The Ultimate Guide to Universal Testing Machines (UTM)

.png)

Gaurav Malhotra-Testing Instrument Expert

07-03-2025

What is UTM?

A Universal Testing Machine, or UTM, refers to a cutting-edge testing tool utilized to inspect the mechanical character of materials. It is prominently utilized in industries, construction sectors, aviation departments, and in research institutions in order to confirm the strength, elasticity, and toughness of assorted materials. A UTM machine is used in order to apply material testing using test specimens in controlled forces aimed at examining the behavior of those specimens towards stress under different settings.

The greatest benefit of a UTM is that it is versatile; it can perform many types of tests, such as tensile, compressive, bending, shear, and flexural tests, among many others. Scientists and engineers use UTM machines to ensure materials are of the right quality and comply with regulation requirements before used in real-life applications.

UTM Machine Full Form

The complete name of UTM is the Universal Testing Machine. It is "universal" in name because it is capable of executing a variety of material tests on various kinds of materials such as metals, plastics, rubber, textiles, and composites. In contrast to application-specific testers with a single form of test, a UTM is capable of executing various testing needs using interchangeable grips and fixtures, and hence it is a required component in material testing laboratories.

Various parameters like breaking load, compressive strength, adhesion strength quality, bond strength analysis, modulus of rupture, bending load, tearing strength, and puncture strength in flexible products are performed by industries to make good quality products. Presto provides UTM machines with a range of testing.

UTM Machine Used For

The Universal Testing Machine (UTM) is widely used for testing material strength and mechanical properties. It is employed across various industries to evaluate the following parameters:

- Tensile Strength Testing – Determines the ability of a material to withstand pulling forces before breaking.

- Compression Strength Testing – Measures a material's resistance to compressive loads.

- Bending and Flexural Testing – Assesses a material’s response to bending forces and its ability to retain shape.

- Shear and Peel Tests – Evaluate the material's resistance to shearing and peeling forces, important for adhesives and laminated materials.

- Adhesion, Fatigue, and Impact Testing – Determines the durability and performance of materials under repeated stress and sudden impact loads.

Industries such as automotive, aerospace, construction, and packaging rely on UTM machines to ensure their products meet safety and performance standards.

Universal Testing Machine Components

A UTM machine consists of several essential components that work together to perform various mechanical tests effectively. These include:

- Load Frame – The primary structure that houses all the components and holds the test specimen in place.

- Crosshead – Moves up or down to apply force on the test specimen.

- Load Cell – A crucial component that measures the force applied to the specimen with high precision.

- Grips and Fixtures – Secure the test specimen during testing; different grips are used depending on the type of test being conducted.

- Drive System – Provides motion to the crosshead; can be hydraulic, servo-electric, or electromechanical.

- Control Panel and Software – Displays test results, controls the machine’s operation, and records data for analysis.

Each component is critical in ensuring accurate and repeatable test results, making UTMs reliable and indispensable in material testing.

UTM Machine Specification

The specifications of a UTM machine vary depending on its type and capacity. Some common specifications include:

- Load Capacity: Ranges from 5 kN (kilonewtons) to 2000 kN or more, depending on testing needs.

- Speed Range: Typically between 1 mm/min to 1000 mm/min, allowing precise control over loading rates.

- Accuracy: Most UTMs offer an accuracy of ±1% of the applied load, ensuring precise test results.

- Power Supply: Usually operates on 220V/50Hz or 440V/60Hz, depending on the model and region.

- Control System: Available in manual, digital, or computer-controlled versions, providing different levels of automation.

UTM Machine Working

The working principle of a Universal Testing Machine (UTM) involves applying controlled force to a test specimen while measuring the response. The test process generally follows these steps:

- The test specimen is prepared according to the required standards and fixed in place using the appropriate grips.

- The machine applies force through the moving crosshead while sensors record changes in stress and strain.

- The force is gradually increased until the specimen reaches its breaking point or deforms permanently.

- The data is recorded and analyzed to determine material properties such as elasticity, yield strength, and ultimate tensile strength.

By automating the testing process, modern UTMs provide highly accurate and reproducible results, reducing human error in material analysis.

Universal Testing Machine Tensile Test

A tensile test is one of the most common tests conducted using a UTM. It measures a material’s resistance to pulling forces and provides critical data for evaluating its strength and ductility. The test involves:

- Mounting the specimen between two grips.

- Applying a controlled tensile load.

- Measuring elongation and breaking point.

- Generating a stress-strain curve for analysis.

Tensile testing is widely used in industries such as aerospace, construction, and automotive to ensure material integrity and durability.

Universal Testing Machine Working Principle

The working principle of a UTM machine is based on applying mechanical force to a material specimen and measuring its response. The fundamental concepts include:

- Stress – The internal force per unit area within the material.

- Strain – The deformation or elongation of the material under stress.

- Elastic Limit – The maximum stress a material can withstand before permanent deformation occurs.

By analyzing these factors, engineers can determine the material’s mechanical properties and suitability for specific applications.

