Testing Instruments in Srilanka

Conditioning Chamber

The Conditioning Chamber is best used for testing the materials under different environmental conditions. The device aids in determining the actual effect of different environmental extremes over physical and chemical properties of a material. The quality and efficiency of electronic appliances, rubber, textiles, etc. are tested by creating a temperature required. The instrument removes the moisture level from the testing material and is very useful for testing the quality of automobile parts, rubbers, plastics, and semiconductor devices.

Presto manufactures the efficient, reliable, compact conditioning chamber for the ease of the end users and ergonomics. The double wall structure is filled with the glass wool insulation that prevents maximum heat loss. The two adjustable perforated shelved are used to place the testing sample, where a low-pressure boiler generates steam to maintain chamber humidification. The chamber has circulation fan for uniform distribution of humidity and temperature. The stainless steel is used to make the inner and outer chambers as needed.

The machine is effective to condition textile samples due to quick humidity equilibration time. To alert, an electronic digital controller is provided inside machine that alarms for high temperatures. The machine removes the moisture level from a testing sample with effective temperature controls. The device is equipped with digital controllers, user-friendly, convenient to use, and compact to handle.

Salt Spray Chamber (Corrosion Tester) - Patent No. 244580

How Does a Salt Spray Chamber Perform Corrosion Testing?

The SST chamber stands out as the most dependable equipment for evaluating the corrosion resistance of surface coatings when subjected to a salt-laden environment. This high quality salt spray test machine is specifically crafted to assess the ability of components to resist rust and corrosion caused by atmospheric conditions. Offering unparalleled flexibility, the salt spray testing machine enables the simulation of real-life weathering conditions.

Users can easily adjust the test temperature within the chamber, ranging from ambient to +40°C, thanks to the user-friendly PID controller system. The salt fog test chamber boasts an HMI-based touch screen, serving as a powerful tool to facilitate the analysis of corrosion resistance across a diverse range of sample types. To enhance accuracy, a specialized zero corrosion PT 100 sensor is integrated into the apparatus. salt spray testing chamber makes it easy for the manufacturers to perform accurate salt spray test procedure.

Featuring a triple-walled design with glass wool insulation, the salt spray chamber ensures precise and reliable results, meeting international testing standards. Incorporating cutting-edge technology, it includes an Air Regulator that effectively manages air flow, ranging from 0 to 30 psi.

The Salt Spray Tester is designed as per various international Testing Standards which includes, ASTM B 117 and JIS Z 2371. Other than these features like Automated Air Purging and Online Fog Collection makes it easy for the user to perform an error free test.

In the metal industry, it is important for packaging product manufacturers to conduct a salt spray test on the materials in order to test the durability of their products against corrosion. With the use of the salt spray corrosion test chamber for Paint, Coatings & plating part manufacturers can easily detect the corrosion-resistant properties of the materials. It complies to ASTM B117 & JIS Z 2371 besides other standards. Users can easily select different types of dimensions of chamber available in this lab testing instrument is a leading manufacturer of salt spray chambers and offers this high-quality fog test chamber equipped with highly advanced features.

This salt spray test chamber will stimulate the atmospheric conditions for the products to test under different test conditions. This standardized SST Chamber will easily assess the behavior of the materials and ensure that accurate products will be delivered to the customers. This lab testing equipment also supports an Ethernet communication protocol that allows the users to connect devices utilizing LAN or an internet network. You can get the best salt spray chamber price when you purchase this lab testing instrument.

.png)

Crush /RCT/ECT /FCT Digital Model

Benefits of Edge Crush tester

The Edge Crush Tester – Digital (ECT) demonstrates robustness suitable for any paper and packaging production firm. It serves as the perfect testing instrument for industries such as paper making, packaging, quality inspection departments, and more. This digital ECT tester is valuable for assessing the potential compression strength of corrugated and solid fiberboard boxes by testing the paper and paperboard materials utilized in their production.

Edge Crush Tester / Ring Crush Tester / Flat Crush Tester is used for accurate testing of paper, paper-board, solid fiber-board & corrugated board for ECT test and its components. The Edge Crush tester can also be used for performing compression test on all small packages.

The higher ECT value determined by the ECT tester depicts the rigidity of the CFB box. Hence, it may be used to compare the quality of the CFB board. It is also possible to determine the compression strength of the box (CFB) by using ECT tester with McKee’s formula i.e.Compression strength = k. ECT x T x Z

Where K= Constant

ECT = edge crush test value

T=Thickness of CFB board (wall thickness)

Z= Perimeter of the box i.e. (2 L + 2 W)

Testing the edge-wise compression strength of corrugated boxes or cardboards is important in determining whether the materials will be strong enough to withstand the rigors of shipping or not. Thus, to make it easy for the paper and packaging product manufacturers to conduct the edge-wise compression strength on materials, this high-quality edge crush tester has been designed by the experts at best price in Presto.

