Testing Instruments in India

Burst Strength Tester Digital in Mumbai

Burst Strength tester in Mumbai can easily be accessed. For that, you must contact the team at the branch office situated in Andheri West. Presto has designed various versions of Bursting Machine including Digital, Pneumatic, Computerised, etc. The Digital Model is a bestseller and is equipped with the finest quality parts and technologies.

Burst Value is an important factor in the Paper and Packaging Industry. Upon this specific criteria, the quality of the material is decided. The amount of force applied on which the test specimen get burst or completely ruptures is termed as the bursting strength of that sample. To apply the force in this model, it has a manual rotating wheel which pushes the clamp downwards. On the base, there is a sample clamping platform which has grooves on its surface to prevent slippage of the specimen. The operator must note that the sample should be cut in a circular shape before placing it on the testing base.

The grips provided on the test base are designed with standardised features which ensure that the test is not at all disturbed while in progress. This assures that no error must appear in the test results. The force value applied is recorded in digital format on the screen which delivers high accuracy in the values. The machine is very easy and simple to operate and deliver precise results for advanced quality control. The accuracy has been assured with the microprocessor-based digital program installed in the machine.

Salt Spray Chamber in Baddi

Corrosion testing is important for checking both the quality of coating process and the surface material. Corrosion can not only destroy the appearance but can also seep deep inside the material and slow down its processing functions. That is why to protect the material form building corrosion it is important to apply a good quality coating layer which can resist the corrosion process for long and protect the inner material form further damage. Salt Spray Tester by Presto is a highly renowned test chamber in the coating, paint and plating industry. It is designed as per ASTM B 117 and JIS Z 2371. It also follows several other test standards too. Equipped with touchscreen display screen for operation as well as monitoring and new Ethernet connectivity. Salt Spray chamber can be purchased from Baddi and all other locations in India. We also export to overseas locations.

Top Load Tester in Baddi

PET bottle and containers are often placed one over other in storage and in transit position. Especially when the Bottles are kept at this position for a long time. This happens when the PET bottles are either get transported to distant location or stored in warehouses for long time span. The amount of pressure experienced by the bottle at the bottom will make it generate crack or may also rupture to lose the inside content. To avoid such situations, manufacturers must assure that the Bottles must be tolerate to a fixed amount of vertical load. This can be tested with Presto’s Top load testing machine. The machine is equipped with inverted straight plates which exerts vertical compressive force and the load cell attached to it ensure that the force is uniformly distributed. Digital controls deliver test data with complete accuracy and high precision. Interested clients can now have Top Load Tester in Baddi along with other top industrial towns of India.

Tensile Testing Machine in Baddi

Tensile strength is a valuable property factor of plastic film and foils. As per their applications, they are required to be rigid or flexible up to a limit. To see if they are following the industry criteria or not, they must be checked under controlled tensile forces. Tensile strength tester is designed as per international standards and allow the user to check the tensile strength, elongation strength, breaking strength etc. of the material. These values play a major role in deciding the quality standards of the products. The tester is equipped with a tensile fixture having a strong grip at the product. The travel length can be easily specified by using safety limit switches. The digitally operated areas have a bright LED screen for test value display and feather touch buttons to control the fixture movement. Tensile Testing Machine is now available in Baddi and other regions of the entire nation. We also export our products to international nations.

Wall Thickness Gauge - Magna Mike 8600 in Baddi

Measuring wall thickness was earlier a destructive technique in which the layers of a product are cut and teared to precisely measure the thickness of the same. This process being destructive leads to a major loss in products. Compared to this Magnamike 8600 uses a non-destructive thickness measurement process. It has a probe tip and various sizes of target (balls, disc and wire). The measurement is conducted when the hall-effect sensor of probe tip is placed on the external surface of the material and the target on the internal side. When the two meets due to magnetic forces, the distance in between is precisely recorded to be the wall thickness. The gauge can be used for testing glass, plastic, and any non-ferrous material. Ferrous in products can interfere the readings and develop error. Wall thickness Gauge – Magna Mike 8600 can be easily purchased from Baddi and other major location of India. Also we cater in overseas countries fulfilling their testing needs.

Hot Wire Bottle Cutter in Baddi

Hot wire bottle cutting machine is a unique equipment which is used for cutting PET bottle section wise. The bottle sections are further used in quality control test like section weight analysis of PET bottle. In this test method, the three sections of the bottle, which is top, middle and bottom section are precisely sliced and weighed separately. It is said that the separate weight of the product must be as per the industry requirement and if they are not, then there must be a quality flaw and the product can be straight away rejected. Therefore, the machine used for cutting of bottles must allow precise slicing. Hot wire bottle cutting machine is equipped with high grade of Kanthal wire for slicing which assures that the area of sections which are sliced will be precise. Interested clients can place purchase Hot Wire Bottle Cutter from Baddi and other vital industrial towns of India.

Humidity Test Chambers in Baddi

Humidity tester is used by various industries for testing their material or product in programmed conditions of humidity and temperature. It can be used on checking the effects of extreme humid conditions on product for a long time span. The chambers are equipped with German imported Circulation fan inside the chamber for uniform circulation of air. The test conditions are digitally controlled using microprocessor based digital display. The specimen placement area has ample amount of space various sizes of sample. The test conditions can be easily controlled by the operator. The test results are visually inspected after the test is completed. A PID temperature controlled is fitted in the chamber for accurate measure of modifying temperature. Can be used for testing resistance of coated or uncoated materials against natural humid conditions. The Humidity Test Chambers is available in Baddi and in other top most industrial regions across India.

Box Compression Tester in Baddi

The compression forces are often faced by corrugated carton boxes when one package is kept on the other. This happens when the boxes are stored in warehouses or loaded in shipment or in other form of vehicles. Especially when it is the case of storage or long distance transporting, the boxes suffer a lot of vertical load on their surface for a long time period which can lead to rupture of the box at base and may be it gets buckle. This can damage the content inside loosing you the reputation and product quality. Box compression testing machine is designed as per international standards and is equipped with digitally controlled display screen for recording test values. The machine has a strong compression plate equipped with a load cell for uniform distribution of forces. Box Compression Tester is also available in Baddi along with other major locations of India.

Edge Crush Tester in Baddi

Paperboard material has several properties which are must for testing and evaluation as depending upon them the applications are decided and the materials are categorized. Edge Crush strength of paperboards can be tested using Edge Crush testing Machine. The test equipment is a digital model and is entirely based upon a microprocessor program. It can perform all three crush strength test (ECT/RCT/FCT) and evaluate material’s edge strength, ring crush strength and flat crush strength. The fixtures are specially designed for the three distinct test modes. The digital display screen records force values precisely. The machine exerts uniform amount of pressure on the test sample and the point at which the resistance of the sample becomes zero and it starts to crush, it is recorded instantly. The Edge Crush Tester can be availed from Baddi, other industrial towns and across the world.

Bursting Strength Tester in Baddi

Burst strength of material is of huge importance for its application and selection criteria. Industry require a test equipment which can be used for evaluating bursting strength/factor/Index all and deliver highly précised force calculations. Bursting Strength tester by presto is one of a kind test equipment which is available in various versions including analogue, Digital, one with pneumatic pressure control, with test data printing facility and one which can be connected to user computer. Equipped with highly advanced features such as high grade diaphragm which is suitable for repeatable testing, digital Bursting Strength Tester in Baddi recording of test values, equal force distribution, strong specimen clamping fixture and grooved base for zero slippage of the specimen. Bursting Strength tester is now also available in Baddi, which is a renowned Industrial Town. Presto understands the need of quality control and thus deliver services to major locations of India and world.

Grammage Checking Kit in Baddi

Material like paper, paperboard, and fibreboard are base material for various useful products. Their selection for any application is completely dependent on their quality standards. It is checked before supply of any paper material that if it fulfils the demanded criteria of industry or not. GSM or Gram per square meter is the weight of paper which may sound very basic but is a vital quality factor. As per their use, they are categorized based on their properties and weight is also one of the categorization criteria. The processing, production team must assure that they are using the right machines for testing or calculating the GSM value of paper. Presto’s Grammage Kit deliver high precision testing as it is designed as per international test standards. The cutter is equipped with heavy duty German Cutting blades and the size of cut is fixed as per the standards, the balance machine uses higher technology based digital counter which produces a precise weight value. The GSM kit is now easily available in Baddi and other prime locations of India.

