UTM machine

Our Valued Clients

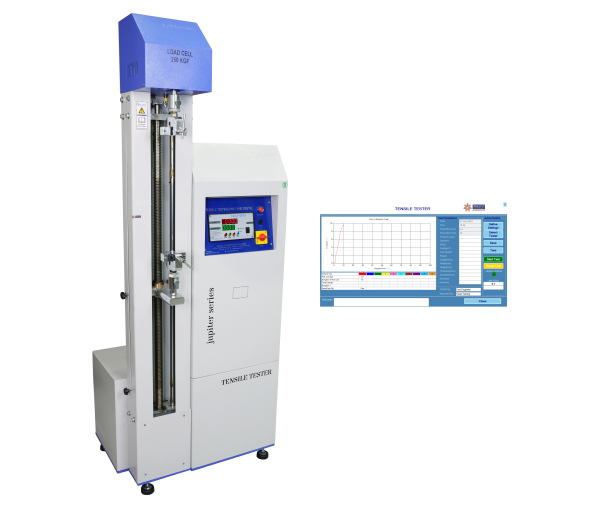

Tensile Testing Machine Digital Cum Computerised Win Test Model

Tensile strength is the stress at which a material breaks or permanently deforms. PRESTO Digital Tensile Tester is a state of the art, highly versatile equipment for checking the breaking strength of packaging related raw materials and finished products.

Zeus Ultimo 3.0 tensile testing machine

Tensile tests are commonly used to measure the mechanical properties of plastics. The force required to break a plastic sample specimen is an indication of the material's strength, while the extent to which the specimen stretches or elongates to that breaking point provides information about its ductility.

Digital Tensile Testing Machine Cap 2500KG

The Presto Tensile Testing Machine is based on the Constant Rate of Traverse (CRT) principle. During the test, the sample is held between two jaws. The upper jaw is stationary, while the lower jaw is made to move at a designated fixed speed with the help of a motor.

Tensile Testing Machine with COF (LCD Display)- Model No. TTMC-LCD

Presto comes with a new model of tensile testing machine with a COF tester. This testing machine is well designed with industry standards like ASTM D618, ASTM D 883, BS 2782, and ASTM D 1894. With the help of this testing machine, you can easily measure the tensile strength along with the co-efficient of friction of various products like plastic films, sheets, and rubber and paper.

UTM machine

The universal tensile machine is manufactured precisely to determine the ductility of various materials like rubbers, textiles, metals & plastics by exerting tensile strength in a structured manner. This allows the operator to assess & evaluate a material’s elongation levels and tensile tolerance that is necessary for the durability & ductility of materials.

The UTM machine is offered with a specimen conditioning accessory and highly advanced features that are responsible for the pinpoint accuracy delivered by the lab testing machine.

Universal testing machine

The Universal Tensile Machine (UTM machine) is an advanced material testing system designed to evaluate the mechanical properties of various substances, such as (rubber, plastics, metals, and textiles). By applying controlled tensile force, this tensile testing system measures a material’s elongation, tensile tolerance, and ductility, ensuring durability, reliability, and compliance with ASTM and ISO standards.

How Does a UTM Machine Work?

The UTM test machine functions by securing a test sample between two grips—one fixed and the other movable. The machine applies a gradual tensile load, and as force increases, it records key parameters such as:

- Tensile strength

- Yield strength

- Elongation percentage

- Break point analysis

- Tensile Modulus

This material stress analysis helps manufacturers determine how much force a material can endure before failure.

Applications of a Universal Tensile Machine

The UTM machine is widely used in quality control, R&D, and industrial manufacturing to assess the strength, flexibility, and performance of materials. Key industries benefiting from this load testing machine include:

- Automotive (testing metal and plastic components)

- Aerospace (evaluating aircraft-grade materials)

- Civil Engineering (ensuring construction materials meet strength standards)

- Packaging Industry (analyzing tensile properties of films, foils, and paper)

Why Choose a Presto Stantest UTM Machine for Material Testing?

A universal tensile testing machine helps manufacturers identify material limitations , prevent failures, enhance product reliability. Compliance with global testing standards like ASTM and ISO ensures that products meet safety and durability requirements.

By integrating a UTM test machine into quality control processes, company can ensure their materials perform optimally under real-world conditions.

Presto Group, India’s leading universal tensile machine manufacturer and supplier. Call +91 9210 903 903 for best quality solutions.