corrugated-testing-instruments

Tensile Testing Machine Digital

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

Vibration Table

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

Laboratory Hot Air Oven

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

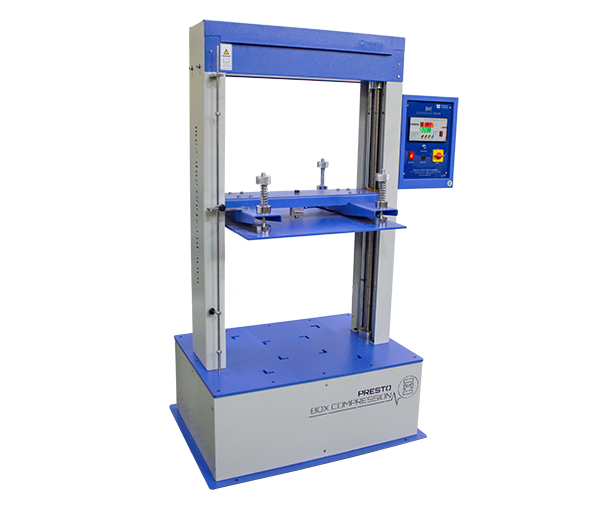

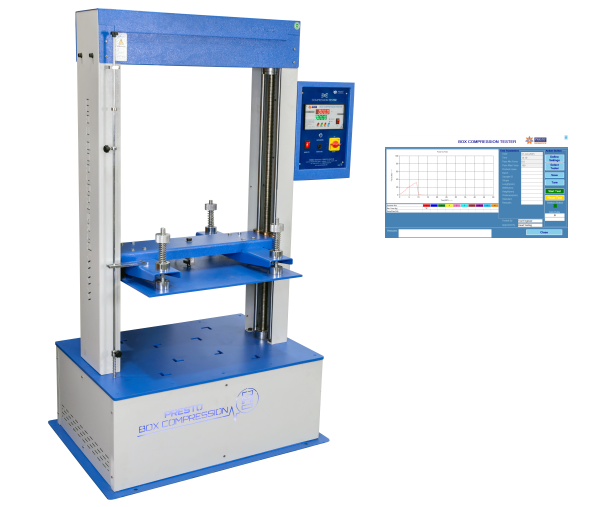

Box Compression Tester Digital

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Cardboard boxes are commonly stacked one on top of the other, during warehousing and storage. So, to ensure that they do not collapse during this, it is necessary to measure their box compression strength. It is based on the principle of measuring the maximum load that the material can withstand without breaking. This process is performed by applying a gradually increasing compression force to a sample until it fails using Box Compression Tester.

Using the equipment, a force-deformation curve can be obtained. This curve helps us evaluate the resistance of a package. It is a reliable equipment that provides accurate information regarding the compressive strength and durability of the package. It enables manufacturers to choose a more resistant packaging and to ensure the contents of the package don’t get damaged during stacking or transit.

Thus, corrugated boxes/cartons/paper packaging can be tested using Box Compression tester. It is widely used to determine compressive resistance, deformation and stacking capability of cartons and corrugated boxes.

Registered Design Patent No. 279106

In stock

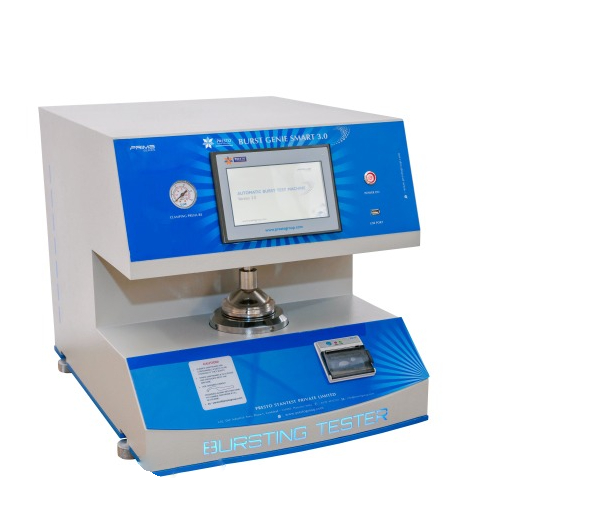

Bursting Strength Tester Genie Smart 3.0

Bursting Strength Tester Genie Smart 3.0 is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene.