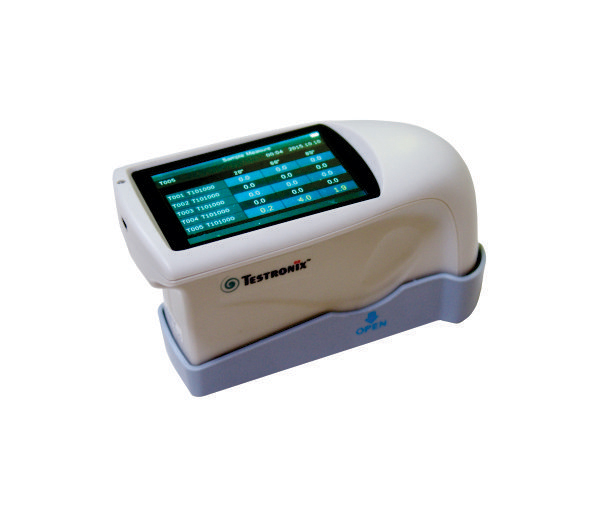

Spectrophotometer TP 800 - Color Matching in Baddi

Color has been always the most important criteria of every industry. Be it food, pharma, or plastic, color has always been playing their role. Hues, shades comparisons with master color, checking the consistency throughout the production are some major tasks which needs to be done in color quality control. Moreover, metamerism, natural phenomenon which interferes with color quality is also needs to be checked. TP 800 Spectrophotometer is designed to detect color and quantify it in precise based values. One can compare the color of products with master shade, user can see if the color is consistent all over the production. The device uses a software program with the help of which it can detect the color codes and save it in the memory instantly. The Device can be auto calibrated while switching on using white and black calibration program. User can see multiple test data ta one screen while testing to compare the data. The test values can be taken as a print out or can be extracted through USB portal. Get Spectrophotometer -Color Matching in Baddi with best technical features and advanced development.

Scuff Tester in Baddi

With time, packaging industries have started working on their appearances and have invested a lot to deliver the best aesthetics. Also manufacturers try to inform the consumers about their product by using interesting language which is also printed on the packaging cover. These print quality, and information which are printed on the package is always plays a vital role to the brand reputation. Therefore, manufacturers must have a quality check on the packaging material. As, while handling, storage and even in transit conditions, the material can face rubbing, or scuffing actions. This may lead to loss of printing quality or data written on it. Thus, a Scuff testing machine can be used to stimulate the rubbing conditions and see how much rotation of scuff the specimen can take without destroying the print quality. The machine is equipped with a motorised flat circular fixture which deliver continuous rotations. And the rotations are precisely counted by the digital program. Purchase Scuff Tester in Baddi now, just connect with our team and get quotation.

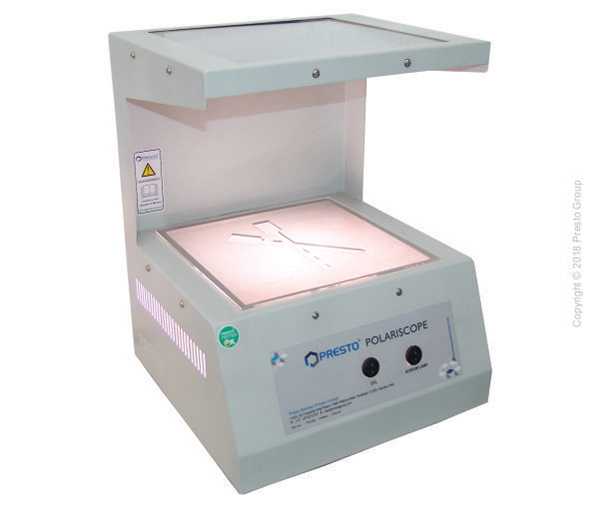

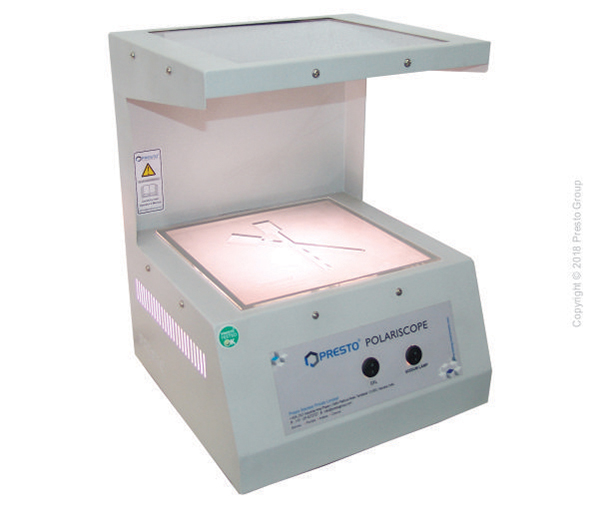

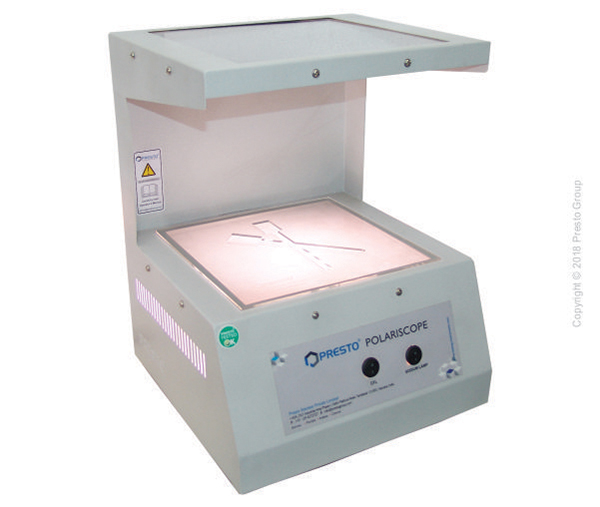

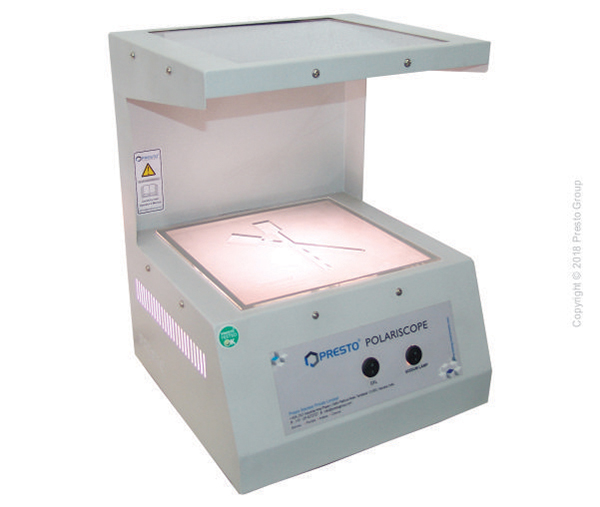

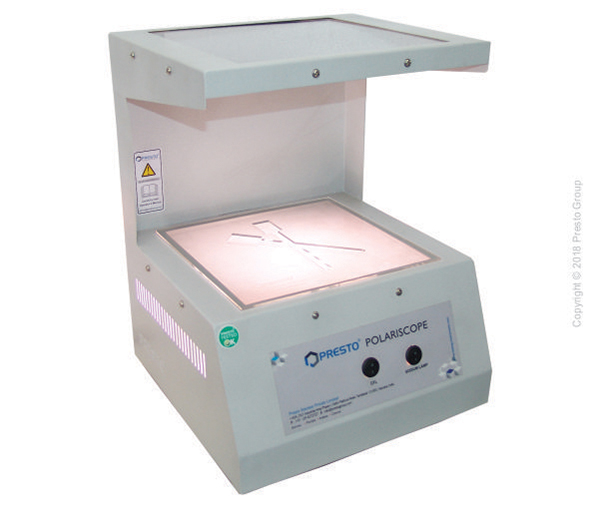

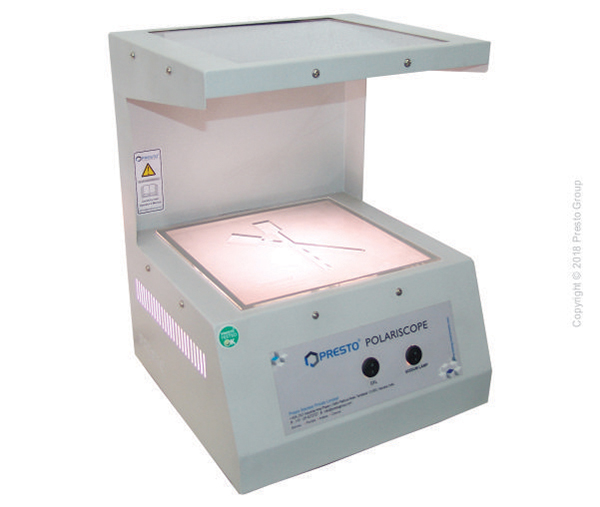

Polariscope in Baddi

PET bottle are manufactured via blow moulding technique. This process involves melting of PET material and then pouring of the material into Preform structures. These shapes are first cooled down and the taken for multiple testing procedures. As it is believed that if the PET preform is OK as per the quality standards, the bottle manufactured further will also be as per the criteria set. The preform while heating, melting cooling process sometimes gets stress or strain distribution on its surface which is not corrected can deliver damaging quality outputs in the final bottles. As these defects cannot be seen through naked eyes, Polariscope strain inspecting machine is used. The machine has two special lights equipped – Monochromatic light and sodium light. Under these lighting conditions the defects are visualized clearly. The base platform used for testing has angular standard template at 90 and 45 degree angle. Get Polariscope in Baddi by connecting with us today.

