products such as food items, carbonated drinks and many more. These products are also used for the packaging of the chemicals, consumable products, etc. The size and shape of these bottles are essential to maintaining the safety of the products that are packed inside. To ensure the accuracy of the shape and size of the bottles, section weight analysis is done. To perform the test procedure, Presto offers Hot Wire PET Bottle Cutter. It is the best and premium quality of machine which is used to cut the bottles in multiple sections perfectly and accurately without deforming bottles shape.

Presto’s Hot Wire PET Bottle Cutter is designed to cut the individual section of the PET bottles. The maximum capacity and diameter of the bottles that can be cut with the instrument are 200ml to 2000ml and 110 mm respectively. Each section of the bottle can be cut in proper size and dimension without deforming specimens shape and size with the help of this high-quality of the cutter. The instrument accurately cuts the section and then each section of the specimen is weighed using the digital balance for accurate measurement of the weight of the sections. This helps the manufacturers to control the quality of the production. The device is provided with the digital display and controls. The device is also known as section weight cutter.

Industrial Hot Air Oven

Presto’s Industrial Hot Air Oven is widely used to test the aging, heat deformation, and heat resistance of the materials that are manufactured in paper industry, textile industry, and various fields. The lab testing machine is designed in accordance various standards that are provided by standardization authorities such as international thermal association. The testing machine offers highly accurate and reliable test results. The instrument offers right temperature conditions that are required for accelerated testing of various types of materials like rubbers, plastics, metals, yarn, textiles, and many more.

Presto’s manufactures Industrial Hot Air Oven to sterilize various products such as rubber, plastics, medical tools, etc. The instrument is equipped with digital preset time with the maximum setting up to 999 hours. It also has a chart recorder which has been installed to collect the data easily. The machine is fabricated with the imported PID controller and offers the facility of automatic computer generated data output facility. The temperature range of the device can be set between ambient to 300oC. The testing machine comes complete with the user manual, electrical wiring diagram, and a calibration certificate which is perceptible to NABL approved labs.

Presto’s Industrial Hot Air Oven comprised of a double walled chamber which is fabricated with the S.S. material from inside and with mild steel from online. The wall is duly filled with the glass wool which ensures that the cabinet is insulated in an efficient manner. The temperature range of the instrument can be set anywhere between ambient to 300 degrees. The device provides accurate test results.

Hot Air Ovens with Digital Temperature Controller

Presto’s Hot Air Oven is a highly reliable and time testing device. The exterior portion of the instrument is painted with the blue and autumn gray paint and also plated with intense zinc that makes the instrument corrosion free.

Presto’s Hot Air Ovens with Digital Temperature Controller comprises of the double walled chamber where the inside wall is manufactured with the heavy S.S. material, and outside wall is designed with the M.S. material. The Glass wool in filled inside the two walls which ensures that the chamber is well insulated. The temperature range of the instrument can be set anywhere between ambient to 300-degree celsius with the temperature regulation of +1°C. The device is also provided with the temperature controller cum indicator that helps to set the temperature of the instrument easily and accurately. The T/P action of the instrument ensures that the level of temperature does not exceed the designated level.

The device is provided with the heaters in the ribs at the bottom of the oven cabinet. The device is designed with the air circulation fan and a hot air blower that ensures even distribution of temperature throughout the chamber. A separate control panel is also provided on the right side of the instrument that helps to set the temperature accurately for better visual monitoring. The oven is provided with stainless steel trays for appropriate placement of samples.

Hot Air Oven Sterilizer

Presto manufactures Hot Air Oven Sterilizer, which is used to measure the effect of elevated temperatures on various types of materials such as textiles, rubbers, metal, yarn, paper and many more. Hence, it is widely recommended to measure the aging, heat deformation, heat resistance of the products that are manufactured in rubber industries, paper and packaging industries, the pharmaceutical industry, etc. Presto’s Hot Air Oven is a time tested and a reliable testing machine that helps to sterilize the medical tools, instruments, rubbers, plastics, efficiently. The device is designed in accordance with various standard test methods that are provided by different standardization authorities such as ASTM, ISO, BIS and many more. The testing machine is painted with blue and gray color paint and finished with intense zinc or bright chrome plating that ensures corrosion resistance finish of the instrument.

