UTM Machines - Digital Cum Computerised Test Model | Presto Group

Tensile Testing Machine Digital Cum Computerised Win Test Model

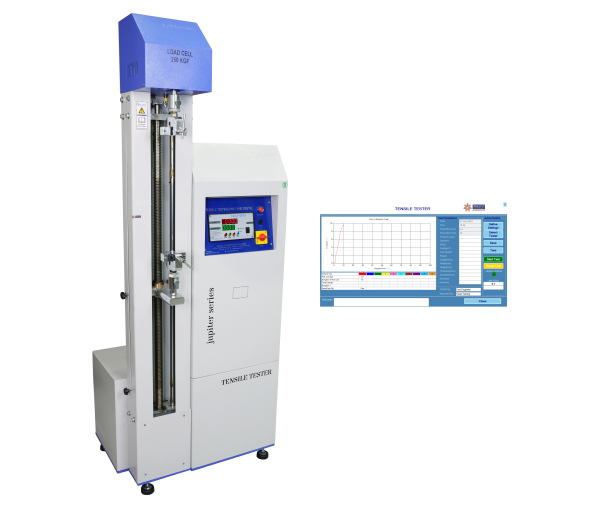

Tensile strength is the stress at which a material breaks or permanently deforms. PRESTO Digital Tensile Tester is a state of the art, highly versatile equipment for checking the breaking strength of packaging related raw materials and finished products. It has a single column vertical movement on low friction ball screws.

This digital cum computerized model of tensile strength tester comes with a digital display and computer display that makes it easy for manufacturers to conduct tensile strength tests on the materials. The machine operates by clamping the material sample in between two grips and then applying a tensile force to the sample until it breaks. The digital control system and Win-Test software measure the amount of force applied, as well as the elongation or deformation of the sample, allowing for the calculation of various mechanical properties.

One of the standout features of this tester is its Graph Test Report, which displays force versus time. This allows users to easily monitor the strength of materials over a period of time, making it easier to identify any weaknesses or defects.

Users can also email reports directly from the tester, as well as tabulate data in Excel for further analysis. Presto is a leading tensile strength tester manufacturer and offers this testing equipment at the best price.

Zeus Ultimo 3.0 tensile testing machine

Presto's newly launched Zeus Ultimo 3.0 tensile testing machine is one of the high-quality lab testing instruments that is used to test the tensile properties of the materials and help manufacturers test the breaking, tensile, and compression strength of various materials, components, and finished products.

This UTM machine has been designed in accordance with various test standards that include ASTM D412, ASTM D429-73, ASTM D624, ATM D638-01, ASTM D76, IS 13360-5-7, IS 3400(Part1-1987).

By using this quality UTM machine one can also evaluate the performance of different sets of materials and ensure that quality products will be delivered to the customers. By conducting tensile strength tests on the products, the manufacturers will ensure the specimen's durability and elongation strength.

PRESTO tensile testing machine computerized model will perform the test in two modes-as a stand-alone (digital control) machine or through computer control with software. This UTM machine comes with reliable and easy-to-operate user-friendly software that can be useful in various industries like rubber, plastics, automotive, polymers, textiles, R&D labs, production, and material testing.

Digital Tensile Testing Machine Cap 2500KG

Dual Lead Screw Based Model ensures stability while testing.

The Presto Tensile testing Machine is based on the Constant Rate of Traverse (CRT) principle. During the test, the sample is held between two jaws. The upper jaw is stationary, while the lower jaw is made to move at a designated fixed speed with the help of a motor.

The motor is fitted with a gear Box and a lead screw arrangement (100mm or 200mm per minute). A sensor, connected with a load cell, senses the load exerted on the stationary jaw and directly indicates the reading in kgs (in digital format). The Presto Tensile testing Machine is fitted with special case hardened lead screws for stability and durability. The machine is equipped with a standard branded motor and CE standard electrical wiring. The completely modular construction of the Presto Tensile Testing Machine ensures trouble free maintainance and easy operation.

The frame of the Presto Tensile testing Machine is fabricated using heavy mild steel in order to ensure that it has the requisite rigidity and strength. The machine incorporates various built in safety arrangements such as over load and over travel protection.

The Presto Tensile testing Machine is finished in Autumn Gray & Blue combination painting. Further the bright chrome / zinc plating has been added to impart a corrosion resistant finish.

The Instrument comes complete with Instruction Manual; Electrical Wiring Diagram & Calibration Certificate traceable to NABL approved Labs.

Tensile Testing Machine with COF (LCD Display)- Model No. TTMC-LCD

Presto comes with a new model of tensile testing machine with a COF tester. This testing machine is well designed with industry standards like ASTM D618, ASTM D 883, BS 2782, and ASTM D 1894. With the help of this testing machine, you can easily measure the tensile strength along with the co-efficient of friction of various products like plastic films, sheets, and rubber and paper.

Presto is a leading tensile strength tester machine manufacturer that will help manufacturers in testing the tensile properties of the materials with ease. It is designed to apply a controlled force to a sample of the material and then measure the response of the material to that force. This type of testing is commonly used in the manufacturing and engineering industries to ensure that materials meet certain performance standards and specifications.

The COF measurement feature of the machine allows for the determination of the frictional resistance between two surfaces in contact with each other. This is an important property to measure for materials used in applications where sliding or rubbing is a quality factor to be considered.

It allows for accurate and reliable testing of material properties, helping to ensure that products are safe, durable, and meet customer expectations.

UTM machine

The universal tensile machine is manufactured precisely to determine the ductility of various materials like rubbers, textiles, metals & plastics by exerting tensile strength in a structured manner. This allows the operator to assess & evaluate a material’s elongation levels and tensile tolerance that is necessary for the durability & ductility of materials.

The UTM machine is offered with a specimen conditioning accessory and highly advanced features that are responsible for the pinpoint accuracy delivered by the lab testing machine.

Universal testing machine

The Universal Tensile Machine (UTM machine) is an advanced material testing system designed to evaluate the mechanical properties of various substances, such as (rubber, plastics, metals, and textiles). By applying controlled tensile force, this tensile testing system measures a material’s elongation, tensile tolerance, and ductility, ensuring durability, reliability, and compliance with ASTM and ISO standards.

How Does a UTM Machine Work?

The UTM test machine functions by securing a test sample between two grips—one fixed and the other movable. The machine applies a gradual tensile load, and as force increases, it records key parameters such as:

- Tensile strength

- Yield strength

- Elongation percentage

- Break point analysis

- Tensile Modulus

This material stress analysis helps manufacturers determine how much force a material can endure before failure.

Applications of a Universal Tensile Machine

The UTM machine is widely used in quality control, R&D, and industrial manufacturing to assess the strength, flexibility, and performance of materials. Key industries benefiting from this load testing machine include:

- Automotive (testing metal and plastic components)

- Aerospace (evaluating aircraft-grade materials)

- Civil Engineering (ensuring construction materials meet strength standards)

- Packaging Industry (analyzing tensile properties of films, foils, and paper)

Why Choose a Presto Stantest UTM Machine for Material Testing?

A universal tensile testing machine helps manufacturers identify material limitations , prevent failures, enhance product reliability. Compliance with global testing standards like ASTM and ISO ensures that products meet safety and durability requirements.

By integrating a UTM test machine into quality control processes, company can ensure their materials perform optimally under real-world conditions.

Presto Group, India’s leading universal tensile machine manufacturer and supplier. Call +91 9210 903 903 for best quality solutions.