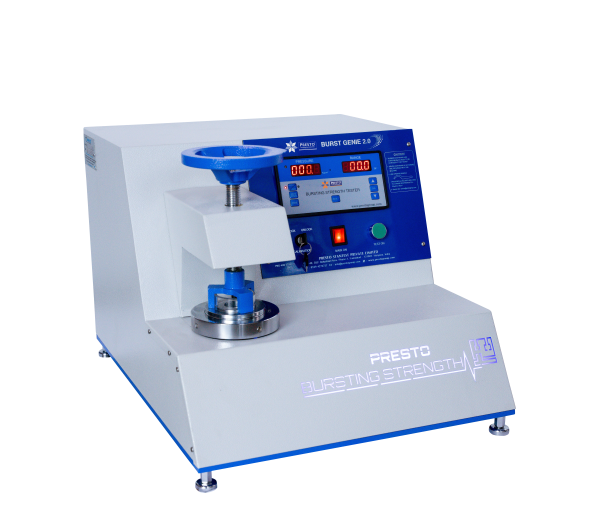

Bursting Strength Tester Genie 2.0

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 2.0 provides a hydraulic pressure on the sample.

In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. A digital indicator with a range of 0 to 40 kg/ square cm, is utilized for the equipment.

Registered Design Patent No. 279109

Availability: In stock

Bursting Strength Tester - Digital Pneumatic

Bursting Strength Tester - Digital Pneumatic is provided with digital display and pneumatic clamping system for determination of bursting strength of paper, paper-board, solid fiber board and corrugated board and boxes. The equipment is widely...

Bursting Strength Tester Digital Cum Computerised Model With Pneumatic Clamping

It is measured by giving a hydraulic pressure through a rubber diaphragm on a circular area of the specimen of CBF under test conditions. The force required to burst or complete rupture of the board is measured through a Digital Indicator.

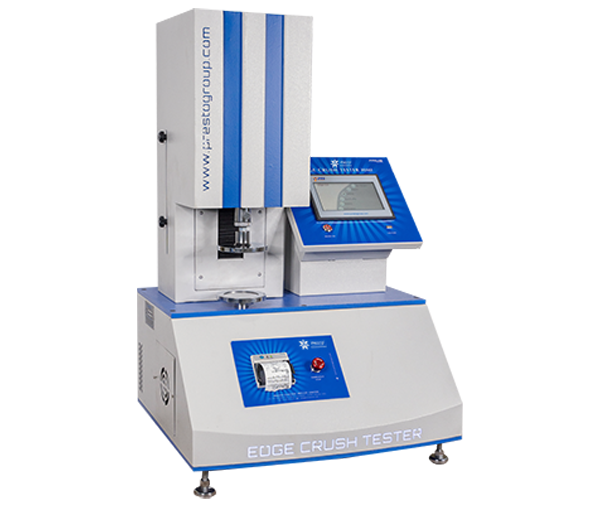

Crush /RCT/ECT /FCT Digital cum Computerised Model

RCT/FCT/Edge Crush Tester is a consistent tool to measure the crush strength of cardboard boxes and packaging containers. RCT/FCT/Edge Crush Tester reveals the crushing resistance in unit Kg/Unit length. It is a rigid support type compression...

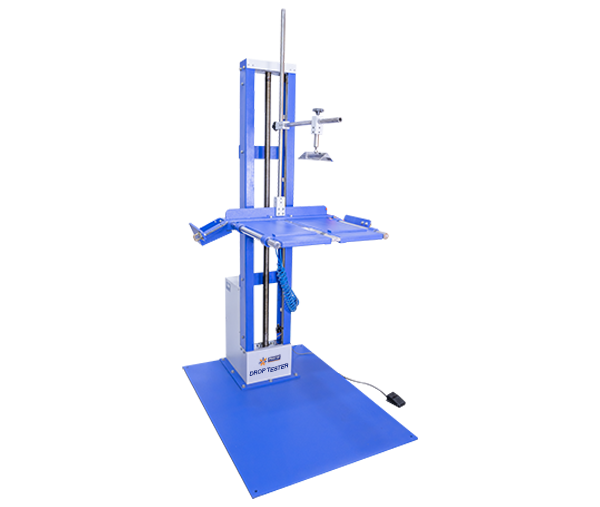

Drop Tester - Manually Operated

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

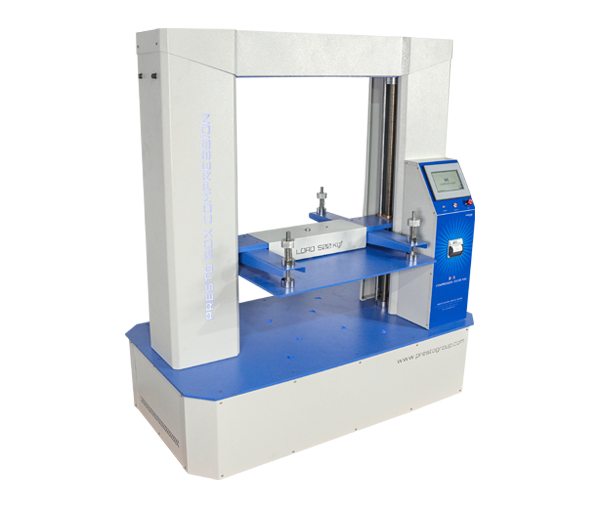

Box Compression Strength Testing Machine

Presto designs and manufactures the box compression strength testing machine to test the quality of the corrugated boxes (used in most packaging industries to pack food item or other items), paper boards, cartons, paper cases, beehive crates and many more.