Presto’s Hot Air Oven Sterilizer comprises of the double walled chamber which is fabricated with the stainless steel material from inside and the outer portion is coated with mild steel. The impartial mineral glass wool is incorporated into the walls to make sure that the chamber is well insulated. The temperature range of the device can be set anywhere between ambient to 250 Degree Celsius. With the temperature regulation of +1°C. The instrument is provided with the digital PID temperature controller that offers highly accurate results.

The device is also installed with the high-quality of the heater inside the ribs on the bottom of the instrument inside the oven cabinet. It also has an air circulation fan and hot air blower to measure even temperature distribution. The primary port with adjustable openings has been provided in the oven for change of air and to introduce external sensor. Two adjustable steel trays are provided for appropriate sample placement and storage.

High Temperature Industrial Ovens Manufacturer

Presto, one of the renowned High-Temperature Industrial Ovens Manufacturer, offers the best quality of laboratory hot air ovens which is widely used in rubber industries, pharmaceutical industries, biomedical industries, plastic industries, to sterilize the products. The device is designed in accordance with the standard test methods and guidelines that are provided by various standardization authorities such as International thermal association, ASTM, ISO, etc. The testing device offers highly accurate and reliable test results. The instrument is designed with the double walled cabinet which is insulated with the glass wool.

Presto Stantest High-Temperature Industrial Ovens Manufacturer offers premium quality of Hot Air Oven. The instrument is designed with a double-walled chamber where the inside wall is designed with the stainless steel material, and the outside wall is designed with the mild steel.The instrument is duly filled with the glass wool which ensures that the chamber is well insulated. The temperature range of the device can be set anywhere between ambient to 300 degree Celsius. The instrument also has digital temperature controller cum indicator which is installed to achieve the best level of accuracy.

The device is also provided with the ribs in the bottom of the cabinet. The testing device is incorporated with the air circulation fan and a hot air blower that ensure even temperature distribution. The major port is provided inside the cabinet that helps to make changes in the level of air. The control panel is also provided on the right side of the body, that aid better monitoring of test results.

Yarn Tensile Testing Machine

Presto Yarn Tensile Testing Machine is used to evaluate the tensile strength of single or doubling yarn with peak value. This helps to determine the breaking force, toughness, and elongation of yarn. The machine accurately determines the stress characteristics with a constant rate of extension. The tool is helpful and beneficial for the yarn industries, besides PET and packaging, textile industries, rubber and plastic industries.

Yarn tensile testing machine comprises of the upper jaw and lower jaw where yarn testing sample is placed. The lower jaw moves at the designated speed with the help of the standard motor, which is installed using a CE standard electrical wires. The motor stresses the lower jaw. The upper jaw does not move and remains stationary. The machine is designed with heavy mild steel ensuring significant stability and providing the high-quality testing results with over travel and overload protection.

The device is based on the principal of constant rate of transverse (CRT) and is widely used for measuring the tensile strength of materials. The machine ensures the accuracy in determining the tensile strength of yarn and provides a safe and reliable operation. The instrument is supplied with two sets of grips and provides a grip to grip separation between 25 to 700 mm. This is the best-suited device to check the tensile strength and elongation of yarn.

Wire Rope Tensile Testing Machine

Presto offers a wide range of instruments, one more reliable and high quality of Wire Rope Tensile Testing Machine is provided to test the tensile strength of wire rope. The strength of wire rope matters for most of the manufacturing industries because the low strength and easily breakable wire rope could be troublesome and distract the quality of the products. This is the highly advanced tensile tester with all the modern apparatus and features.

The wire rope tensile testing machine is required for the tensile testing of strands and wire rope. The test is performed to determine the breaking force, elasticity, elongation and yield strength of the wire rope. The test helps to determine the tensile strength of the wire ropes in an efficient way. The equipment has a modular structure for safe and reliable testing procedures.

