injection-molding-testing-equipments

.jpg)

TP310 Portable Color Measurement

TP310 is a prominent color measurement instruments used in many mainstream industries which have been designed and manufactured by competent engineers and scientists of Presto Stantest. The instrument has many advantages of other international standard color measurement instruments.

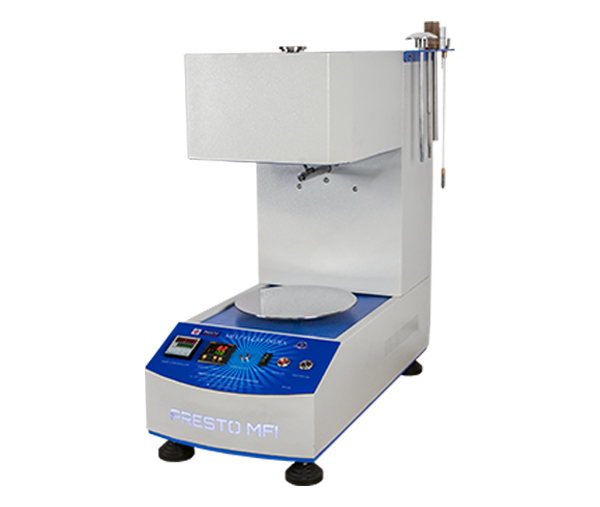

Melt Flow Index Tester - Deluxe

Presto Melt Flow Index Tester is used for evaluating the flow properties of molten plastics or resins. The Melt flow Index of thermoplastic materials is defined as the rate of flow (in grams per ten minutes) of extrudates of molten resins through a jet of a particular length and diameter.

Melt Flow Index Tester - Next Generation

The Presto Melt Flow Index Tester - NXG Model is a reliable instrument used for evaluating and analyzing the flow properties of molten plastics or resins. The determination of the melt flow index of plastic materials is an important parameter in the evaluation of its quality.

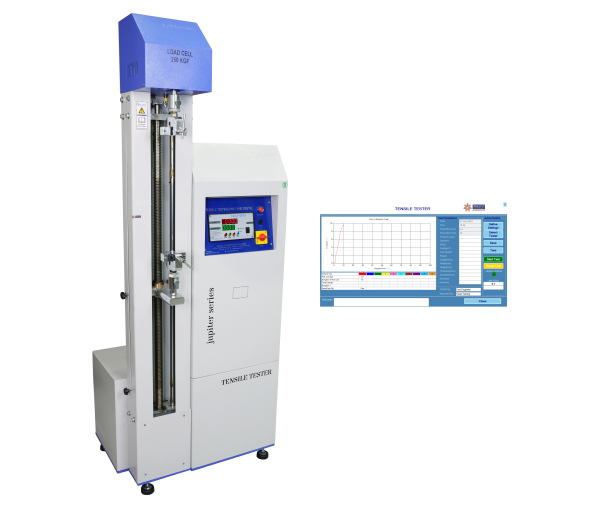

Tensile Testing Machine Digital

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

Digital Tensile Testing Machine Cap 2500KG

The Presto Tensile Testing Machine is based on the Constant Rate of Traverse (CRT) principle. During the test, the sample is held between two jaws. The upper jaw is stationary, while the lower jaw is made to move at a designated fixed speed with the help of a motor.

Wall Thickness Gauge

Magnamike, manufactured by Olympus, is a premium-quality device renowned for its excellence in conducting wall thickness gauge testing. Offering a non-destructive testing method, this instrument is ideal for measuring the wall thickness of PET bottles. Presto Stantest serves as an authorized dealer for this device.