This digital model of Crush /RCT/ECT /FCT model is for a simple and accurate read-out on a digital display. It comes with electronic force measurement for the load and the key locks embedded in this lab testing instrument will help the users to prevent accidental or unauthorized resetting.

The microprocessor-based display has also been embedded for accurate testing results. With its strong gripping clamps, bright LED display, and other advanced features, one can easily test the edge-wise compression strength of the materials. It comes with an in-built calibration facility, users can get accurate testing results every time they conduct the test.

Purchase an Edge Crush Tester directly from Presto, the trusted manufacturer at competitive prices. As a leading supplier, we provide reliable testing equipment to guarantee packaging strength.

Bottle Burst Tester - Touchscreen

Bottle Burst Tester is a consistent tool used to perform Bottle burst test on PET bottles with minimum pressure and check the volume expansion of test samples. The testing instrument Bottle Burst Tester - Digital is used to measure the Burst Strength of PET bottles when subject to pressurized air. It measures the volumetric expansion of PET bottle under pressure conditions to rupture or burst the bottle.

PET bottles are extensively utilized in various industries for bottling a diverse range of products, including carbonated drinks. However, a common issue encountered during the bottling of carbonated drinks is the potential for PET bottles to burst under high pressure or if they possess insufficient strength.For this the manufacturers of the PET bottles need to test the burst strength of the bottles using proper testing methods and testing instruments. Touchscreen Model of Bottle burst Tester is one of the best suited testing instruments that can be used for testing the strength of the bottles.

The bottle burst test is commenced by exerting a high amount of pressure in the bottles using highly pressurized air. The pressurized air replicated the pressure exerted on the bottles when a carbonated drink is filled inside them. The testing procedure helps in testing various aspects of a bottle such as expansion volume, burst strength and thickness of the walls of the PET bottles. Presto’s Bottle burst tester Touchscreen Model model is a highly sophisticated and accurate testing instrument that is used for testing the strength of the bottles widely in PET industries and bottling units.

Standard: ASTM C147-86(2015).

Cobb Sizing Tester

Cobb sizing tester is used for fast determination of the quantity of water absorbed by a paper or board in a given time. The Water absorptiveness (Cobb value) of a substance is defined as the mass of water absorbed in a specific time by a 1 sq. meter sample of paper, board or corrugated board, under standardized conditions.

Cobb Tester measures the amount of liquid penetration into a sheet of Paper, Cardboard or Corrugated Board. The Cobb sizing Tester consists of a cylindrical container clamped to a flat base with a flexible backing onto which the sample is placed. Cobb sizing tester provides a simple, standardized method for fast determination of the quantity of water absorbed by a paper or board at a given time.

Tensile Testing Machine Digital

How Does Tensile Testing Machine Work?

The Tensile Testing Machine is highly recommended for evaluating the tensile strength of products and materials. This Tensile Strength Tester is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw.

While the upper jaw is stationary, the lower one can be moved at a designated fixed speed with the help of a motor. The test specimen is held between the two jaws in this universal tensile testing machine. The lower jaw is gradually made to move to evaluate the tensile strength of the sample.

The motor is equipped with a gear Box and a lead screw arrangement. The tensile machine also incorporates a special sensor, connected with a load cell. The sensor is capable of judging the load exerted on the stationary jaw and directly indicating the reading in kgs (in digital format). If you are looking for high quality tensile testing machine India, then you can easily consult with our technical team. We offer the best tensile testing machine price and ensure that quality materials will be delivered to the customers.

There are special case hardened lead screws which ensure stability and durability. It incorporates a standard branded motor and CE standard electrical wiring. The completely modular construction of the Tensile Testing Machine ensures trouble free maintenance and easy operation.

The Tensile Test machine stands out as a robust and stable apparatus, constructed from durable heavy mild steel. This Universal Tensile Machine has strength and superior quality are ensured through integrated safety features, including overload and overtravel protection mechanisms.

Finished in a sophisticated Autumn Gray & Blue combination, the tensile compression tester further boasts bright chrome/zinc plating to enhance its resistance to corrosion.

The tensile strength testing machine has been Included with the instrument are essential components such as an Instruction Manual, Electrical Wiring Diagram, and a Calibration Certificate traceable to NABL-approved Labs. This comprehensive package ensures users have the necessary documentation and guidance for effective and accurate tensile testing procedures.

The tensile strength test conducted with the help of the tensile strength tester will help the manufacturers to assess the maximum load a material can withstand without getting deformed. By using tensile testing machine manufacturers will ensure the tensile properties of the materials and ensure that quality products will be delivered to the customers. is a leading tensile tester manufacturer and offers the best tensile tester price to our clients.

The digital model of this high-quality testing equipment comes with an advanced load sensor with linearity feature and repeatability to conduct the tensile strength test on the materials with ease. Besides this, we have designed this tensile tester in such a way that it can easily be transported without getting damaged. The safety limit switches have been embedded in this testing machine for over-travel safety.