The instrument is equipped with a servo motor that runs at variable speed and is supplied with two sets of grips. The grip to grip separation is ranging between 25mm to 700mm. The graphic user interface PC is connected that provides the accurate speed control during the testing operation. The Windows-based tensile software is available that is efficient to store basic tensile and compression test readings. This is the most reliable machine to test the tensile strength of a product in an efficient way.

Plastic Tensile Testing Machine

The tensile strength of plastic materials means the maximum strength in which it deforms or breaks. The equipment operates on the principle of CRT that is a constant rate of the transverse. The device assists in analyzing the behavior of the material when subjected to a tensile load. Various efficient testing machines guarantee the accurate results, but, it is already proved that no one can beat the quality and accuracy for testing the tensile strength of plastic material better than Plastic Tensile Testing Machine manufactured by Presto.

The instrument is comprised of upper clamp and lower clamps. The upper jaw remains stationary and lower jaw is moved with the help of a motor. The testing sample of plastic is placed between the upper and lower clamps and only lower jaw moves at the designated speed. The machine provides the exact cross head speed between 50 to 500 mm per minute. A universal S type and pancake type load cell is added with +0.5% accuracy.

Presto supplies the machine with a calibration certificate which is traceable to NPL approved labs. The machine is able to perform automatic load sensor sensing through advance electronics. The auto stop facility is provided for the overload or travel safety that is controlled through the special software. The plastic tensile testing machine is designed with the hard, mild steel that assures stability.

Elastomers Tensile Testing Machine

Elastomers show the elastic properties. However, the rubber and elastomer used interchangeably. Presto offers the reliable Elastomers Tensile Testing Machine to evaluate the tensile strength of elastomers. Elastomers are dynamic materials due to its elasticity and resilience properties and are required for a wide range of industries. The key property of elastomers is to deform and recover from stress, and tensile testing helps to detect these critical properties of elastomers.

With the help of elastomer tensile testing machine, the tensile strength of the elastomers can be determined effectively, means the ability to deform and then recover automatically due to high tensile strength. If the products made of elastomers are not able to recover once deform means the low-quality material is used without testing the tensile strength. The machine has a modular structure that enables a reliable and safe operation.

The equipment provides a grip to grip separation ranging from 25mm to 700mm, and there are two sets of grips supplied with the device. A servo motor is equipped that is efficient to run at variable speed. Accurate speed control is provided with a graphic user interface PC. Presto supplied the machines with a calibration certificate that is perceptible to NPL approved labs. Basic tensile and compression test readings are stored in Windows based tensile software program.

Cable Tensile Testing Machine

Presto is a manufacturer, supplier and exporter of Cable Tensile Testing Machine that is highly demanded by the wire and cable industries due to the high tensile strength, optimal performance, stress-free operation, durability and reasonable price. The instruments complied with all the national and international norms and tested from various parameters to provide the accurate result.

The cable tensile testing machine is appropriate for testing the tensile strength optical cable and optical fiber. The device is supplied with two sets of grips and offers a grip to grip separation between 25 to 700mm to avert damage to the sample during testing. The device has a precise cross head speed from 50 to 500mm, and a Servo Motor runs at a variable speed which is intended for power supply. The accurate result is ensured with the graphic user interface PC and a Universal S type, or pancake type load cell is connected that have an accuracy of +0.5%.

The machine has total advanced design and features fitted with an over load or travel safety device. Presto supplies the standard device with a calibration certificate traceable to NPL approved labs. The machine is able to perform the automatic load sensor sensing through the advanced electronics. The user-friendly features made the machine more popular among the different manufacturers of cable.

Tensile Strength Tester for Adhesive Tapes,

The Tensile Strength Tester for Adhesive Tapes is one of the best product to determine the actual adhesive strength of the tapes. The adhesiveness is crucial for the proper packaging of a material. The machine is based on the constant rate of transverse (CRT) principle and is equipped with the lower jaw and upper jaw. The device is effective to test the tensile strength of adhesive tape as well as various materials such as plastic, metal, ferrous alloys, steel, and aluminum. There are different models available for the instrument such as digital model, digital cum computerized (eco) wintest model, and Zeus ultimo. The digital model is upgraded as Zeus ultimo, which is used to perform several laboratory testing purposes.