In stock

Vibration Table

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

Laboratory Hot Air Oven

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

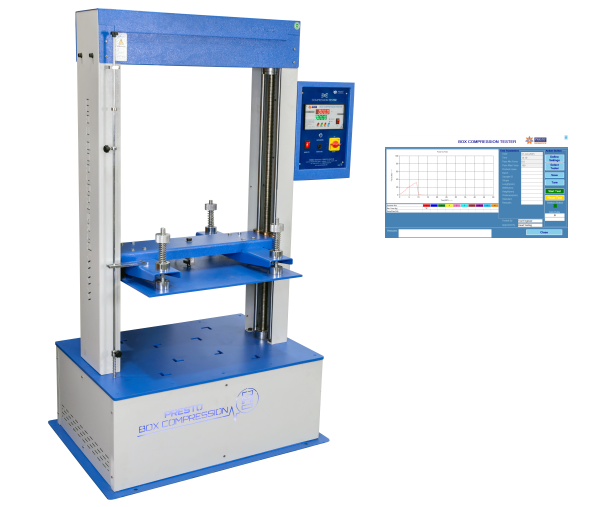

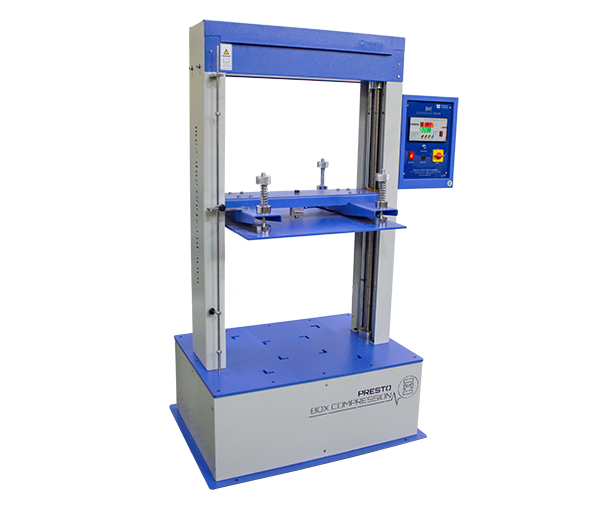

Box Compression Tester Digital

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Cardboard boxes are commonly stacked one on top of the other, during warehousing and storage. So, to ensure that they do not collapse during this, it is necessary to measure their box compression strength. It is based on the principle of measuring the maximum load that the material can withstand without breaking. This process is performed by applying a gradually increasing compression force to a sample until it fails using Box Compression Tester.

Using the equipment, a force-deformation curve can be obtained. This curve helps us evaluate the resistance of a package. It is a reliable equipment that provides accurate information regarding the compressive strength and durability of the package. It enables manufacturers to choose a more resistant packaging and to ensure the contents of the package don’t get damaged during stacking or transit.

Thus, corrugated boxes/cartons/paper packaging can be tested using Box Compression tester. It is widely used to determine compressive resistance, deformation and stacking capability of cartons and corrugated boxes.

Registered Design Patent No. 279106

In stock

Top Load Tester- Prima (Touch Screen)

The new generation Top Load Tester - Prima Series for PET bottles and jars is a fully automatic motorized device that helps to generate compressive buckling load on the products. The instrument offers compressive buckling load on Human Machine Interface based Touchscreen display.

Drop Tester - Manually Operated

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

Tensile Testing Machine Digital Cum Computerised Win Test Model

Tensile strength is the stress at which a material breaks or permanently deforms. PRESTO Digital Tensile Tester is a state of the art, highly versatile equipment for checking the breaking strength of packaging related raw materials and finished products.

Top Load Tester - Digital

The Top Load Tester gives the compressive buckling load in digital format. This is a fully automatic motorized model. The Digital display of the Digital Top Load Tester is aesthetically appealing and sophisticated.

It has the capability of measuring the maximum load a container can withstand without deforming when the force is applied from the top.

A Top Load Tester plays a major role in testing strength of items like bottles, containers, jars or packaging materials. It will help you avoid transit issue. You will be able to restrain deformation and defects while storage, shipping and transportation. A Top load tester is widely accepted in various industries like bottling manufacturing, filling and beverage etc. It is a proven method to avoid rejections and leave a perfect impression on your customers.