Peel Strength tester in Baddi

The adhesive bonds between the pressure sensitive tapes and self-adhesive films are often inspected for their bond strength in between as the main function of the material is to deliver strong adhesion and if due to poor bond strength they fail, they are of no use to the customer. Therefore, the manufacturers seek strict quality controls over the materials and they are inspected under peeling forces. Peeling test machine, designed by presto can inspect adhesion strength and peel strength both. The sample is clamped in between two fixtures which are designed to deliver strong hold on the specimen as they must not get disturbed during the test procedures. After that, the specimen is pulled from both ends to peel it off and the force applied is calculated. It is inspected that at how much force the adhesive bonds can be broken or how much amount of peeling force it can sustain. Get the ultimate testing solution for adhesive quality control. Purchase Peel Strength tester from Baddi and improve quality standards.

Melt Flow Index Tester in Baddi

The Polymer melt flow properties plays a major role in deciding the quality standards of plastic material and also for its categorization as per the application. The polymer’s melt flow behaviour is vital for assessing its thermal nature and its processing procedures. The melt flow index (MFI) is the rate of flowing of a molten polymer which is extruded from a heated barrel under a defined pressure and temperature within 10 min of time interval. Other than MFI, MFR and MVR can also be calculated using specially design testing machine – Melt flow Index testing Equipment. The device is equipped with a huge barrel ideal for heating the polymer granules. Pistons for applying pressure on the material and range of distinct weights is also available. The cutting of the molten polymer flown is automated ensuring zero error in the test data. The machine offers PID temperature controller for a control over the heating conditions and digital display screen which show the values for heat and pressure. To purchase Melt Flow Index Tester in Baddi, Connect with our team today.

Laboratory Hot Air Oven in Baddi

The plastic industry is the most competitive industry of all and demands the best day by day. To lead the market you have to assure your customers that the product you are supplying is resistant to several conditions and are strong enough to be the same for a long time validity. For this the plastic products undergo many quality test procedures. Most of them require dry heat procedure in a controlled manner. Tests like dry heat sterilization, ageing process, heat deformation test, heat resistance in polymers etc. requires use of industrial oven. The chamber is made up of mild steel material which is of a high grade quality. The digital display on the machine is microprocessor based and is highly accurate in digital conversions of heating temperature. PID controller assures high precision in heating procedure. The specimen placement trays are kept at standard design. There is an air circulation fan equipped in the chamber which ensure that the heated environment do not gets steady at one place and must be uniform at each and all corners of the chambers. Interested clients can purchase Laboratory Hot Air Oven from Baddi and also from other top industrial location of India.

Vacuum Leak Tester in Baddi

PET bottles or containers are popularly utilized for packaging purpose in various industries like food, pharma and beverages. It can also be utilized in chemical industries as well. While being used for carrying such vital contents, they are expected to provide a sealed conditions to the inside content and protect them from the surrounding contaminants. This can be only achieved with a Leakage proof material used for manufacturing PET bottle. And to check the quality of the PET bottle and see that if it is matching the requirements or are as per the industry concern or not, one must making use of strict quality control equipment like Vacuum test chambers for PET bottles. The chamber is equipped with an acrylic clear and strong chamber which is fitted to a mild steel base. The base has a pressure gauge and digital display screen to monitor the Vacuum changes and test data. The medium for testing PET containers inside the chamber can be liquid or dry Vacuum. The Vacuum decay method is the most perform test of PET bottles. Connect with our team and get Vacuum Leak Tester in Baddi and other prime locations of India.

Gloss Meter Triangle in Baddi

Gloss is an important decorative factor of various material surface. It is the reflection of light which falls on the surface which creates the shine and gloss to the viewer. Mostly people believe that shining is a selling factor and more of it is good for sale. But it is not case everywhere. Too much of gloss may interfere with the printing quality or even the original color. And too low gloss can make the product look dull compared to others. Hence it is very important that the gloss shine must be fixed as per the industry standards. The easiest method to do so is first quantifying the gloss using a Gloss meter. The device is equipped with a huge touch screen display which is both utilized for operation and test monitoring. It is very simple to detect the gloss value of sample. Just place the device flat on the material surface and the gloss or shine is automatically detected. One can perform repeatable testing on different region of same surface to see if the material is producing same quantity of gloss throughout the material or not. It detect gloss on three angular mode - at 20 degree, 60 degree and at 85 degree. Gloss Meter Triangle can be easily available in Baddi. Just connect with our team and get the ultimate testing solution for your help.