Presto offers and manufactures the high quality of tensile strength tester for adhesive tapes that is incorporated with the upper jaw and lower jaw, where lower jaw is moveable and upper jaw is stationary. The sample of adhesive tape is placed between the jaws, and a motor is provided to move the lower jaw. The machine has a gear box and lead screw arrangement with the special sensor connected to load cell. The special sensor helps to determine the load exerted on the upper jaw. The digital display is provided to show the result, which is measured in kilograms.

The CE standard electrical wiring and standard branded motor are incorporated in machine made of heavy mild steel. The device ensures the trouble-free maintenance and convenient operation. The micro-switches and the main switch are also supplied with the device for safe and steady operation. The machine is meant for providing protection against overload.

Tensile Strength Tester for Plastic Films

Presto manufactures the high-quality Tensile Strength Tester for Plastic Films that is used to evaluate the tensile strength of plastic materials used for plastic films. The device efficiently determines the actual tensile strength of plastic materials and helps in the manufacturing of the high-quality plastic products. The machine is based on the principle of CRT (Constant Rate of Transverse), and is equipped with two jaws; upper jaw and lower jaw. The machine is built using heavy mild steel that makes it highly stable.

The tensile strength tester for plastic films is of high quality means it provides several safety features like over travel protection and overload protection. The sample or specimen of plastic is placed between the upper jaw and lower jaw. A standard motor helps to move lower jaw at the designated speed. Movement of lower jaw evaluates the actual tensile strength of the material or specimen. The upper jaw does not move.

A gear box and lead screw arrangement are equipped. The device has a unique sensor efficient to judge the load exertion on the upper jaw and indicates the reading in kilograms, which is the digital format. The special sensor is connected with a load cell. For durability and stability, special case hardened lead screws are provided. The machine has a modular construction that ensures smooth operation.

Laboratory Tensile Testing Machine?

The Laboratory Tensile Testing Machine is used to perform the tensile test as per the need of the industry provisions. Tensile testing provides information about the yield strength and material ductility. The device is useful to read the physical and chemical properties or mechanical behavior of various material such as metals, iron, plastics, ceramics, composites, and, therefore, recommended for performing the laboratory tests.

Presto offers the reliable and efficient laboratory tensile testing machine? based on the CRT (constant rate of reverse) principle. Use of heavy mild steel ensures the stability and provides high quality results. The machine is available as digital model, eco model and fully computerized Zeus ultimo model. The intellectual technology based components used in the device that allows accurate evaluation of tensile strength.

The lab machine has two clamps called as upper jaw and lower jaw (or clamps). While testing the strength of different materials, only lower jaw moves at a designated speed with the help of a standard motor whereas the upper jaw remains stationary. The CE electrical wires are used to install the motor, which creates the stress in the lower jaw. The tensile test measures the ability of a material to withstand forces that tend to pull it apart or deform. This helps to determine the exact amount or value of the material stretches before the complete failure. The machine provides safe and reliable operation considering the ease of the end users.

Color Viewing Light Booth

Presto offers the high quality and reliable Color Viewing Light Booth to maintain the color consistency and quality. The visual assessment of color is performed under different lights such as CWF light, D65, ultraviolet black light, TFL light, etc. The instrument is recommended for the textiles and yarn, plastic, paper, paint and plating industries and many more. The gray scale assists for the color change inspection. This is the highly recommended machine to test the color consistency and quality of fabric, paint, etc.

Presto offers the Euro Model, USA Model, Asia Model, which are efficient to analyze the color of a material in a specified light and diminishes the access of external lights so that sample color can be tested accurately. The Color Viewing Light Booth is equipped with an accurate light cabinet that contributes in marking the difference by evaluating the garments, textiles, clothes, fabrics, leather, etc.