With its bright LED display, users can accurately view the testing results and ensure that quality materials are delivered. It comes with specially designed gripper jaws for holding fragile samples. Users can easily customize this tensile testing machine according to their needs and requirements.

tensile strength test machine is one of the widely used laboratory testing instruments in different industries including paper and packaging, paint and coating, construction, automobile, and much more. Users can accurately and easily use this tensile test universal testing machine to determine the quality of their products against tensile forces. If you want to know about tensile strength tester price then you can easily contact us.

Buy a UTM Machine from Presto Group, the leading manufacturer of material testing equipment. Get the best price from a top supplier and ensure precise testing for your materials.

Hot Wire Bottle Cutter NXG

Presto’s Hot Wire Bottle Cutter is a widely used instrument in PET bottle industries. PET bottles are mainly used for packaging of various products such as carbonated drinks, food items and so forth. They are also used for packaging of chemical. The shape and size of the bottles is important for the better safety of the products that are packaged in the bottles. For the best shape and size, it is important to test the weight of every section of the PET bottles individually. This process is called the section weight analysis. For accurate section weight analysis, the individual sections of the PET bottles need to be cut properly and precisely without causing any deformation in the shape of the bottle. The Hot wire Bottle cutter helps in this testing procedure of the PET bottles.

The Presto’s Hot Wire Bottle cutter NXG is designed to easily cut the individual sections of the PET bottles. The capacity of the bottles that can be cut using the instrument ranges from 200 ml to 2000 ml. the maximum diameter of the bottles that can be cut with the hot wire bottle cutter is 110 mm. Each section of the bottles is cut in exact dimensions and not deformation occurs in the shape and size of the bottles during the cutting. After accurate cutting of the sections, each section is weighed on a digital balance for accurate measurement of the weight of the sections. This helps in controlling the manufacturing process for better quality assurance and quality control.

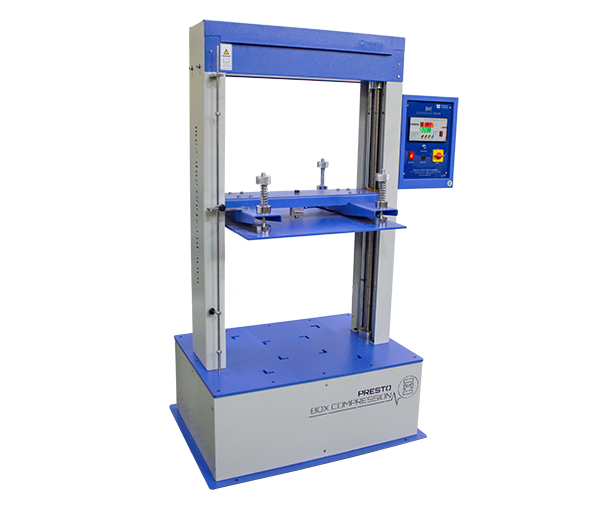

Box Compression Tester Digital

How does Box Compression Tester Work?

Box Compression Tester is a lab testing instrument designed for measuring the ability of corrugated boxes to resist compression to make sure that their compressive strength is strong enough to avoid any sort of deformation or breakage while stacking during storage or transportation. The corrugated box is compressed or pressed by a platform moving downwards from the top simulating the pressure a box will withstand while getting stacked.

The lab testing instrument is manufactured to measure the strength and performance of a corrugated box and ensure the effects from other mediums like board, closures & interior partitions are not adverse enough to break or deform the box. Group has manufactured the Box Compression Tester to assist the paper & packaging industry as per International Standards. The hassle-free operations and ergonomic design make this instrument highly valuable.

Box Compression Tester is used to measure the box compression strength (BCT), shape change and stacking capability of cartons, beehive crates, paper tanks, paper cases etc. Box Compression Tester is designed to evaluate compression strength of the corrugated box and the load range selected to completely collapse as peak load or may be with a pre-determined load for a given period to evaluate stacking load. Compression Strength Test also serves as a useful index of over all quality of the material and workmanship of the box.

The Compression strength is determined by placing the box on a flat platform and pressing it downwards from the top with the help of a motorized arrangement. Box Compression Tester is designed to quantify box or container performance so that the effect of various board mediums, closures, and interior partitions can be plainly compared by means of Load & bend analysis. This high-quality lab testing instrument has been made in accordance with industry standards that make it easy for the manufacturers to conduct the box compression test on the materials with ease.

This compression strength tester consists of a Microprocessor-based display that let the users view highly accurate testing results under uniform compression force. It comes with a strong base plate with a rugged structure and an optional printer facility. Users can easily operate this lab testing instrument with its feather touch controls. This testing instrument is also available in a computerized model also with various platform sizes and load cell capacity. Thus, with the use of this high-quality lab testing instrument, users can easily conduct box compression tests and ensure that their product will not get deformed or compressed while stacking. Our box compression tester Price in India is very good & reasonable according to our product quality.

Buy a Box Compression Tester from Presto, the top manufacturer in the industry. With over 41+ Years of Experience we are determined to ensure your packaging meets global standards.