Registered Design Patent No. 279112

Vacuum Leak Tester Digital

The Digital Eco Vacuum Leak Tester is a cost-effective and efficient testing solution designed to enhance the quality control processes in your packaging applications. Crafted with exceptional precision, this laboratory testing equipment is tailor-made for the accurate detection of leaks in a diverse range of packaging materials. Proficient in examining a wide array of items such as foiled cups, gels, grains, cereal, bakery products, confectionery items, frozen foods, cheese, medical supplies, and pharmaceutical products, the Digital Eco Vacuum Leak Tester is your go-to solution. Whether you need a vacuum leakage tester for testing your food packets against vacuum leakage or you want to preserve the integrity of your packaging then you must go for our vacuum testing machine.

Box Compression Strength Testing Machine

Presto designs and manufactures the box compression strength testing machine to test the quality of the corrugated boxes (used in most packaging industries to pack food item or other items), paper boards, cartons, paper cases, beehive crates and many more.

l 600.png)

Vacuum Leak Tester - Prima (Dry & Wet)

Presto Vacuum leak detection system is now available in Prima series. With HMI Touch Screen Display and fully automatic controls, one can ensure accuracy with repeatability and take data acquisition for the various tests. The Vacuum Tank is specially designed to conduct leak integrity testing of large sized packages in any of the testing mediums.

Box Compression Tester in Bangalore

Corrugated Box Compression tester is utilized to imitate the compressive load which is experience while warehouse storage or during transport. At this stage, the corrugated or carton boxes are often kept each one on the other box. Now you can have Box Compression Tester in Bangalore, Karnataka with unlimited access to expert testing solutions.

Top Load Tester in Pune

Top load testing machine is widely used in Plastic bottle vertical in order to determine the resistance strength of bottle under increasing vertical compressive load. The equipment is a digital version model and can precisely imitate the compression load utilizing straight inverted plates. The test aftereffects can be visually checked on the specimen post-test. Get the best test solution for PET bottles with Top Load Tester in Pune, Maharashtra. We also cater to international countries with testing instruments.

Melt Flow Index - MFR Model (Method - A & B)

The new-design MFR Model can quickly extrude the flow rate of molten resins utilizing the advanced setup of load, piston, and a metallic barrel. The specimen, majorly in granule form is put inside the barrel and the piston is inserted. Loads, as per requirement are placed on the piston and the parameters are then selected from the touchscreen display.

Melt Flow Index - Junior

The melt flow rate of the polymers is one of the essential properties of the materials that will help the manufacturers in determining the rate at which it flows. This property of the material is important as it provides the necessary data on the mass flow rate of the polymer. Thus, to test the melt flow properties of the materials, we at Presto have recently designed a high-quality Melt Flow Index Junior model.

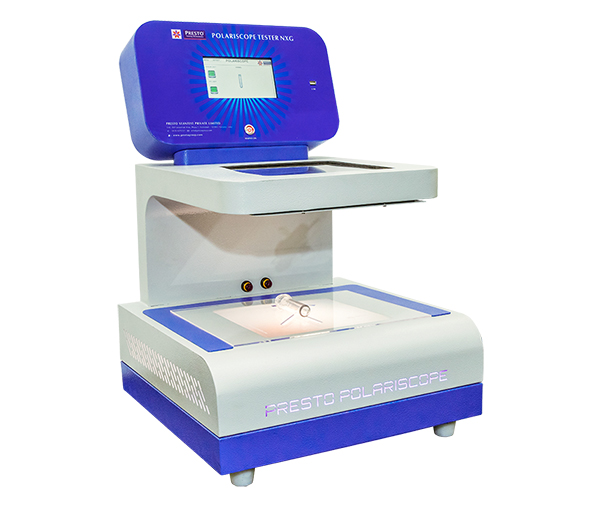

Polariscope Strain Viewer – NXG

Different defects like cracks and strains present in PET & preform products may affect their quality. Testing these defects will help the manufacturers to gain confidence in their product quality. Presto has designed a high-quality lab testing instrument known as Polariscope Strain Viewer-NXG.

injection-molding-testing-equipments

.jpg)