The machine is equipped with five standard lights such as artificial daylight (D 65), tungsten filament (TFL light), TL – 84 light, UVB (ultraviolet) light and CWF (cool white fluorescent light). The sample of a fabric or other material looks different under different light conditions. This is the best-suited machine for a garment manufacturer, fabric dying, and yarn. The common problem of metamerism, wherein the color of the sample appears to match under one light source but seem dissimilar when observed under another light source. Presto cabinet is beneficial to solve the issue of metamerism.

Color Testing Cabinet

Presto manufactures and offers the Color Testing Cabinet in Asia Model, USA Model and EURO Model to test the color consistency issues in textiles, fabrics, garment, cloth, leathers and so on. The instrument helps to identify the accurate color of fabrics as color appears different under different light conditions. The device is beneficial for solving the Metamerism issue, a common color issue faced by the industries where color plays the primary role.

The phenomenon of metamerism, where the color appears different under different light sources, can be testing effectively with the help of color testing cabinet. The device allows simple procedures to match the colored products or materials under different lights and conditions. The various light sources equipped contributes to detecting the common problem faced by the paint and plating, and textile industries. The different models are based on the conditions and environments related to the specific country. For example, the Asia model is perfect to use according to Asian environment and industries. Same is applicable for USA and EURO models.

The cabinet has different light sources such as D – 65 – Artificial daylight, TFL Light-Tungsten Filament, TL – 84 Light, UVB Light-Ultra Violet, CWF Light-Cool white fluorescent, etc., and the cumulative usage is recorded in hour meter, which is imported from Germany. Presto provides the efficient machine with dust cover, 45-degree viewing stand, and calibration certification. The device is capable of measuring the color consistency of the products under different light sources.

Color Matching Box

The Color Matching Box is an efficient instrument of Presto to detect the phenomenon of Metamerism and test the color consistency issues. The machine is available in Asia, USA, and EURO model to deal with problems of the specific country with a specific environment. The device is widely accepted by the significant number of industries such as plastics, textile industries, paint and plating and so on. The instrument enables to test the color of a material in specified light sources to decrease the intrusion of external lights.

The equipment provides a wide viewing area equipped with diverse light sources to detect the phenomenon of metamerism. The different light sources are representing the commonly found lighting conditions, for example, according to the Asian conditions in Asia Model. The color matching box ensures simple detection of products that display even performance under different lighting conditions.

The instrument is equipped with different light sources such as TFL light, CWF light, Ultra Violet black light, D65, etc. The machine is widely used by the manufacturers of yarn, fabric processors and suppliers, and garment manufacturer. With the help of a gray scale, the investigation of color change is performed. The cabinet is vastly used by a large number of industries such as paint and plating, plastics, textile industries because the color is an important factor of quality for these industries. The instrument provides the convenient way to match colors in different light conditions under different time.

Color Matching Booth

Presto offers the best, highly reliable Color Matching Booth maintaining the color consistency. The different color appearance of fabrics or other material under different light sources causes the problem of color inconsistency. The actual color required cannot be located easily due to the different appearance of the same color sample. The machine is highly effective for the industries such as textile industries, manufacturers of garments and exporters, where the color of fabrics plays a significant role.

The equipment has wide viewing area to test the sample under multiple light sources. It is easy to detect the phenomenon of Metamerism, in which color of the same product appears different under different light sources. The sample of fabrics has to test under various light sources, for example, artificial daylight, TFL light, TL, Ultra Violet light, CWF light, etc. Testing under different light sources helps to judge the exact color difference. A mismatch sample could be easily detected, and a right sample that does not change under all lights could be recovered. The gray scale contributes for color change inspection,

Presto offers color matching booth, available in Asia Model, Euro Model, and USA Model, suitable for color tests. These models are useful to operate for specific conditions as per the specific need and environments of a country. For example, the Asia Model allow test according to the Asian environment. This is the highly reliable machine used by all production companies and industrial laboratories.

Visual Color Matching Cabinets

The color appears different under different lighting conditions such as artificial light and natural lights. The manufacturer of garments has the primary issue to check the color consistency of fabric so its original color appears same under different lights. Presto offers the best, reliable and high quality of visual color matching cabinets to solve the issue of color consistency. This is the best-used machine for garment manufacturer and exporters, yarn, and fabric dyeing industries.