Wall Thickness Gauge

Benefits of Wall Thickness Gauge

Magnamike is a high-quality product by Olympus. It is the best device to perform wall thickness gauge testing. The instrument provided a non-destructive method of testing the wall thickness of the PET bottles. Presto Stantest is an authorized dealer of the device. The device is used to measure the thickness of non-ferrous material that ranges from PET, plastics, preforms, plastic bottles, water tanks glass bottles, aluminum, etc. The wall thickness gauge offers reliable and accurate test results.

The best testing device which is used to perform bottle thickness measurement is Magnamike 8600 – wall thickness gauge. The instrument is widely used to test the quality of non-ferrous material like Preforms, glass, water tanks, aluminum, foam, PET, etc. The testing instrument works on the principle of Hall Effect technology. It works on a very simple magnetic procedure that makes a simple and repeatable measurement of non-ferrous materials. The device is provided with the digitally colored display that clearly shows the result of thickness measurement on the screen.

Presto offers the best quality of wall thickness gauge testing instrument i.e. Magnamike 8600. The instrument works on the basis of Hall Effect Technology. To perform the test efficiently, it is necessary to access both sides of the container. The ball is placed inside the bottle, and the magnetic probe is placed outside. The sensor inside the probe measures the distance between the ball and the probe tip which helps to measure the thickness of the bottles accurately and efficiently. The wall thickness gauge is used to measure the thickness of plastic bottles, glass containers, aluminum beverage cans, foam, paper glass, HDPE containers.

Applications:-

- Thickness of Plastic Bottles & Packaging for Pharmaceutical and Medical

- Measuring Thickness of Glass Containers & Scientific Glass.

- Measuring Thickness of Aluminium Beverage cans.

- Measuring Thickness of Paper Glass

- Measuring Thickness of Foam

- Measuring Thickness of HDPE containers

Purchase a Magna Mike thickness tester from Presto, the leading supplier of Bottle Wall thickness measurement system. Buy now at the best price from a trusted supplier.

Melt Flow Index Tester - Deluxe

Benefits of Melt Flow Index Tester

The Presto Melt Flow Index tester is utilized for assessing the flow characteristics of molten plastics or resins. The Melt Flow Index of thermoplastic materials is defined as the rate of flow (expressed in grams per ten minutes) of molten resin extrudates through a jet of specific length and diameter. The test is conducted under specified conditions of temperature, load, and piston position in a cylindrical cavity within a heated metallic tube barrel. This MFI machine is precisely adheres to all standard temperature and pressure terms in accordance with ASTM D 1238-1992, ISO 1133, IS 2267-1972, IS 2530-1963, IS 10810-1984.

Equipped with a Microprocessor-based PID Temperature controller, this MFI tester features a temperature range from ambient to 400°C, a resolution of 0.1°C, and an accuracy of ± 0.1°C. The instrument includes a digital presettable timer with a range of up to 59 minutes and 59 seconds, along with a buzzer output. The automatic sample cutting provision ensures accuracy and smooth operation.

Constructed on a sturdy metal base plate for stability during operation, the Presto MFI testing machine boasts an Autumn Gray & Blue combination painting finish. Additionally, a bright chrome/zinc plating enhances corrosion resistance. The instrument is supplied with an instruction manual, Electrical Wiring Diagram, and a Calibration Certificate traceable to NABL approved Labs. If you want to buy MFI tester then you can easily contact us.

Purchase a Melt Flow Index Tester from Presto Group, the trusted manufacturer of precision plastic testing equipment. Get the best price from a reliable supplier today.

Scuff Tester- Model No.PSR - 292 Patent No. 336716

Benefits of Scuff Resistance Tester

Scuffing refers to the process in whichtwo materials rub against each other. A Scuff Tester is employed to assess the rub resistance, which measures the damage incurred through rubbing, particularly on labels and general printed materials.

The Scuff Resistance Tester facilitates the rubbing of two printed surfaces against each other, facing each other in the same plane, at a consistent speed and under constant rubbing pressure. Widely utilized in the Paper & Packaging industries, this tester aids in evaluating color transfer from printed or coated surfaces during rubbing tests. It is designed and produced according to ASTM Standard and measures the number of double strokes required to cause Fuzz (distortion of appearence) and Peel (actual rupture of the surface).

With the help of Scuff Tester, the manufacturers can easily ensure the best quality of printed products to the clients.

By using this scuff resistance testing instrument designed by the experts at, check the print quality of the materials and ensure accuracy every time you ship your products to the customers. This lab testing instrument comes with a motorized weight arrangement on the plunger for noise-free working. It will firmly hold the testing specimen by its circular clips/clamps and comes with a motorized geared system for scuff movement.

This highly accurate lab testing instrument will easily measure the rub-proofness of materials, printed paper, carton packages, and board. Besides this, users will get accurate and precise testing results under a uniform load with the use of this high-quality lab testing instrument. Its user-friendly electronic controls and ergonomically designed features make it easy for paper and packaging product manufacturers to conduct scuff resistance tests on the materials.

