medical-product-testing-instruments

Tensile Testing Machine Digital

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

Peel / Seal / Bond And Adhesion Strength Tester

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

Laboratory Heat Sealer - Prima Model - PLHS-22 (150 mm)

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

Laboratory Hot Air Oven

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

Top Load Tester- Prima (Touch Screen)

The new generation Top Load Tester - Prima Series for PET bottles and jars is a fully automatic motorized device that helps to generate compressive buckling load on the products. The instrument offers compressive buckling load on Human Machine Interface based Touchscreen display.

Drop Tester - Manually Operated

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

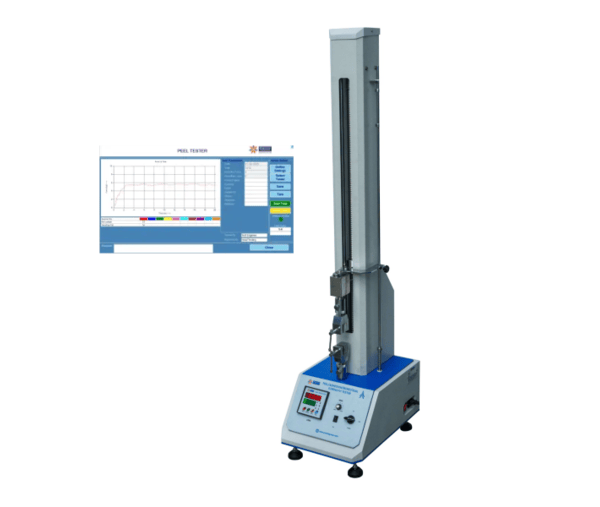

Peel / Seal / Bond and Adhesion Tester Digital Cum Computerised Model

Peel Adhesion/Bond/Seal Strength Tester is a consistent tool to quantify the permanence of adhesion or peel ability of a self-adhesive pressure sensitive materials. Used for checking the Peel, Adhesion, Bond, Seal Strength testing for Plastic Films and Foil.

Top Load Tester - Digital

The Top Load Tester gives the compressive buckling load in digital format. This is a fully automatic motorized model. The Digital display of the Digital Top Load Tester is aesthetically appealing and sophisticated.

It has the capability of measuring the maximum load a container can withstand without deforming when the force is applied from the top.

A Top Load Tester plays a major role in testing strength of items like bottles, containers, jars or packaging materials. It will help you avoid transit issue. You will be able to restrain deformation and defects while storage, shipping and transportation. A Top load tester is widely accepted in various industries like bottling manufacturing, filling and beverage etc. It is a proven method to avoid rejections and leave a perfect impression on your customers.

Registered Design Patent No. 279112

Laboratory Heat Sealer in Bangalore

Heat Sealing Machine is utilized in packaging industry to inspect the quality of sealing agents at high temperature. The machine is equipped with two layers of sealing jaws that can be separately heated and the temperature controlled for sealing. Get the ultimate testing solution with Laboratory Heat Sealer in Bangalore, Karnataka and all across the nation.

Top Load Tester in Pune

Top load testing machine is widely used in Plastic bottle vertical in order to determine the resistance strength of bottle under increasing vertical compressive load. The equipment is a digital version model and can precisely imitate the compression load utilizing straight inverted plates. The test aftereffects can be visually checked on the specimen post-test. Get the best test solution for PET bottles with Top Load Tester in Pune, Maharashtra. We also cater to international countries with testing instruments.

Laboratory Heat Sealer in Haridwar

The heat sealing machine is used to check the heat seal performance of packaging plastic films. The machine can simulate the similar sealing conditions found in the production process to check the seal strength. Now Purchase Laboratory Heat Sealer in Haridwar, Uttarakhand and implement positive changes in the sealing process.

Humidity/Conditioning Chamber Deluxe Model

Humidity/Conditioning Chamber is a unique test cabinet designed to create temperature and relative humidity inside the chamber to detect the change in the physical characteristics of material and to ascertain the actual working life of testing device. PRESTO humidity chamber is designed as per standards ASTM D1776, ASTM D1776M-15.

medical-product-testing-instruments