The visual color matching cabinet performs a visual assessment of color under standard lights such as TFL light, CWF light, Ultra Violet black light, D65, etc. The multiple light sources are equipped with a wide viewing area that allows to locate the Metamerism issue (sample appears to match under one light but appear different under another light). The sample material has to go through several lights to get the final approval.

By testing under different types of light sources enable to judge the accurate color difference. When the match of samples does not change under all lights, it means the color quality of the sample is as per the requirement. The machine is significantly used by the paint and plating, plastic and textile industries because the color quality is crucial for such sectors. The color change analysis is performed with the contribution of grey scale. Presto offers Asia Model, Euro Model and USA Model suitable for color tests.

Non-Destructive Testing Machine

It is a user-friendly and easy to use a device that offers simple operation and used to measure the thickness of all ferrous and non-ferrous material such as PET bottles, Prefoms, aluminum tanks, glass bottles, Water tanks, etc. Precise and accurate test results can be determined with the device easily.

Magna-Mike 8600 is a premium quality of non-destructive testing machine that works on the principle of Hall Effect technology. To calculate the thickness of the bottles, the instrument requires both sides of the container. The target ball is placed inside the bottle, and the magnetic fragment is placed on the outer surface. The probe’s sensor which is present in the magnetic fragment quickly senses the distance between the ball and sensor and the results are displayed on the screen. The instrument is used to test the thickness of plastic bottles that are used in the packaging of medical and pharmaceutical products, scientific glasses and glass containers, aluminum beverage cans, foam, paper glasses and other HDPE containers.

The Magna-mike 8600 is the best and non-destructive method that tests the thickness of the bottles. The testing machine is widely used in PET and Preform Industries to measure the thickness of preforms and bottles in highly effective manner. The machine works on the principle of Hall’s Effect. Presto Stantest, one of the renowned manufacturer, supplier, and exporter of testing machine, supplies best quality of Magna-Mike 8600, a product from Olympus.

Measuring Thickness of Aluminum Beverage Cans

Presto offers the best quality of Magna-Mike 8600. It is the best device which is used by the manufacturers of packaging products for measuring thickness of aluminum beverage cans, PET bottles, preforms, glass containers and many more. The instrument is provided with the target ball, magnetic probe, and a digital display screen. The magnetic probe of the device has probe sensor that accurately measure the thickness of the wall of containers. The testing instrument offers highly accurate test results and displays the results on the screen. The device supports various languages such as English, French, Japanese, Portuguese, Norwegian, Polish, Czech, Italian, Spanish, German, Chinese, Swedish, Dutch, Hungarian and Russian.

Presto Stantest a premium quality of testing instrument i.e. Magna-Mike 8600, a product from Olympus. The device is used for Measuring Thickness of Aluminum Beverage Cans, glass containers, glass bottles, PET bottles, PET containers, preforms, and many more. To operate the device appropriately, first of all, place the target ball inside the bottle or beverage can. This will touch the surface of the bottle from inside. Now place the tip of the magnetic probe on the outer surface of the can in such a manner that the ball and magnetic probe lies opposite to each other. The sensor inside the magnetic probe quickly senses the difference between the ball and probe and displays the result on the screen. The instrument is designed to all user-friendly features that help to operate the device easily. The device is designed with all the standard test methods that are provided by national and international standardization authorities.

Portable Thickness Gauge Testing

Magna-Mike 8600 is a high quality of portable thickness gauge testing tool from Olympus, which is used to measure the thickness of the PET bottles using non-destructive methodology. It is a user-friendly and high-quality of a testing device that performs simple operations that are used to measure the thickness of non-ferrous materials such as glass bottles, plastics cans, preforms, aluminum bottles, PET products, water tanks and many more. The testing device works on the principle of Hall’s Effect Technology. The Magna-Mike 8600 is a portable bottle thickness measurement instrument that works on simple and easy magnetic procedure to perform repeatable measurements of non-ferrous materials.