Presto is a leading scuff tester manufacturer and provides the best scuff tester price to clients. It comes with a motorized weight arrangement on the plunger for noise-free working. With its user-friendly electronic controls and ergonomically designed feature, users can accurately conduct scuff resistance tests on the materials.

Purchase a Scuff Tester from Presto Group, the leading manufacturer of print durability testing equipment. Get the best price and top performance from a trusted supplier today.

Vacuum Leak Tester Digital

This high quality vacuum leakage tester has been compiled with national as well as international standards including ASTM F 2338-09(2013), ASTM D 4991-07(2015), and ASTM D6653, ensuring accurate and reliable lab testing results.

How it works:

The leak detector and seal integrity testing unit is a high-quality machine that consists of a clear acrylic vacuum chamber and system, a control valve, and an indicator gauge. Packages to be tested are simply placed in the clear acrylic vacuum tank, the lid is closed and Vacuum leak tester engaged. You can then choose which testing method to use based on your company’s standards and requirements. A complete test can be accomplished in just a matter of seconds with immediate results!

Testing Standards (Methods):

ASTM F 2338-09(2013) – Non-destructive detection of leaks in packages by vacuum decay method.

The ASTM D6653 is the standardized testing equipment that accurately determine the effect of high altitude on packaging systems.

ASTM D 4991-07(2015) – Destructive Leak integrity test by vacuum method for empty rigid containers. Leaks are detected under differential pressure conditions.

Testing Specimen Types:

Different types of testing specimen can easily be tested with the help of this testing equipment includes rigid trays, vacuum packs, themoform packages, sachets, flow wraps, form fill seal and reclosable packages.

Buy a Vacuum Leak Tester from Presto, the industry-leading manufacturer. Ensure airtight packaging with our equipment at the best price from a reliable supplier.

Laboratory Heat Sealer - Prima Model - PLHS-22 (150 mm)

Benefits of Heat Sealer Machine

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films, plastic films such as PP, PE used in packaging different food products such as milk powder, instant noodle, food, washing powder, and drugs.

The Presto (Pneumatic Model laboratory) Heat Sealer is widely used in the plastic industry. The temperature of the Presto Heat sealer is also adjustable. The instrument has been provided with Digital Display and is Microprocessor based.

Both the upper and lower jaws of the Presto Heat sealer are heated separately with separate temperature sensors and controllers. Thus, it is possible to maintain both jaws at different temperatures. It is even possible to switch off one heater, while keeping the other on.

The Presto lab heat sealer is widely used in the packaging industry to seal flexible packaging products and other thermoplastic materials using heat and pressure. This high-quality heat seal testing instrument comes with a microprocessor-based display for accurate test results. This lab heat sealer comes with a sealing temperature working range of ambient to 230 degrees Celsius. Presto is a leading manufacturer of laboratory heat sealers and offers this testing equipment embedded with highly advanced features.

The Presto heat sealing equipment has been manufactured as per industrial standards that include ASTM F 2029. Besides this, it comes with a PID temperature controller for the highest level of control and repeatability. It comes with a digital preset timer and works on a guide rod mechanism for efficient control of sealing. With the use of this lab testing instrument, one can effectively test the seal strength of packaging films and ensure quality material will be delivered to the customers. This consistent and easy-to-use lab testing equipment will make the product more functional by determining its sealing strength. You can get more information like laboratory heat sealer price then you can easily consult with us.

Buy a Heat Seal Tester directly from the top manufacturer and trusted supplier, Presto Group. Secure competitive prices and ensure packaging integrity with our high-quality equipment.

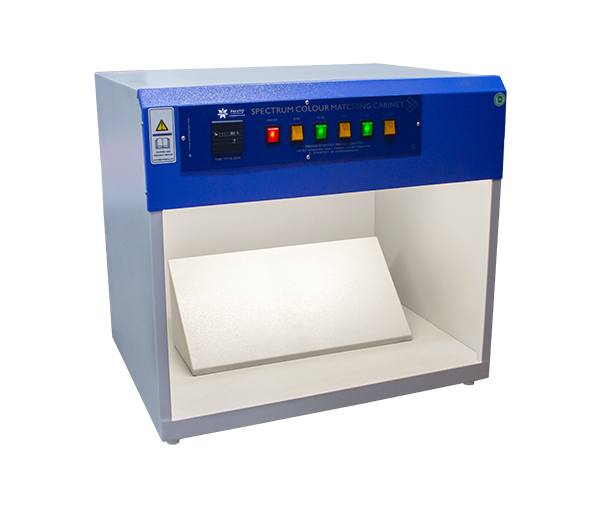

Colour Matching Cabinet - CMC - Asia

Benefits of Colour Matching Cabinet

The Presto Color Matching Cabinet Spectrum Asia II is one of the widely used lab testing instrument in the industries and laboratories where it is important to maintain the color consistency of the products. This color matching machine will provide accurate assessment of colors under standardized environment for evaluation and visual assessment of colors.