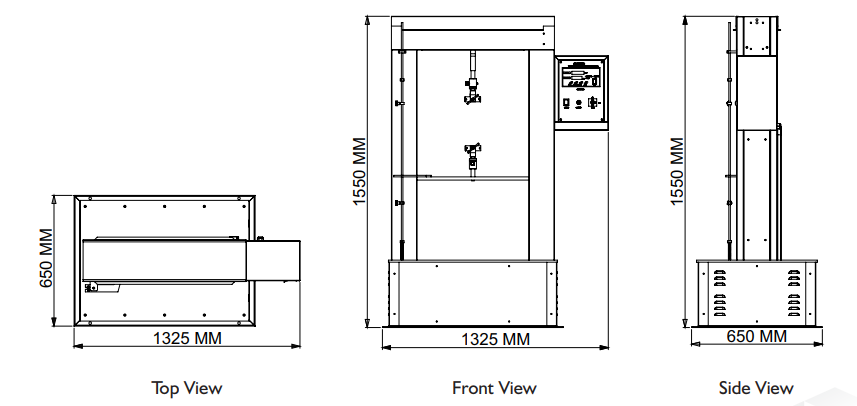

UTM Machine Diagram

A UTM machine diagram illustrates its key components, including the load frame, grips, crosshead, load cell, and control system. The diagram provides a clear representation of how forces are applied and measured during a test.

UTM Machine Parts

The major parts of a UTM include:

- Upper and Lower Crosshead – Controls the application of force.

- Load Cell – Measures applied force with high precision.

- Grips and Fixtures – Hold the specimen securely during testing.

- Hydraulic or Electromechanical Drive System – Controls the movement of the crosshead.

- Digital Display or Computer Interface – Records and analyzes test data.

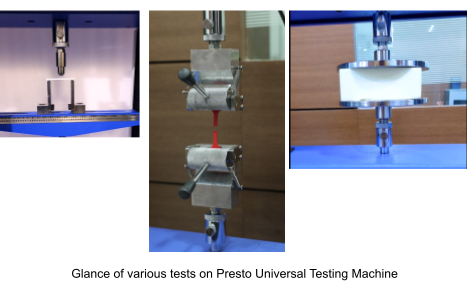

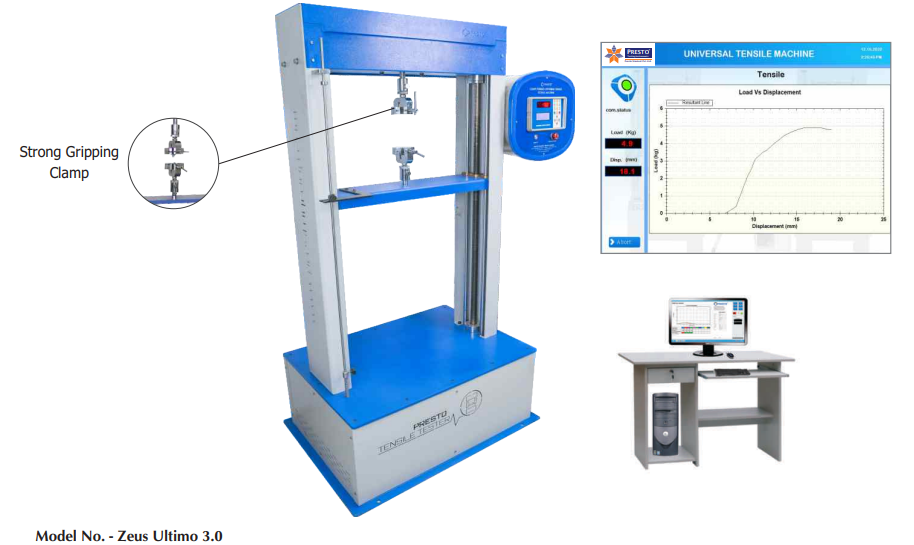

Types of mechanical testing with Presto UTM

A universal testing machine is designed to perform testing like tensile, compression, 3-point bending, peel, bond, shear, adhesion, tear, etc. tests in a single machine, and that too accurately. Hence Presto's advanced universal testing machine is capable of performing the testing with computerized report-generating facilities in Zeus Ultimo software. See how the testing is being performed !!

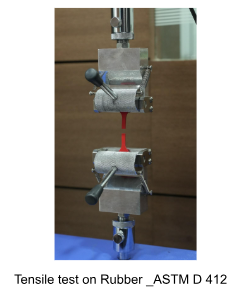

Tensile test: Tensile test is performed to analyze the peak load, breaking load, and tensile strength of a material to determine its suitability for actual applications. The best lab equipment is one that generates automatic reports as it increases accuracy and is less time-consuming to calculate formulas with the least human intervention. The analysis of Tensile modulus, stress-strain curve, and metal testing at 0.2% Proof load are prominent testing in tensile tests. The ASTM E8 standard is prominent for tensile testing on metal.