Measuring the thickness of the walls of the PET bottles is mandatory for the manufacturers in PET industries to ensure the quality of the bottles. This can be tested with the help of Magnamike 8600. It is an ideal test machine that tests the thickness of the bottles easily and efficiently. The instrument is manufactured by Olympus and Presto Stantest is an authorized dealer of the portable thickness gauge testing tool – Magnamike – 8600. Presto offers the laboratory testing machine all across India and in various countries like Nigeria, Bangladesh, Bahrain, Thailand, Zambia, Indonesia, Sri Lanka, and UAE. The machine provides accurate and precise test results. The display screen of the device shows maximum, Minimum and differential values with graphical representation. The instrument can save up to 475,000 data logs, and this data can be transferred to other devices easily via. USB

Thickness of Plastic Bottles

The instrument is ergonomically designed with user-friendly features which make the instrument easy to operate and provide precise and repeatable test results. The device works on the methodology of Hall’s Effect that helps to perform non-destructive testing. The testing machine offers highly accurate and reliable test results. It is equipped with a colored digital screen that provides accurate results of wall thickness.

Magna-Mike 8600 is used to measure the thickness of plastic bottles that are used in packaging industries to pack different products. It is a portable and handy device that works on the simple magnetic method to make repeatable and consistent measurements of non-ferrous materials. The device can be operated easily. Wall thickness measurement of the bottles can be done when its target ball is placed inside the container, and the probe is placed on the outer surface of the device. The hall’s effect sensor of the machine accurately determined the distance between the target ball and magnetic probe. The result of thickness easily displayed on the digital screen.

It is an amazing testing device which is manufactured by Olympus. Presto is an authorized dealer of the instrument and offers the device to the manufacturers in India, Nigeria, Bahrain, Bangladesh, Zambia, Thailand, Sri Lanka, Indonesia, and UAE.

Plastic Bottle Pressure Tester

Presto offers and manufactures the reliable and efficient Plastic Bottle Pressure Tester to test the quality of Plastic bottles. PET and plastic bottles are used widely such as bottling of carbonated drink, fruit drink, and another liquid beverages, thus maintaining the quality of bottles is the responsibility of the manufacturers. For this purpose, burst strength testing of bottles is performed using the appropriate procedures and instrument.

For performing burst test, a significant amount of pressure is exerted in the bottles with the application of highly pressurized air, which simulated the exerted pressure on the bottles when a drink (carbonated) is filled inside. The test contributes to determining expansion volume of bottle and thickness of the wall, besides burst strength. Presto Plastic Bottle Pressure Tester is available as a digital model and computerized model. Both of the models are effective to provide the accurate results.

The machine is supplied with a timer that displays a digital reading. The maximum value is 999 seconds for the timer. An auto cutoff facility is also provided. The buzzer sounds once test procedure is completed. Automatic pressure setting is enabled by HMI touch screen as well as a self-calibration property is also available. The machine is advanced, simple to operate, accurate, and convenient for the end users.