Metamerism is a phenomenon wherein the test samples appears to match under one light source but seem different when viewed under another light source. In such situations it is highly beneficial to use the Presto Color matching cabinet. The equipment is widely used in the paint and plating industry, besides textile & yarn, plastic, paper and other areas.

The Presto color matching cabinet – Spectrum Asia (Rocker Switch Control) provides faster, closer and accurate color matching solution. It has, thus, been the universally preferred choice for decades.

Presto has designed this color matching cabinet- CMC Asia that has been embedded with different light sources to test the quality of colors in a manufactured product. This will help you to maintain the quality and consistency of colors and make sure that you deliver Metamerism-free products to your customers.

With its standardized and controlled lighting conditions, one can easily ensure that high-quality products will be delivered to the customers with ease. This high-quality testing equipment has been made in accordance with industry standards that include ISO 3664, BS 950, ASTM D 1729, and DIN 6173. The angle of the viewing booth is 45 degrees so that the users can accurately view the color difference in the product with ease. We at Presto are leading color-matching cabinet manufacturers and provide the best color-matching cabinet price.

With the expanding demand for accurate colored products in the market, we at Presto have designed this quality product to ensure that the right product will be delivered to the customers with ease. With its consistent testing environment, you will be able to test your products accurately and test any sort of color difference present in the product. This lab testing instrument is widely used in different industries and ensures that products will be tested for color accuracy.

Top Load Tester - Digital

Benefits of Top Load Tester

The Top Load Tester is a fully automatic motorized model that provides the compressive buckling load in digital format. Its digital display is not only aesthetically appealing but also sophisticated, offering easy readability. It comes with features like Auto Tare (ZERO) set facility and Peak Hold arrangement.

This advanced generation of the Top Load Tester is fully automatic and motorized, capable of providing digital readings for compressive buckling load. The load sensor can be calibrated in-house for accurate measurements. To ensure secure gripping without slipping, the bottle is placed between the inverted concave jaws. The operator can easily switch off the machine upon observing buckling in the PET bottle.

Designed specifically for determining the load-bearing capacity of PET containers under extreme top loads, the Top Load Tester accurately measures the maximum load a PET container can withstand without deformation or failure.

Top load tester is a reliable equipment which is used to evaluate the load-bearing capacity of containers. It is particularly useful for assessment of plastic containers, PET bottles and cans. It works on the principle of measuring the amount of force required to crush a container or cause it to deform. This parameter is crucial for evaluating the structural integrity and durability of plastic/packaging materials.

Widely used in the packaging industry, the Top Load Tester is specifically designed to ensure that containers can withstand the forces they encounter during shipping, handling, and storage. This test helps manufacturers in preventing product damage and preserving product quality.

Further, it is used to measure the buckling strength of PET bottles or plastic containers. Simulating real-life compressive load, TOP LOAD TESTER is useful in assessment of a PET bottle, since it gives an accurate measure of the stress experienced by it during storage or in transportation. Evaluating the capacity of a bottle/plastic specimen against vertical compressive load, using Top Load Tester further helps in quality control and quality assurance.

Applications:

• For compressive buckling load in digital format in PET bottle manufacturing plant

Buy a Top Load Tester directly from Presto Group, the industry-leading manufacturer. Enjoy competitive prices from a trusted supplier and ensure packaging strength with our accurate testing solutions.

Laboratory Hot Air Oven

Key Features and Benefits of Presto Hot Air Oven

The Hot Air Oven serves as a distinctive testing chamber crafted to identify alterations in the physical attributes of materials and gauge their actual operational lifespan under elevated temperatures.

The hot air oven principle is based on the forced air circulation and thermal convection, this oven conducts a range of tests, including heat deformation, compression set, and heat resistance crucial in the rubber and plastic industries. Equipped with an air circulating fan, the Hot Air Oven ensures efficient heating maintenance. We provide highly standardized hot air oven specifications that makes it easy for the users to conduct quality tests on the materials.

Presto Laboratory Hot Air Oven proves versatile in assessing the impact of elevated temperatures on diverse materials such as rubber, textiles, yarn, plastic, metal, and paper. As a result, it finds extensive application in testing heat resistance and heat deformation across industries like rubber, paper, textiles, yarn, and various other sectors. To know about the hot air oven price, you can contact with our team of experts.

The Presto Hot Air Oven is a reliable and time tested instrument. The exterior has been given an autumn gray and blue combination finish and the chrome/zinc plating ensures resistance to corrosion.

The Presto Laboratory Hot Air Oven comprises of a double walled chamber, wherein the inside wall is fabricated using heavy stainless steel and the outside wall is made of duly powder coated mild steel. Impartial mineral glass wool is incorporated within the walls to ensure that the chamber is well insulated. A special T/P action ensures that the temperature does not overshoot the designated level.

The instrument comes complete with an instruction manual, electric wiring diagram and a calibration certificate traceable to NABL approved labs.

Looking for the best hot air oven price? Prestro Group is widely regarded as the best manufacturer and supplier of hot air ovens, known for their top quality and durability. Order now for the best deal!