Drop Tester Motorised Pneumatic

Drop tester is the perfect machine to test the drop strength of the corrugated cartons. It is equipped with a wired remote-control mechanism to eliminate the human interference. The test specimen is observed visually after it is made to fall from a certain height. The instrument work with pneumatic application and used in almost every industry that deals with corrugated cartons.

Box Compression Tester in Bangalore

Corrugated Box Compression tester is utilized to imitate the compressive load which is experience while warehouse storage or during transport. At this stage, the corrugated or carton boxes are often kept each one on the other box. Now you can have Box Compression Tester in Bangalore, Karnataka with unlimited access to expert testing solutions.

Box Compression Tester Digital Mini - Patent No. 341519-002

This equipment is designed to measure ability of the Mini cartons or printed Duplex cartons to resist external compression loads during transit and storage It is important to evaluate the Compression Strength of the Box in order to make sure that the box will be able to resist the anticipated compressive forces and to determine the load that the box will be able to withstand during transit and storage.

The cardboard strength and construction directly impact the amount of weight a box can carry. A box too weak might puncture or collapse. On the other hand, an excessive box means you pay extra for material and add to environmental wastage.

PRESTO Mini Box Compression Tester is manufactured under various Test Standards ASTM D642, ASTM D4169, TAPPI T804,

ISO 12048, and JIS Z0212

Registered Design No. 341519-002

Edge Crush Prima

The edge crush test is one of the common quality tests that will be conducted on the material to ensure that your product will be able to withstand edge crush force. Presto has recently introduced an edge crush-Prima model that has designed this equipment with an automated Human Machine Interface. This lab testing instrument has been designed with a stable and practical mechanical structure with uniform movement over 90 ° alignments. It has been installed with a thermal printer that can instantly print the test result without the hassle of cartridge refill.

Box Compression Tester – NXG Generation Model

Presto has designed a high-quality box compression tester-NXT generation model that has built-in power isolation circuits that provide complete protection against accidental external spikes. It has an enlarged visual display for a better user experience. Besides this, it has been incorporated with a fully isolated communication interface and built-in power isolation circuits that provide the most complete protection against accidental external spikes.

(1).png)

Hot air oven prima series

Elevated temperatures can have a significant impact on the physical properties of many materials. Either it can deteriorate the quality of the product or will lead to product damage. This can have a major impact on the performance of products and structures made from these materials. Thus, it is important for product manufacturers to test the physical properties of the materials at elevated temperatures so as to determine their quality.

Bursting Dual Head for Paper and Board

Paperboard and corrugated board are widely used across various industries. From packaging products to storage boxes, these lightweight materials have become an indispensable part of the packaging industry. However, testing these materials against bursting is an important aspect of quality control. Thus, we at Presto have designed a high-quality lab testing instrument known as Burst Dual Head for Paper and Board

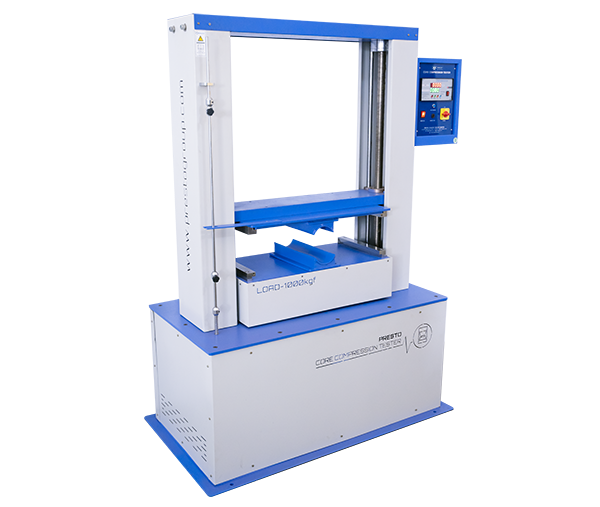

Core Compression Tester Motorized

The Presto newly launched motorized model of core compression tester has been designed for measuring the compression strength of paper cores such as winding rolls of plastic films. It is a highly accurate and reliable laboratory testing instrument that features a powerful motorized mechanism to determine the core strength of materials.

corrugated-testing-instruments

.png)