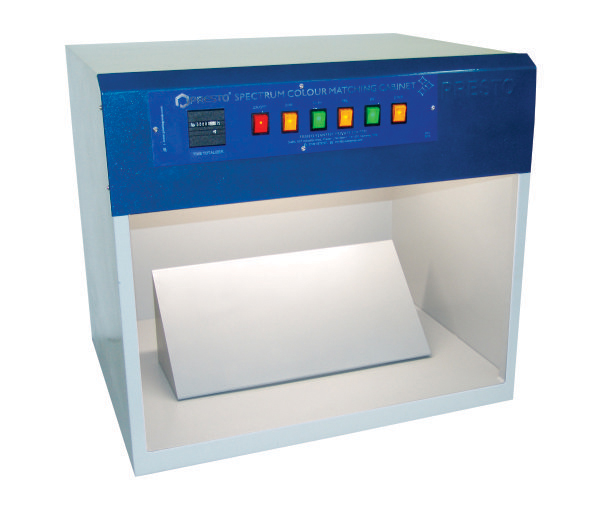

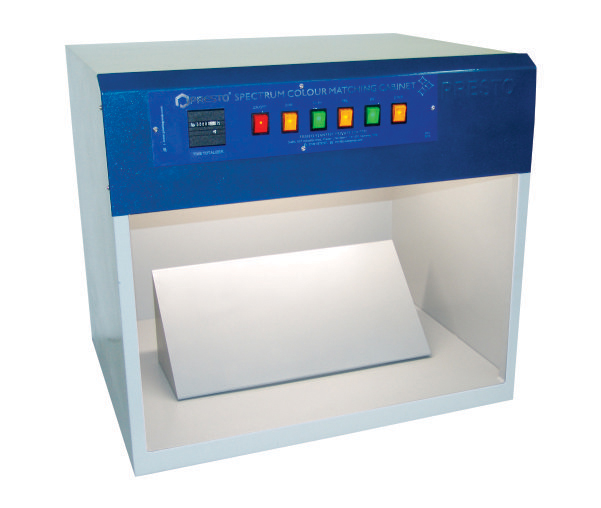

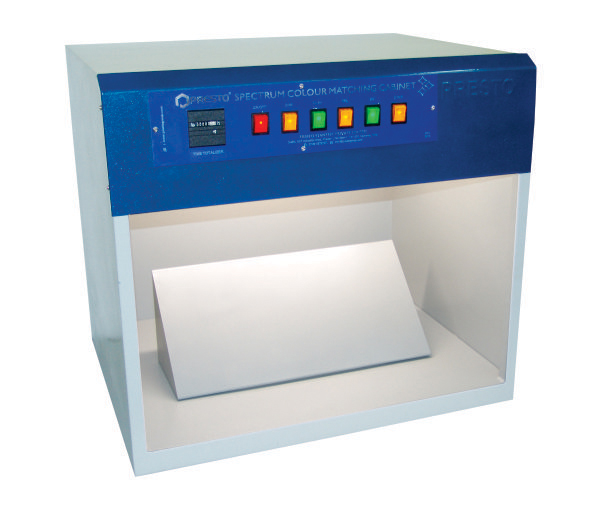

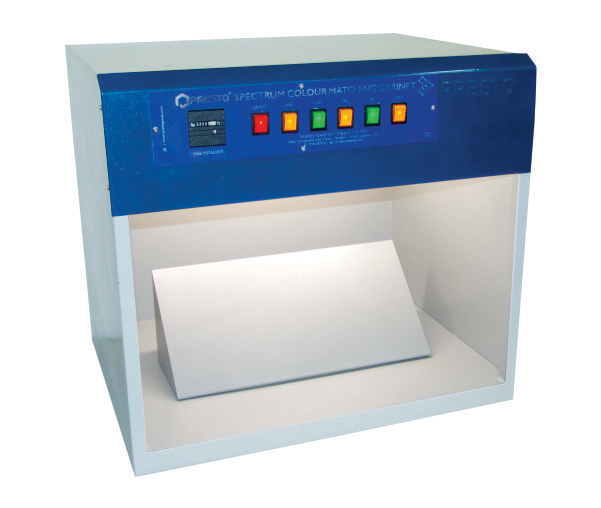

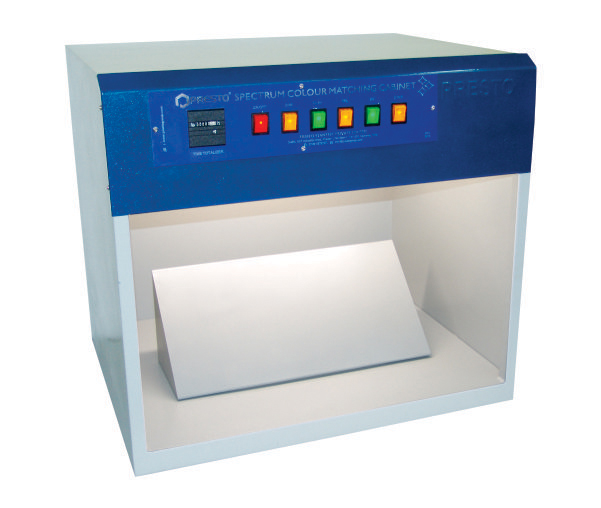

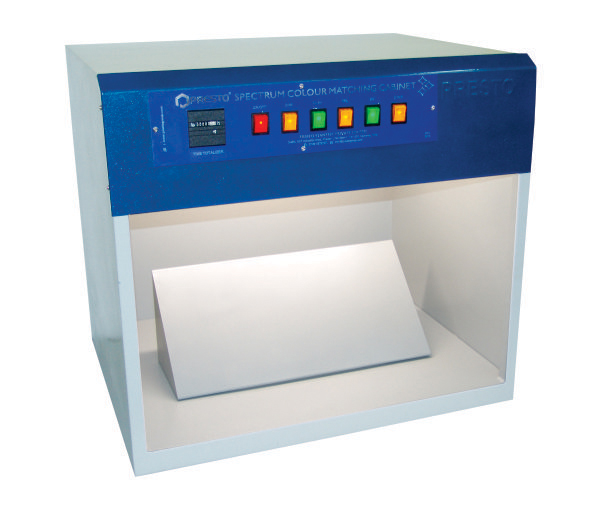

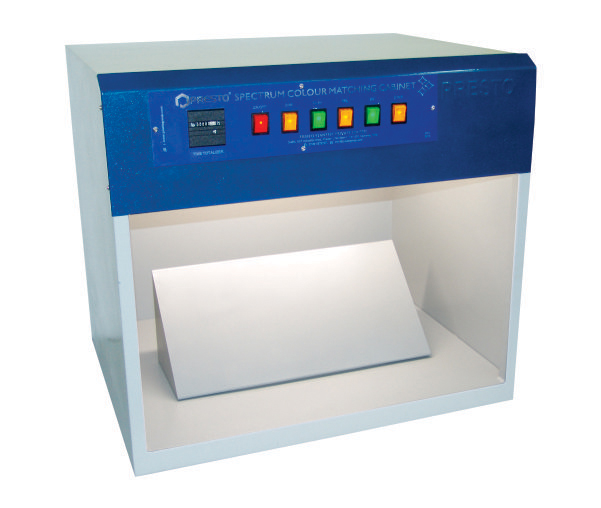

Color Matching Cabinet in Baddi

Metamerism is a natural phenomenon according to which a color may appear different under distinct lighting conditions. Red may appear the same under day light but may get the appearance of orange under fluorescent light. For instance a product bought by a customer was a red purse but on receiving the color is not bright red but appear as orange. Instantly the customer will reject the product and ban the manufacturing company and even the marketer from their list. This small color quality check can save you the loss of getting removed from the favourite list of customers. The Color Light box is equipped with 5 different lighting conditions which are required to check a product manufacturer or market in Asia. The lights includes - D 65 Artificial Daylight, TL 84 Triphosphor Fluorescent Light, UV Black light, TFL Tungsten Filament Light, and CWF Cool White Light. Also the chamber is equipped with an angular platform to keep the specimen to be seen. The platform is designed as per test standards and situated at an angle of 45 degree. Interested Clients can have Color Matching Cabinet in Baddi and in other locations of India.

Salt Spray Chamber in Mumbai

Coating, paint and plating are applied to products to protect the outmost surface from outside salt laden conditions. The coated surface may be exposed to air or water, in both cases, the material can get easily damaged with corrosive actions in the absence of an efficient coating system. Thus, using a coating layer for an application which can deliver maximum protection and stay for long is preferred. For testing the quality of coating system they are put under salt fog test using a Salt spray tester. The test chamber generates a salt fog simulating the corrosive environment and will deliver the effect of a thousand years in few hours of testing. It is equipped with special features like HMI based touchscreen display which is used for test programming, test data recording and for monitoring live test conditions. It also allows Ethernet connectivity for user computers so that one can connect their device to the running test chamber. The corrosion chamber is triple walled using fibre reinforced material. This ensures zero heat and temperature loss during the test cycle. Get Salt Spray Chamber in Mumbai by contacting and letting us serve your testing needs better.

Polariscope in Mumbai

The PET bottle is manufactured under a blow moulding technique. In this method, the PET material is melted down and poured into the preform castings. The preform is then cooled down. This preform structure is then taken for the quality testing. It is considered that of the preform clears the quality test then the bottle which will be further blow moulded using the preform will also be as per the required standards. The most concerned issue is the stress and strain distribution on the surface and wall of the PER preform structures. The Preform can be tested under the Polariscope strain viewer. The machine is equipped with two light sources, i.e. sodium light and monochromatic light under this lighting condition the defects are viewed. These defects often appear as patterns which can be then compared with preform defects chart. The preform is tested by keeping at standard angle template i.e. at 45 and 90-degree angle. Get Polariscope in Mumbai by getting in touch with our branch in Maharashtra.

Scuff Tester in Mumbai

The printed packaging or inked data on containers and boxes plays a vital role in transferring information from the company to the customers or to the retailer. The data can contain handling information, transporting information, ingredients and dates of manufacturing, expiry etc. These data holds a lot of importance and must be retained on the package for long. But during the manufacturing process, handling packaging, and even while storage and in the retailers shop the printed data may face the rubbing and scuff on the surface. Therefore, it is must to test that the material which is printed is retaining the data or not. The scuff testing machine is equipped with a scuff generating head which contacts the surface of the test specimen and rubs against it in rotations. The digital display screen counts the rotations performed and the result is visually inspected. The machine can perform standard rubbing action on the sample and the microprocessor-based program maintains the accuracy in the motion and rotation counts. Get Scuff Tester in Mumbai with advanced features and technology.

Peel Strength tester in Mumbai

The adhesive materials are categorized as per their quality standards and in case of adhesive material the bond strength, the resistance to peeling forces are the properties which are checked. The adhesion strength or the bond strength plays a major role when the securing of packages depends on the sealing of a particular adhesion film. In cases of tapes and packages, the adhesion must be maintained as per the industry demand. To test the quality standards of adhesive material, peel strength testing machine can be used. The tester is equipped with a digitalized display screen which accurately converts the forces exerted into digital format. The screen is lit with a bright LED light for low light vision. The machine has a special type of grips to clamp the specimen strongly and ensure that it does not get slipped during the test. The machine is designed as per various international standards. Purchase Peel Strength tester from Mumbai and experience the best testing solution for your industry.

Laboratory Hot Air Oven in Mumbai

Plastic material or components used in manufacturing units must be categorized as per their quality standards. This categorization is done by testing the behaviour and properties of polymers or plastic products under distinct conditions. Some major test processes are ageing process, weathering test, heat deflection test etc. Also in some labs, dry heat is used for sterilization of lab equipment. The Industrial hot air oven is specially designed to fulfil the industry demands and testing the behaviour of the material under elevating dry heat. The machine is equipped with a microprocessor-based digital display screen and feather touch control buttons used to set test values such as temperature, time period etc. The chamber offers two specimen placement trays for easy specimen placing. High-grade fans for circulating the heat uniformly throughout the chamber so that the heat is maintained at all sections of the chamber equally. You can easily have the Laboratory Hot Air Oven in Mumbai. Just contact our team for a quotation.

Box Compression Tester in Mumbai

Corrugated boxes are popularly used for transportation, storage and other things which require immense resistance against the compressive load. For instance, transporting glasswares or sensitive items to distant locations may require the box to be strong enough to protect the content inside from the compressive load experienced. The boxes are kept one upon another in the shipping or airline storage area. In such situation, it is easy to get buckled under so much of pressure. This particular property requires to be tested that how much load a particular box can take and as per that the box may be used for a particular application. The compression tester is a digital model, equipped with a digital display screen which records the compression force precisely. The machine offers a strong compression plate which is equipped with a load cell that will help in distribution of the compressive load uniformly on the specimen box. Get Box Compression Tester in Mumbai by contacting our team at your nearest location.

Edge Crush Tester in Mumbai

Carton boxes or corrugated boxes are popularly used for packaging purpose and in storage. They are also used for transporting products widely. During fulfilling these purposes they are expected to retain maximum strength and resistance against the compressive forces. The box material which is mostly fibreboard must deliver strength as expected as per application. Use of edge crush strength tester can help in determining the crush strength of the corrugated box material. The testing equipment is loaded with lots of features and advanced technology. Equipped with a NABL certified calibrated load cell which is used to distribute the crushing load equally on the specimen. The digital display screen on the machine is based on a high-tech microprocessor program which records the test value accurately. There are safety limit switches which limit the travel length of the testing space. Introduce a leading testing solution to your company by having Edge Crush Tester, now available in Mumbai.