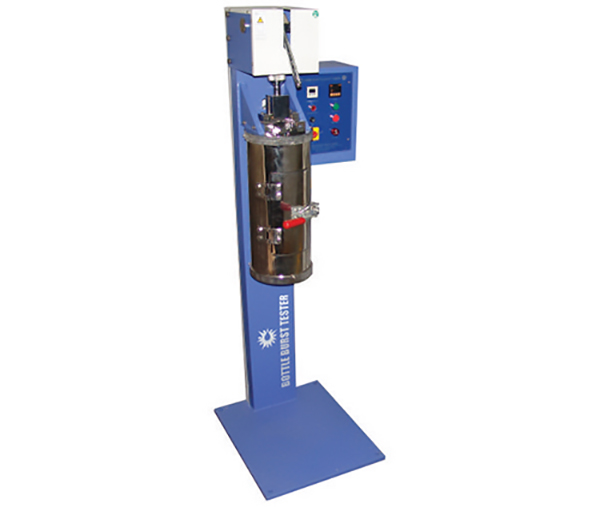

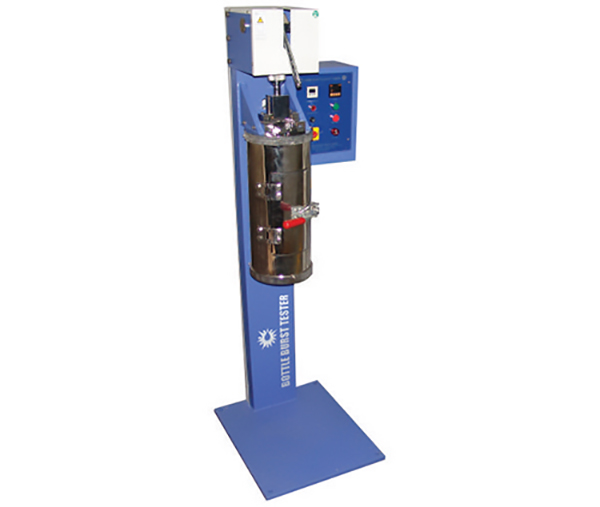

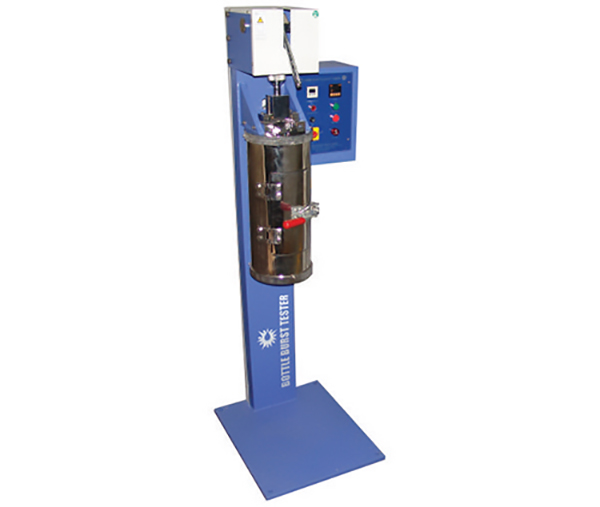

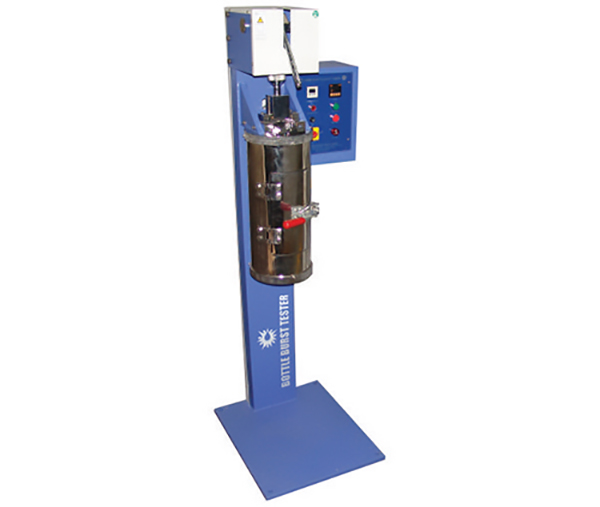

Plastic Bottle Burst Tester

Presto offers the advanced Plastic Bottle Burst Tester to test the bottles that meet minimum pressure capabilities and measures the rate of the volume expansion. The device is useful for both the manufacturing industries and laboratory purposes. The proper quality testing is performed to provide the high quality of plastic bottle manufacturers.

The plastic bottle burst tester provides the high quality of plastic bottles so that bottling industries can supply the safe products to the end users. Sudden bursting is a major problem, and the efficient testing procedure prevents such condition. Testing the quality of the plastic materials is the responsibility of the manufacturers, and therefore, Presto designed the best instrument to solve the quality issues.

While testing, the test sample is placed on the opening of the instrument and a pressurized air is used to fill the sample of the bottle. The test contributes in determining if bottle walls are thick enough to burst or not, therefore the thickness of the wall plays a significant role. The device has a digital timer that can be preset with a maximum limit of 999 seconds. The machine has an auto cut off facility. This method is highly precise and accurate to determine the quality of a bottle.

PET Bottle Pressure Tester