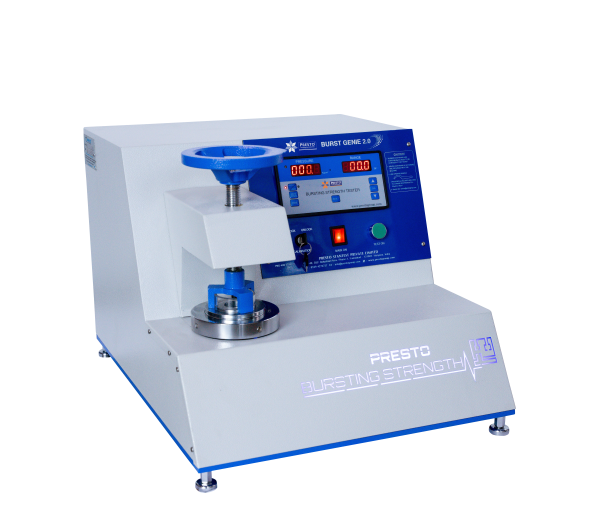

Bursting Strength Tester Genie 2.0

Working mechanism of Bursting Strength Tester Genie 2.0

The determination of the force required for the bursting or complete rupture of a material is conducted using a Digital Indicator. This bursting strength is a crucial parameter that sets the quality of the material in comparison to others. The Digital Bursting Strength Tester, offered by, operates by applying hydraulic pressure under a rubber diaphragm with a specified area onto the test sample. A bursting strength tester machine is versatile and can accurately assess the bursting strength of various materials such as paper, corrugated cardboard, carton boxes, cardboard, leather, cloth, or synthetic leather. The resulting bursting strength value is quantified in kg/cm².

Bursting Strength Tester Machine is specifically designed for measuring the bursting strength of paper and strong paperboard. The testing procedure involves preparing the specimen and securing it between two circular clamps. Using the geared handle provided, the specimen is tightened. The hydraulic pressure is incrementally applied by manipulating the handle until the specimen ruptures. The digital display then indicates the bursting strength of the test specimen in kg/cm². If you want to know more about hydraulic bursting strength tester like bursting test machine features or other related information, then you can easily contact us.

The pressure at which a film or sheet of plastic or paper will burst defines its bursting strength. A precise measure of the maximum pressure it can withstand, it is a parameter often used for evaluation of paper, plastic films & flexible packaging.

The pressure is applied on the sample at a right angle to the surface, using a bulging circular elastic neoprene diaphragm. Depending on the durability of the material and its tensile strength, Bursting Strength is expressed in pound per square inch (psi). It basically, translates into the resistance to breaking or damage, offered by the sample.

The manufacturer is able to analyse the strength of the package, as well as the quality of corrugated material. These attributes can be evaluated and graded based on its bursting strength.

Buy a Bursting Strength Tester from Presto, the industry’s top manufacturer of packaging strength equipment. Get competitive prices from a reliable supplier and ensure packaging durability.

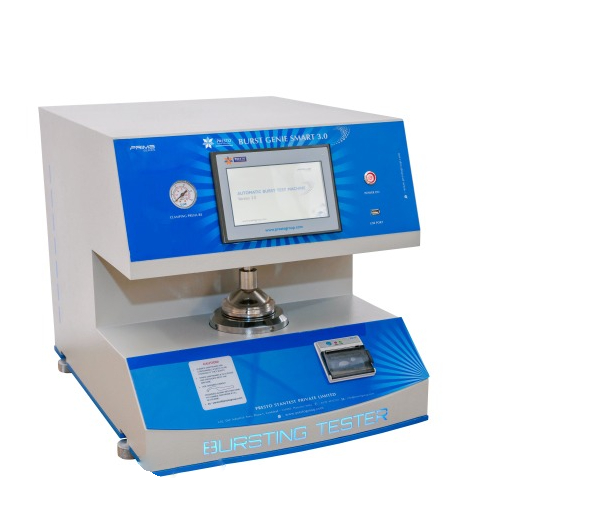

Bursting Strength Tester Genie Smart 3.0

Bursting Strength Tester is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene. With the help of a bursting strength tester, industries can ensure the best quality of products to their clients. Presto is one of the leading manufacturers of Bursting Strength tester.

Other models available of Bursting Strength Tester are: Digital Model, Pneumatic Model, Computerized Cum Digital Model with Manual Clamping and Computerized Cum Digital Model with Pneumatic Clamping.

The bursting strength of the sample is measured by applying the hydrostatic pressure required for producing rupture of the material, when pressure is applied at a controlled increasing rate through a rubber diaphragm. The value of the bursting strength will give an indication of the maximum weight that may be carried in the box. The quality of Corrugated Boxes is graded based on the value of their bursting strength. The Analogue Bursting Strength Tester is a testing instrument that offers highly reliable and accurate test results.