Tensile Testing Machine in Mumbai

All types of Plastic Material have a defined tensile strength of their own depending upon their making process and composition. Tensile strength is a very vital property of plastic and manufacturers decide their further use and categorize them as per this property. That is why it is must to have a testing apparatus which can precisely record the tensile strength. Tensile test machine by Presto is designed as per international test standards. The machine has a load cell equipped with the testing apparatus to distribute the pulling force equally on the specimen. The grips offered are standardly vice type but other forms of grips are also allowed to be purchased with the equipment as per the customer’s choice. Safety limit switches are equipped to implement limitations in the travel length while testing. The force is recorded on the digital display screen which is based on a high –technological microprocessor program. Access the best testing solution for estimating plastic tensile strength with Tensile Testing Machine in Mumbai and in other prime locations.

Wall thickness Gauge - Magna Mike 8600 in Mumbai

Measuring the wall thickness of products, material or components is a very complicated system and requires a precision based calculation. Non-ferrous objects like plastic and glass are often used as an important part of huge machinery or products like in aerospace, packaging, and automotive industry. The wall thickness measurements are taken using Magnamike 8600. The device is equipped with a huge LCD screen which instantly records thickness readings. It is designed as per a highly integrated software program. The measuring probe head is also offered in varieties and also the target can be used as ball, disc or wire. The measuring process can be initiated by placing any type of target inside the specimen depending upon the product. Then bring the probe near the external surface and the other side of the target. The distance between the target and the probe is measured using the magnetic interaction and it will be the accurate value for thickness. Purchase Wall thickness Gauge – Magna Mike 8600 in Mumbai and get the ideal testing solution on your doorsteps.

Grammage Checking Kit in Mumbai

Raw material such as paper, fibreboard, and paperboard are often used as the basic material for manufacturing various products such as paper bags, paperboard carton box etc. The selection for their application is entirely based upon their standard of quality. It is always examined that the raw paper sample is fulfilling the requirements of industry or not prior dispatch. Unit of measurement for paper weight is GSM or Gram per square meter which may mean very simple to someone but is an important quality criterion for industries. As per their utilization, they are categorized depending on their features and weight. The processing, production team must ensure their customers that they are implementing the correct instrumentation for evaluating or calculating the GSM factor of paper material. Presto’s Grammage Kit ensures higher accuracy in test results as it is constructed as per international test standards. The round cutter uses heavy-duty German imported Cutting blades and the way of cutting the paper is circular in shape which is set as per test standards, and the digital balance machine utilizes advanced digital technology with a counter which delivers a precision based GSM value. The Grammage Checking Kit in Mumbai is now available with other prime locations of India.

Humidity Test Chambers in Mumbai

Humidity testing chamber is utilized by distinct industries for evaluating the quality of their raw material or main product under artificially controlled humid conditions and modifying temperature. It can be utilized for testing the behaviour of extreme humid conditions on the product for a long time span. The chambers are equipped with German imported air Circulation fan for uniform circulation of air inside the chamber. The testing environment is controlled digitally utilizing a microprocessor-based program and also has a digital display for accurate recording. The sample keeping area has a huge amount of space for testing various sizes and shapes. The test environment can be easily operated and programmed by the operator. The test results are visually examined post-test completion. A PID temperature controller is also a part of the equipment for delivering precision in temperature. Can be utilized for testing resistance strength of a coating or uncoated specimen against controlled humid conditions. The Humidity Test Chambers is available in Mumbai and in another top most industrial regions across the nation.

Hot Wire Bottle Cutter in Mumbai

The bottle cutting machine is a unique testing machine which is utilized for slicing PET bottle in three parts. The cut sections of the bottle are further utilized for conducting quality control examination like section weight assessment. In this test process, the bottle is sliced into three precise sections i.e. top, middle and bottom parts and weighed separately. It is believed that the separate weight of the bottle must match the industry requirement and in case they are not fulfilling the criteria, then there must be a quality defect and the PET bottle is directly rejected. Therefore, the machine utilized for cutting of PET bottles must deliver precision while slicing. Hot wire bottle cutting machine is fitted with a high standard of Kanthal wires which is used for cutting the sample. It assures that the area of sections which are sliced will be highly accurate and will not leave uneven edges. Interested clients can place a purchase order for Hot Wire Bottle Cutter from Mumbai and other vital industrial towns of India.

Top Load Tester in Mumbai

PET bottle or containers are kept on one over the other in warehouses and also while they are in transit situations. Especially when the PET containers are placed at such a similar position for a long time period, the bottle kept at the base can experience buckling. This situation usually appears when the bottle packaging is either moved from one location to other or kept in warehouses for a long time period. The amount of pressure faced by the bottle specimen at the base will force it to develop cracks or may also get burst leading to a content loss. To avoid such type of situations, manufacturers must ensure that the Bottles are strong enough to resist a defined amount of top load. To test the strength under increasing load one can use Presto’s Top load testing machine. The machine is fitted with inverted straight plates which put a vertical compressive load on the specimen and a load cell is equipped to uniformly distribute the pressure. Digital display screen delivers test data with complete accuracy and high precision. Interested clients can now have Top Load Tester in Mumbai along with other top industrial towns of India.

Color Matching Cabinet in Mumbai

Metamerism is a nature’s phenomenon as per which a particular product may appear different under changing lighting conditions. Red may look the same under fluorescent light but may look orange under sunlight. For example, a product purchased by a customer was of red color but on arrival, the color appears as orange. Immediately the customer will reject the product and the brand and even the marketer of the product from their list. This color quality inspection can save you from losing reputation and from getting removed from the favourite list of your target customers. The Color Light box is fitted with 5 distinct lighting conditions which are required to inspect a product as per Asia standards. The lights equipped are - D 65 Artificial Daylight, TL 84 Triphosphor Fluorescent Light, UV Black light, TFL Tungsten Filament Light, and CWF Cool White Light. Also, the chamber is fitted with a 45-degree angular platform to place the specimen during the test. Interested Clients can have Color Matching Cabinet in Mumbai and in other locations of India.

Gloss Meter Triangle in Mumbai

The gloss is a vital and an aesthetic factor for many material surfaces. It is the light which falls on the material and reflection comes from the surfaces which generate the shine or gloss for the viewer. Most of the people believe that the glossy surface is a major selling point and more the gloss, better will be the sale. But it is not the case for everything. Sometimes excessive gloss may disturb the printing quality or even the original shade. And too much dullness can make the product look off compared to others. Therefore, it is very vital that the gloss of the surface must be fixed as per the industry criteria. The simplest test method for this is quantifying the gloss factor using a precise Gloss meter. The device is fitted with an HMI based touch screen display which is used for both test programming and test monitoring. To test the surface gloss, just place the specimen under the device and the gloss will be automatically estimated. One can conduct repeatable testing on a distinct area of the same product to compare the gloss consistency throughout the material. It can inspect gloss via three angles - at 20 degrees, 60 degrees and at 85 degrees. Gloss Meter Triangle can be easily available in Mumbai. Just contact our team and get the ideal testing solution.

Vacuum Leak Tester in Mumbai

PET bottles or vessels are widely used in packaging industry like food, pharma and beverages. It can also be used in chemical factories as well due to their non-reactive nature. While being utilized for carrying out such important contents, they are expected to deliver sealed conditions for the inside content and protect them from the outer contaminants. This can be only done by using a Leakage proof material for manufacturing a PET bottle. And to inspect the quality of the PET container and ensure that the product is fulfilling the industry requirements or are as per the industry application or not, one must use strict quality control equipment like Vacuum test chambers for testing PET bottles leakage quality. The chamber is fitted with an acrylic material which is clear and strong. The chamber which is fitted on mild steel base is designed as per international leak test standards. The base machine is fitted with a pressure gauge and a digitally controlled display screen to monitor the Vacuum pressure changes and test value. The medium used for testing PET containers inside the chamber can be liquid or dry air. The Vacuum decay test method is the most performed test on PET bottles. Connect with our team and get Vacuum Leak Tester in Mumbai and other prime locations of India.

Melt Flow Index Tester in Mumbai

The Plastic melt flow properties holds a major role in determining the quality standards of polymer granules and also for its distribution as per the application decided. The plastic’s melt flow behaviour is important for estimating its thermal and melting nature and also it’s processing method. The melt flow index (MFI) is defined as the rate of flowing in a melted polymer which is extruded from a high-temperature barrel under a prefixed pressure and temperature within 10 min of time span. Other than MFI, MFR and MVR values can also be estimated utilizing the testing machine – Melt flow Index tester. The device is fitted with a big sized barrel which is considered ideal for heating the polymer granules till it gets molten. Pistons are there for application of pressure on the molten granule and range of distinct weights is also available to program the pressure as per industry requirement. The cutting of the molten polymer flown is automatically controlled assuring zero error in estimation of testing data. The machine delivers PID temperature controller for precise heating conditions and a digital display screen which records the heat and pressure values accurately. To purchase Melt Flow Index Tester in Mumbai, get in touch with our team today.

Grammage Checking Kit in Bangalore

GSM value of paper and packaging paper or films is a very important quality factor. Based upon this the manufacturers categorize the paper samples for their further applications. The GSM kit is a combination of a cutting machine and a digital balance. The cutter is designed as per test standards and cuts repeatable time at the same diameter. It also has German Imported heavy duty cutting blades for the precision-based cutting process. It is also available with safety latch facility. The digital balance machine is equipped with a superior level of shock resistance and has overload protection, User can lock the software whenever required and also it has an integrated transportation locking feature. It is fitted with an Adjustable footrest with level indicator for assuring zero error in the test results. Get Grammage Checking Kit in Bangalore and across the nation. Just connect with our team today.