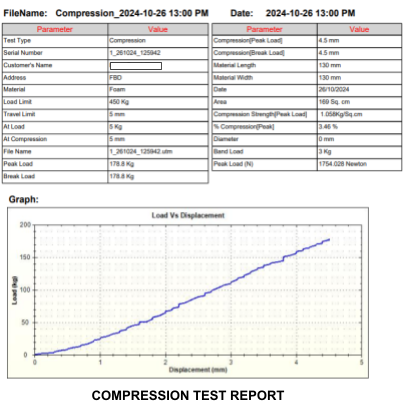

Compression test: It helps in analyzing the deformation that occurs in samples under compressive load. Industries such as foam-making, fiberglass, pipe-making, or bottling industries are concerned with compression testing results. With precise pre-load by applying band load in Presto Zeus Ultimo software users can perform compression tests and indentation hardness test analysis.

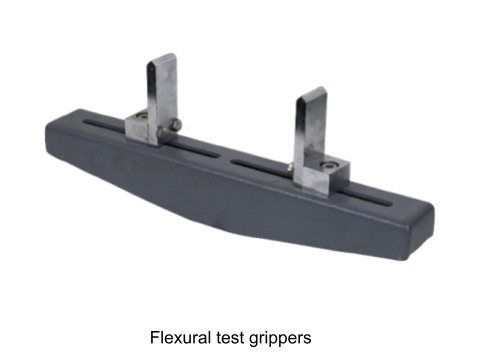

Flexural test (3-point bending test): This test is usually performed to analyze the bending load, modulus of elasticity, and modulus of rupture in materials. Industries such as wood, furniture (lumber veneer), plastics, and electrical insulated items mostly deal in this testing. Check how this test is performed.

Standards such as ASTM D790 and ISO 178 give a scope of determination of flexural properties of samples. The appropriate grippers as per type of testing are required for testing.

Peel/ Adhesion/Seal/ Bond test: These four different kinds of tests are useful for samples in fabrics, flexible packaging, tapes, and labels industries.

The Peel test complies with standards like ASTM D903, and ASTM D3330/D3330M for the T stripping peel strength test.

Adhesion tests at 90 and 180 degrees and loop tack tests are possible in universal testing machines. Hence it is important to choose universal testing machine suppliers who can provide you with all the spares, training, and accuracy assurance.

Tear strength test: The constant rate of tearing (CRT) based tearing test is performed in the Presto Universal testing machine. Standards like ASTM D1004 are being followed in standard. Universal testing machine systems which Presto provides possess this feature too.

Shear test: Standards like lap joint bond strength test in woods, metals, etc samples. ASTM D1002 standard is followed in Shear strength analysis.

Tensile Testing Machine Manufacturers

One of the leading manufacturers of tensile testing machines in India is Presto Stantest Pvt. Ltd.. Presto is renowned for producing high-quality and precise Universal Testing Machines (UTMs) that cater to various industries, including packaging, automotive, and construction. Their machines are designed to deliver accurate results, ensuring superior material testing for quality control. With advanced features, durability, and compliance with international standards, Presto’s testing equipment is a preferred choice for manufacturers seeking reliable material testing solutions.

FAQs

What is a universal testing machine?

A Universal Testing Machine (UTM) is a device used to test the mechanical properties of materials under various loads. It is used for tensile, compression, bending, and shear tests, making it an essential tool for material quality analysis in industries like manufacturing, automotive, and construction.

What does a UTM machine do?

A UTM machine applies controlled forces to a test specimen to measure its strength, elasticity, and resistance to deformation. It provides valuable data on material properties, helping manufacturers ensure product quality and compliance with industry standards.

What is the difference between UTM and CTM?

A Universal Testing Machine (UTM) is used for testing various material properties, including tensile, compression, and bending. A Compression Testing Machine (CTM), on the other hand, is specifically designed to measure the compressive strength of materials like concrete and bricks, making it more specialized in nature.

What is the cost of an ATM universal testing machine?

The cost of an ATM Universal Testing Machine varies depending on specifications, load capacity, and features. Prices typically range from INR 1.5 lakh for basic models to INR 15 lakh or more for high-end digital UTMs with advanced testing capabilities.

What is the typical UTM machine price in India?

The UTM machine price in India typically ranges between ₹2,00,000 and ₹6,00,000. The cost depends on factors like load capacity, software features, automation level, and brand reputation.

Summary & Final Thoughts

A Universal Testing Machine (UTM) is a versatile and essential tool for evaluating the mechanical properties of materials. It helps industries ensure that their materials meet required strength, durability, and performance standards. Whether for tensile, compression, or flexural testing, a UTM provides precise and reliable results, making it indispensable for quality control and research applications.

UTM Machine Price in India

Looking for the best UTM Machine Price in India? Get in touch with Presto Stantest Pvt. Ltd. for high-quality Universal Testing Machines at competitive prices. Contact us today for a quote and expert guidance!

- Call: +91 9210 903 903

- Email: info@prestogroup.com

- Visit: Presto Stantest Pvt. Ltd.

Ensure accuracy and reliability in material testing with Presto’s UTM machines—built for excellence and precision!

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

How it works

Get a Quote