Polariscope Strain Viewer - Deluxe

Polariscope, a highly efficient strain viewer that helps the manufacturers in testing the quality and transparency of the products so that best quality assurance could be ensured to the customers. The working of the Polariscope is based on the principle that any change in refractive index is due to different strain distribution and this leads to lower transparency of the material. The testing instrument offered by Polariscope comes in variety of sizes and specifications according to the requirements of the clients

Photoelasticity is a significant phenomenon observed in PET, preforms, and glass products. It refers to the alteration in the material's refractive index due to non-uniform strain distribution. Photoelasticity poses a considerable challenge for manufacturers of PET and glass items as it represents a notable flaw in product quality.

Offers two models of Polariscope that are Polariscope Dx and Polariscope computerized. The instruments are manufactured with best quality of materials to provide an extended service life and accurate testing procedures. The testing instrument is provided protection from corrosion and rust with Zinc and chrome plating and has been given a smooth and attractive finish in grey and blue color. The instrument is also provided with an instruction manuals and a conformance certificate that can be traced to any of the NABL approved laboratories.

Purchase a Polariscope from Presto, the premier manufacturer of stress testing instruments. Get precision results at the best price from a certified supplier today.

.jpg)

TP110 Precision Color Measurement

The Farbung TP110 is a highly used and preferred color measurement instruments in many industries. There are several new features that are added to the product by the highly competent team of engineers and scientists of Presto Stantest. Precision Color Matching TP110 is a consistent tool useful for portable and high-quality color measurement. It works with a color sensor with multiple channels according to international standards.

Check The Difference Between Different Models Of Presto Stantest Products

Peel / Seal / Bond And Adhesion Strength Tester

Benefits of Peel/Seal/Bond and Adhesion Strength Tester

The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at a specified angle and speed. Compliant with ASTM standards, the Presto peel tester machine is particularly well-suited for applications in the plastic packaging industry.

Constructed on a sturdy metallic base plate with an Autumn Gray & Blue combination finish, the instrument boasts a corrosion-resistant touch thanks to its bright chrome/zinc plating.

The peel tester is provided with a comprehensive package including an Instruction Manual, Electrical Wiring Diagram, and a Calibration Certificate traceable to NABL approved Labs.

Designed by Presto's experienced professionals, this testing instrument ensures precise measurement of the peeling strength of materials. Presto, a prominent manufacturer in peel strength tester manufacturing, specializes in producing peel/seal/bond and adhesion strength testers.

This high-quality lab testing instrument consists of a microprocessor-based display for accurate testing results. This peel-strength tester has been made in accordance with industrial standards that ensure users get highly accurate testing results. Besides this, the Presto peel strength tester comes with powder coated corrosion-resistant body that facilitates users to use this testing instrument for a longer period of time.

This lab testing instrument is easy to operate. Just place the specimen between the upper and lower grip and tighten the grip firmly and commence the test. Whenever the users can operate this testing machine then it is important for the manufacturers to place the specimen accurately. Users will get highly accurate test results under elongation force. Besides this, the Presto peel strength tester comes with feather touch controls that make it easy for the manufacturers to conduct the peel strength of adhesives with ease.

Buy a Peel Strength Tester from Presto, the industry-leading manufacturer at the best price. We are a reliable supplier providing accurate and durable testing equipment for packaging quality control.

.png)

Dart Impact Tester- Aero Series

Dart Impact Tester is a consistent tool for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder. PRESTO Drat Impact Tester is manufactured under Test Standard IS 2508: 1984( R2003), ASTM D1709-16A

Testing Instruments in Srilanka

Product testing is an essential step in ensuring that the quality of products will be delivered to the customers. But how can you make sure your testing process is as efficient and effective as possible? This can be done with the use of the right lab testing instruments. If you are looking for high-quality lab testing instruments in Sri Lanka then you can go with Presto Quality Testing Instruments. We at Presto offer high-quality lab testing equipment for different industries so that the manufacturers will be able to deliver quality products to the customers.

These quality testing instruments are essential for ensuring the quality of your products. By testing your products, you can identify and fix any defects before they reach your customers. This can save your time and money in the long run, as well as improve customer satisfaction.

Benefits of using quality lab testing instrument

Testing products quickly and efficiently can save you time and money in the long run. By testing products early on, you can identify any potential issues and address them before they become costly problems.

Additionally, testing can help to improve the quality of your products by ensuring that they meet customer expectations.

There are a number of benefits to testing products with the help of Presto Quality Testing Instruments:

By identifying potential problems early on, you can avoid costly delays. Thus, using lab testing equipment is efficient in testing the quality of products.

Testing can help ensure that your products meet customer expectations and are free of defects.

By identifying potential risks early on, you can take steps to mitigate them before they cause serious damage.

The lab testing instruments will not only help the users to ensure that the manufacturers reduce zero product rejections.

These are the benefits of testing products efficiently with the help of lab testing instruments. You can easily go with Presto Quality Testing Instruments. You can also conduct a free sample testing session regarding this quality testing instrument by giving us a call at +91 9210903903 or emailing us at info@prestogroup.com. Our team of technical experts will consult you regarding all your needs and queries.