Humidity Test Chambers in Bangalore

The relative humidity combined with elevating temperature conditions sometimes leads to the destruction of coated material, plastic parts, etc. They interact with the outer surface leading to the removal of it and may expose the damaged material to corrosive air. Therefore, it is very important that these coatings systems or other products which can get affected by humid conditions must be checked prior to its supply to customers. The Humidity test chambers are utilized for behaviour inspection under humid and temperature conditions. The machine is fitted with digital temperature and humidity control system. The high-speed rapid circulation fan is there for uniform distribution of the test conditions. The fan is imported from Germany and specially designed as per test standards. The chamber complies with ASTM D1776 and ASTM D1776M-15 The temperature sensing is done with highly advanced PT – 100 sensor equipped in the chamber. Purchase Humidity Test Chambers in Bangalore for experiencing best humid test conditions.

Hot Wire Bottle Cutter in Bangalore

The PET bottle section weight assessment is an important quality test which determines the weight of a distinct section of PET bottle separately. For this assessment to be done it is vital that the sections are cut with high precision and no uneven edge must be there. The disturbed cutting of specimen may interfere with the weight measurement and lead to error in test results. Hot wire bottle cutting machine is designed by Presto Group and is renowned for its high precision performance. It is equipped with variable voltage potentiometer which controls the voltage running while test process. A digital display screen is there which display the heating temperature of the cutting wire. Specially designed bottle neck holder for clamping the PET bottle specimen strongly so that the slicing process can be firm. The Kanthal wire is rapidly heated and at once ready for the slicing procedure. Access the Hot Wire Bottle Cutter in Bangalore and get ideal testing solutions.

Top Load Tester in Bangalore

PET bottle packaging is a widely used item for food and beverage and even in pharma. Other than that it is utilized for many other chemical solutions. They are preferred over another type of material due to their non-reactive nature towards most of the products. Since PET containers are used for various packaging areas they must assure a top level of quality. The most common test conducted on them is the compressive load test. For transit or storage the bottles are often placed one over the other and in such condition, the bottles kept at the base if not strong enough will easily buckle and story the shape. Thus, rejection of the bottle. Therefore, it is prescribed that the bottles must be prior checked for its tolerance level against the vertical load. Top load testing machine is designed to deliver the same elevating compression load on PET bottles for testing their resistance strength. The machine equipped with inverted straight compression plates for exerting the compressive load. It is controlled by a digital microprocessor program and assures uniform and precise load exertion on the sample. Get Top Load Tester in Bangalore with special and advanced features.

Color Matching Cabinet in Bangalore

As per a natural optical phenomenon, Metamerism one colour may look different under distinct lighting conditions. This can disturb the colour quality of the products and sale. Hence, it is important for the manufacturers that before supplying your product to customers, they must check if their colour is consistent under distinct light sources. To test this one may use the leading test chamber, D65 light box by Presto Stantest. The viewing booth size is customizable as per client requirements. It is made up of high-grade steel material and plated with corrosion resistant paint for long-run performance. Equipped with 5 standard light sources under which the colour can be checked if the appearance is consistent or not. The sample placement area is also tilted to 45 degrees as per the standard design. Get Color Matching Cabinet in Bangalore with full technical support.

Gloss Meter Triangle in Bangalore

The gloss is an important factor of selling for manufacturers. It is believed that the shining light on the material surface declares its good quality and fine finishing. This is true as per the marketing strategies. The customer purchasing decision depends a lot on the appearance of the products. Therefore, it is important to take good care of the amount of gloss appearing on the surface. The gloss is often tested to be fixed as per the industry requirements. To test the gloss reflection, a device like Gloss Meter is utilized. The device is standardized as per international test standards including ASTM D2457, ASTM D523, ISO2813, and GB/T 9754. Equipped with an HMI based huge touchscreen, which is used for monitoring the test results at the same time captured. Also, one can program the test and compare multiple test value on one screen. The test results are calculated based upon a software program. It provides triple angular measurement i.e. at 20 degrees, 60 degrees and at 85 degrees. The user can also calibrate the tester as per its requirement automatically. One can now have Gloss Meter Triangle in Bangalore and across other major cities of India.

Vacuum Leak Tester in Bangalore

The PET bottles are made with high-grade material and are renowned for their non-reactive properties. The Bottles and container are tested for their resistance towards increasing vacuum pressure and leakage by using Vacuum chambers. The tester is equipped with a strong acrylic chamber which is transparent in nature. So that the test process can be checked and seen that if the material is leaking or not. The medium used for testing can be both water and air but mostly the water medium is chosen. The pressure is controlled by a gauge and a digital display is equipped to note the test data. The test process is equipped with a smart and precise microprocessor program so that accuracy can be maintained. The appearance of the bubble is the failure of the product which is tested. Purchase Vacuum Leak Tester in Bangalore with complete technical support.

Melt Flow Index Tester in Bangalore

The molten properties of plastic granules is an important feature. It is used to examine the quality and the estimate the behaviour of the polymer during its processing method. The flow of the melted plastic must be as per the industry requirements and the application it is subjected to. This particular feature is tested using Melt flow testing machine. The equipment is fitted with a PID controller which maintains the accuracy of the modifying temperature and heat generation. A pre-set digital timer for setting the time of the test process. On the top of the machine operator can place the weight of choice. The machine offers distinct weight for applying on the piston. The piston is used for pushing the sample and exerting pressure. The piston is inserted inside the barrel which is made up of high-grade material and is thick enough to control heat loss. Below the piston rests the sample which is melted and is flown outside. At the outer area, an automated cutter is equipped which cuts down the molten sample after 10 mins of flow. Now order Melt Flow Index Tester in Bangalore and get an ideal testing solution for your industries.

Box Compression Tester in Bangalore

The corrugated boxes which are used for packaging or storage purpose must be tested against elevating compressive load. The high-quality carton box manufacturer ensures that their packages can face extreme loads for a long time period. To test the quality standards of carton boxes, the only reliable testing solution will be Box compression tester – Digital model. The machine is designed by Presto Stantest and is supplied to all regions of India. Box Compression Tester is also supplied in Bangalore. The test machine is equipped with a twin column and is rugged structure. Has a strong compression plate which is used to exert a vertical load on the specimen boxes. When the machine is switched and commanded to push the plate automatically moves down till the command is not aborted. The compression plate is equipped with a load cell which ensures that the compression force is distributed on the specimen equally and uniformly at each corner of the box.

Tensile Testing Machine in Bangalore

The plastic material has a variety of property that can be calculated for its quality control. Tensile strength is one of them. Depending on the resistance strength of the material against tensile forces. Tensile tester is used for estimating the tensile quality of the material. It is equipped with a single column for low load testing. It is fitted with safety limit switches so that user can limit the travel length as per their industrial requirement. By fixing the length they can assure that the test results will be as per their criteria. The operation are controlled using a digital section which has a digital display screen fitted with a bright LED light for low light vision. The operation section is based on a microprocessor program. The testing fixtures are specially designed to deliver tight clamping so that the sample do not get loosen up while testing and it ensure zero error in test results. Get Tensile Testing Machine in Bangalore and other major industrial regions of India.

Wall thickness Gauge - Magna Mike 8600 in Bangalore

The wall thickness of a material is an important factor to test in several industries. Depending upon which the functions and performance of the product is defined. In some industries like aerospace it is so critical that the wrong reading of wall thickness can lead to severe accidents. Magnamike 8600 is a popular wall thickness gauge by the reputable brand Olympus. Presto is an authorized seller of the device in India. It is equipped with a large sized VGA display screen which shows the rapid calculations of the thickness reading. A magnetic probe which has several tips as per the product to be tested. The test data can be easily extracted on excel format. It can conduct reliable and repeatable measurements without failure and deliver error free results. The probe has a hall-effect sensor which accurately measures the thickness. The measurement is conducted by entering target inside the specimen which can be a ball, wore or disc. Get Wall thickness Gauge – Magna Mike 8600 in Bangalore with all the needful technical support.

Salt Spray Chamber in Bangalore

The corrosive environment reacts with the coating and try to damage it. Once the coating is out, the corrosion can directly react with the surface and then starts the oxidation reaction. This will not only hamper the Material itself but also the overall function and performance. Thus, it is very important now to have a reality check on the coating on which the company wish to invest. It is tested before that how much of salt laden conditions can a coating sustain and for how long. This estimation can help the user to choose wisely. The salt spray tester is equipped with a pneumatically controlled canopy which is designed precisely as per test standards. The angle of canopy is built in such a way that the evaporated droplet on the canopy will never fall direct on the sample but will slide down the canopy and fall inside the chamber. Fiber reinforced triple walled body which ensure zero heat loss increasing the testing efficiency. Get Salt Spray Chamber in Bangalore and across major cities of India.

Bursting Strength Tester in Bangalore

Paperboard material are tested for various factors and properties including the bursting strength of the material. The bursting factor or bursting index is also a part of the same quality control test. It is seen that at how much bursting force a particular material will burst out. This test will require the best testing solution which is Bursting Strength testing machine. Equipped with a manual operating wheel which helps the user to adjust the compressing load as per requirement. There are strong sample gripping clamps which holds the specimen tightly. On the base of test area, the area is grooved to generate friction for ensuring the slippage is zero. Below that is fitted a flexible diaphragm, which inflates to develop the bursting pressure from below area. The load indicator is digitally controlled screen with bright LED light for low light vision. Single push button operation with easy handling. The operation is based on a highly advanced microprocessor program. Get Bursting Strength tester in Bangalore and experience ideal testing solution for determining bursting strength, factor and index.

Edge Crush Tester in Bangalore

Conducting the edge crush test or ECT on fibreboard material is vital for it quality standardization and categorization as per their respective application. Similarly performing Ring crush test (RCT) and flat crush test (FCT) on the specimen holds major importance in evaluating the quality of the material. The machine designed by presto can perform all the three tests by using distinct fixtures. The clamps are strong enough to assure zero slippage guarantee. With tight clamping it is ensured that the test sample will not move during the test leading to zero error. Other than this load cell is fitted on the travel length area. It assures uniform distribution of compression load on the product. Safety limit switches will help the user to limit the travel length of the fixtures and can be set as per the industry requirements. The controls are based on a microprocessor program which records accurate force value and display on a digital screen. Purchase Edge Crush Tester in Bangalore with all the required technical support.

Laboratory Hot Air Oven in Bangalore

The Plastic ageing process is often conducted in industries for quality control. The manufacturers observe the effect of elevating temperature on their product when exposed for long time duration. Other than this for conducting dry heat sterilization, Ovens are used. The Industrial Hot air oven, is a compact and robust model which has digital controls. The digital display screen is equipped with Microprocessor based program and PID temperature controller for maintaining temperature accuracy. Below that are control button which are feather soft and easy for controlling machine operations. The door has a firm handle which ensure the chamber is locked carefully. There is even a facility of ventilation provided on the chamber. It is equipped with a high speed air circulation fan which is imported specially from Germany. It assures that the temperature inside is uniformly distributed to each corner. Delivers high grade insulation with Glass wool insulation equipped. Get Laboratory Hot Air Oven in Bangalore and all across the country for an ultimate testing experience.

Peel Strength tester in Bangalore

The adhesion bond strength of sealing agents or adhesive tapes are tested under controlled peeling forces generated by the highly advanced testing equipment, Peel strength testing machine. The equipment is fitted with load cell which is certified and calibrated by NABL labs. The load cell is used to uniformly distribute the peeling force on the testing specimen. Also there are 25 mm wide strong gripping clamps to hold the specimen. The clamps are specially designed to assure zero slippage. It is equipped with safety limit switches which can limit the travel length of peeling when required as per industry standard. The test process is controlled with a microprocessor based program. Digital display screen is fitted on the machine for accurate display of test values. The fixtures work at 180 degree angle other than that 90 degree angle fixtures are also available on customer request. Get Peel Strength tester in Bangalore and all across the world.

Scuff Tester in Bangalore

When printed packages are rubbed against rough surfaces or against each other while handling, storage, or transporting, this can lead to color fastness or loss of printed design or data. This is a major issue, when for instance in any medicinal box, the data like the dosage and expiry date which have a huge importance for the customer is lost due to constant rubbing can be a big issue. To avoid such things, the sample must be tested under the same activity. It can be generated with the use of Scuff testing machine. The machine is digitally controlled with digital based counter which quantify the number of rubbing rotations. The sample test area has a flat circular metal piece which is used for rubbing the sample. Above that 2 Psi weight is exerted. The rotational movements are controlled with motorized weight arrangement for delivering noise free working environment. Get Scuff Tester in Bangalore and experience the best testing solution.

Polariscope in Bangalore

PET Preform while their manufacturing process which is blow moulding technique, can exhibit stresses and strain defects on their base or wall. Such defects can lead to issues in the final bottle production with disturbed appearance or imbalance issues. To inspect these defects the preform samples are tested under Polariscope strain viewer. The machine is equipped with two standard light sources under which these defects are clearly visualized. The light sources include monochromatic light, sodium lamp. It is based on the principle of if the preform contains stress defect the refractive index passing it will change its path and will generate a pattern. The defect patterns can be compared with the preform defect chart having all the patterns. The charts is standardized and can help in assessment of the issue. Get Polariscope in Bangalore with all the latest features.

Box Compression Tester in Pune

Now you can experience the ideal testing solution with Box Compression Tester in Pune, Maharashtra. Connect with our team for further process. The Corrugated boxes or carton boxes have various applications in the packaging industry other than that they are also preferred for transportation of the products within national or international borders. They are used because of their stability against the compressive load experienced while transportation, handling and storage in warehouses.

While the use of corrugated boxes they are often kept one on another. At such time the box placed on the base faces a maximum vertical load and if the boxes are transported to a far distant location then they have to be taking the load for a long time. Such a situation can lead to buckling of boxes and even bursting them out. This type of defects can be avoided with strict quality control over the carton boxes. The Box compression testing machine is used for simulating the real-life vertical load exertion on the corrugated boxes. The Digital model equipment is a twin column rugged structure and has a standardized compression plate which pushes the sample down to see at which points it initiates to buckle. Get Box Compression Tester in Pune and introduce the best quality control to your industries.

Bursting Strength Tester in Pune

The paper, paperboard, or plastic films material all share one similar property that is its bursting strength. The burst value of this material is one of the quality factors which is counted at the time of categorization. Therefore, measure the factors with the help of correct instrumentation can save your products from rejections or guide you towards the path of improvement. The Bursting strength testing machine is designed as per several globally acclaimed test standards ASTM D 3786-01, ASTM D 3786 – 80A, and ISO 1060 PART-1 1987. These test standards are followed worldwide for testing the burst strength of the material. The machine is digitally operated and is based upon a microprocessor program. A digital display screen is equipped which shows the recorded force values precisely. There is manual mode rotating wheel for setting the bursting pressure. The below sample gripping clamps are circular in shape and are pushed on the sample and tightened till it is not movable further. The base area where the sample is placed in a grooved structure to produce maximum friction. A diaphragm fixed below the clamp inflates and exert pressure on the sample until it gets burst. Get Bursting Strength tester in Pune with all the required technical support.

Color Matching Cabinet in Pune

The colour industry cannot rely on their eyes for testing the colour consistency throughout the production batch under distinct lights. Human eyes cannot guarantee if the colour consistency is maintained or not and also if metamerism will cause an issue for the product. For detection of such colour defects, one must conduct standardized testing with Color matching box. The cabinet is used for numerous things, the user can see if the product colour is matching with the master colour shade and if it is the same throughout the production. It can also show the product colour under all possible lighting conditions which are used in the Asian continent. The lights which are fitted in the chamber are - Artificial Daylight, Triphosphor Fluorescent Light, Ultra Violet Black Light, Tungsten Filament Light, and Cool White Light. Also, there is a standard angular platform designed in the cabinet to place the specimen for testing under lights. The cabinet is made up of high-grade steel material which is plated with corrosion-resistant plating. Get Color Matching Cabinet in Pune with all the technical feature.

Edge Crush Tester in Pune

The corrugated carton boxes are a good example of strong and rigid container boxes. They are used in large amount for transporting, storage and packaging or even marketing. The reliability over these boxes is high due to their maximum resistance against crushing load compared to others. The manufacturers of the carton boards must ensure that if they want to improve their sale they must work on improving the crush strength quality of their material. For that, they need to implement a strict quality check using Edge crush testing machine. The tester is designed as per international test standards such as IS 7063. It can perform all the three modes of testing crush strength that is – Ring crush test, edge crush test and flat crush test. For all these three tests, the machine uses distinct types of fixtures. The sample gripping clamps are strong enough to hold the specimen tight while the test process in on. This ensures that the sample will not move an inch while application of crushing load on it. Get Edge Crush Tester in Pune, just connect with our team.

Tensile Testing Machine in Pune

Plastic-based material is often used to manufacture important plastic products such as automotive parts or aerospace components, pharma caps etc. during its manufacturing process, they are stretched to form a particular shape. This stretched form is always under constant tensile stress. With time these stress increases, and can lead to marks, cracks, and even rupture of the product. To asses that how much tensile stress a product can take on it and sustain, they are tested using the tensile tester. The machine is designed as per international test standards including ASTM D412, ASTM D429-73, ASTM D624, ATM D638-01, ASTM D76, IS 13360-5-7, and IS 3400(Part1-1987). Its functions are based upon a microprocessor program. The technology very precisely records minute changes and records to display on the screen in digital format. It is also equipped with safety limit switches which are used to limit the travelling length, the specimen will then only be pulled till a fixed distance and not beyond that. Interested clients can now have Tensile Testing Machine in Pune with all type of technical support.

Wall thickness Gauge - Magna Mike 8600 in Pune

Non-ferrous materials, like glass, plastic, wood, non-ferrous metal etc. are widely used to manufacture vital products and used in applications. Their quality check also holds equal importance. Especially measuring the wall thickness of material to assure that they match the requirements. Magna Mike 8600 is an advanced wall thickness measurement solution followed by many market leaders. The device is a non-destructive tool which works on the principle of Hall effects sensor. The magnetic induction emits from the testing probe attract the ferrous target and the distance in between is noted as the material thickness. The probe has numerous forms of tips as per requirement. The targets are also of three types, balls, disc, and wires. The targets are placed inside the specimen and the probe is placed outside of the sample. The two meets at a point and joined from both ends with magnetic induction and are strongly attracted to each other. This way the wall thickness is measured. You can now get Wall thickness Gauge – Magna Mike 8600 in Pune. Just contact our team and get your request placed.

Salt Spray Chamber in Pune

The ferrous metals are always prone to the most damaging issue which is corrosion. That is why manufacturers apply the most efficient coating system which can sustain for maximum time in the corrosive air. Therefore, it is vital to know the validity of a coating and if it can survive under the expected condition for a particular material. Salt spray tester is one such environmental chamber which uses advanced technology to produce controlled salt fog under which the materials can be tested for its resistance against damage. The chamber is made up of triple walled fibre reinforced material which ensures that the heat or temperature during the test is not lost. It is equipped with an automated air purge technology which if pressed then the corrosive air will automatically settle down and then the chamber door will get opened. This way the corrosive air will not affect the surrounding conditions. Get Salt Spray Chamber in Pune and experience the ultimate testing solution.

Laboratory Hot Air Oven in Pune

The Plastics parts and components are tested under elevating dry heat for estimating the behaviour. The test chamber is equipped with German imported air circulating fans which distribute the heat overall the chamber so that the heat is reached to every corner of the chamber and the test specimen. The chamber uses digital technology which is based upon a microprocessor-based software. It assures precision based results in the testing process. The Digital display screen shows the temperature changes conducted inside. The screen is equipped with bright LED light which helps the user to view results in low light vision. The machine has huge space inside for specimen placement. It is fitted with SSR based heaters which produce the maximum level of heat. The hot air oven is used in plastic industries, research labs, and even in pharma industries. Interested clients can now access Laboratory Hot Air Oven in Pune with all the required technical support.

Peel Strength tester in Pune

The adhesive materials including pressure sensitive tapes or medical Band-Aids, self-adhesion packaging films etc. are must be checked for its bond strength quality. This can be performed using the peel strength testing machine. The tester is designed by Prestogroup and strictly adhere to ASTM D 903 test standard. It is equipped with a load cell which is certified with NABL labs and is used for distributing the force application uniformly on the test specimen. There are 25 mm width gripping clamps which hold the specimen from both ends to perform peeling activity. Also, there are safety limit switches, which bound the travel length for a specified distance. It uses a microprocessor based advanced digital display for showing accurate test result values. There is a 180-degree fixture already fitted in the machine and a 90-degree fixture can also be attained on request. It can take up to 20 Kgf capacity and has an accuracy of ± 2% at full load applied. Delivers a test speed of 300 mm/min± 5%. Now you can also access Peel Strength tester in Pune. Contact our team today.

Scuff Tester in Pune

Printed or coated material which can be a packaging film or paper, even printed newspaper or any magazine cover. Basically, any printed or coated surface which is open and can be exposed to rubbing with other surfaces may lose their print and colour quality. To test how much resistance it can provide against scuffing, Scuff testing machine is used. The tester is designed and constructed as per ASTM F2497-05, and BS 3110:1959 test standards. It is equipped with a 2 psi weight which is used for exerting pressure on the test sample and ensuring evenness in every test cycle. The sample test areas have a moving upper base which is connected with a motorised arrangement for noise-free and smooth rubbing movements. The machine is also equipped with a digital pre-set timer for counting the rotations. The machine delivers a precise simulation of the scuffing so that it can be seen clearly that how much a material can sustain and the results are visually inspected. Get Scuff Tester in Pune along with other prime locations of India.

Melt Flow Index Tester in Pune

The molten properties of plastic material is a vital feature. It is utilized for inspecting the quality standards and detect the behaviour of the polymer specimen during its processing or manufacturing method. The flow of the molten polymer material must be as per the industry criteria and the application it will be used for. This particular feature is estimated with Melt flow testing machine. The device is equipped with a PID temperature controller which maintains the precision in changing temperature and heat production. A pre-set digital timer for fixing the test time of the process. On the top of the machine, the user can place weight for applying pressure. The device provides different weight for delivering on the piston. The piston is utilized for pressing the sample and putting pressure. The piston is pushed inside the barrel which is built up of high-grade material and is thick enough to manage the heat loss. Below the piston, the sample is kept which is melted and is flown externally. At the external part, an automated cutter is fitted which cuts down the melted sample after 10 mins of flow. Now purchase Melt Flow Index Tester in Pune and get the best testing solution for polymer industries.

Vacuum Leak Tester in Pune

The PET bottles are built using high-class material and are famous for their non-reactive properties. The Bottles or container are examined for their tolerance level toward elevating vacuum pressure and leakage by utilizing Vacuum chambers. The tester is fitted with a tough acrylic chamber which is transparent in vision. So that the test process can be assessed and checked that if the specimen is leaking or not. The test medium utilized for testing can be both water and air but most of the time, water is chosen as a medium. The pressure is monitored by a gauge and a digitalized display is equipped to note the test data. The test process is fitted with advanced and precise microprocessor software so that accuracy can be noted. The appearance of the bubble is considered as product failure. Purchase Vacuum Leak Tester in Pune with full technical support and assistance.

Gloss Meter - Triangle in Pune

The gloss is a vital part for sale used by manufacturers of market leaders. It is noted that the gloss reflection on the product surface is the proof its surface quality and surface finishing. As per the marketing strategist, the gloss reflection plays an important role. The gloss impacts the customer buying decision and also the product appearance. Thus, it is important to note the gloss value precision based. The gloss meter is equipped with a large LCD screen which is used for both test results monitoring and programming test method. For instance, one can set the time, the parameters on which the test is to be performed etc. The detection section is on the base which smartly captures minute reflected rays from the surface. The device is made as per global test standards i.e. ASTM D2457, ASTM D523, ISO2813, and GB/T 9754. It can perform testing at three mode angles which are at 20 degrees, 60 and 85 degrees. The operator can also calibrate the tester as per their need and industry standards. One can now get Gloss Meter Triangle in Pune and across the globe.

Top Load Tester in Pune

Plastic bottle packaging is a widely utilized product for food and beverage industry and even in pharmaceuticals. Other than that it is used for carrying other types of chemicals. They are preferred over other containers because of their non-reactive nature. Since PET containers are utilized for a different type of packaging arenas, they must ensure the best standard of quality. The most usual inspection performed on PET bottles is the vertical compressive load test. For the purpose of transport or storage, the bottles are often kept one over the other and in such situation, the bottles which are placed at the end of the line will easily crack down. Thus, leading to rejection of the bottle production. Therefore, it is suggested that the bottles must be tested for its resistance strength under elevating vertical load. Top load testing machine is built to provide a similar compression load on plastic bottles which they may experience in the real world. The machine is fitted with inverted straight compression plates for putting a load on the specimen. It is controlled by a digital-based microprocessor software program and assures uniform distribution and precise load application on the test sample. Purchase Top Load Tester in Pune having unique and latest features.

Hot Wire Bottle Cutter in Pune

The section weight processing of Plastic bottle is a vital quality inspection step which helps in estimating the weight of separate sections of the bottle. For this inspection method to be accurate, it is important that the sliced parts are precisely cut and left zero uneven edges. The unequal slicing of the bottle parts may lead to error full weight measurement. Hot wire bottle cutting machine is constructed by Presto Group and is known for its highly accurate testing performance. It is fitted with a variable voltage potentiometer for controlling the voltage during the test process. A digitalized display screen which records and show the heating temperature of the Kanthal wire which is used for cutting. It has a uniquely constructed bottle neck holder for the tight holding of the PET container so that the cutting process does not interfere. The Kanthal wire has a faster heating rate and at once ready for the cutting process. Purchase the Hot Wire Bottle Cutter in Pune and experience the ideal testing solutions.

Humidity Test Chambers in Pune

The combination of relative humidity and increasing temperature may lead to damaging of coatings applied on the material, plastic parts, etc. Such conditions often interact with the outermost coating and start eating it up leading to damaging the protective layer completely. This in return exposes the prone material to extreme corrosive conditions. Hence, it is very much vital that protective coatings or materials which can easily get impacted by humid conditions must be tested before its production and supply in the market. The Humidity test chambers are used for inspecting specimen behaviour under extreme humidity and elevating the temperature. The cabinet is equipped with digitalized temperature and humidity programming operation. The chamber has a fast speed rapid air circulation fan for distributing of the test conditions uniformly. The circulating fan is made by German imported parts and is specially constructed as per global test standards. The cabinet complies with ASTM D1776 and ASTM D1776M-15 test standards. The temperature recording is performed using the latest technology PT – 100 sensor fitted in the chamber. Get Humidity Test Chambers in Pune for having the best humid test conditions in your quality lab.

Grammage Checking Kit in Pune