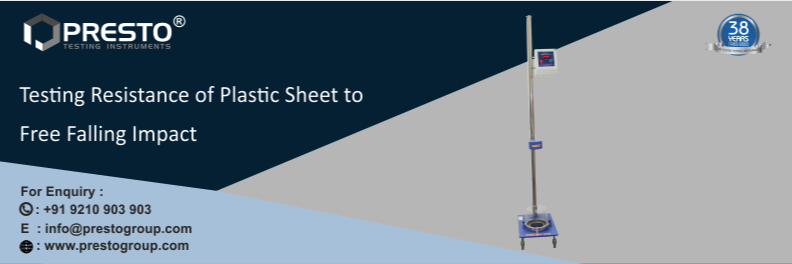

Testing Resistance of Plastic Sheet to Free Falling Impact

The electromagnetic release and hold mechanism is specially designed to perform an error free testing. The holding of the dart at a particular height and holding it still prior the fall add to precision of testing, which a human can never perform. And afterwards, the release of dart at a specified speed can only be done using electromagnetic forces. The dart which is selected for impact test ranges in weight. There are options of distinct weight for dart heads. It can be chosen as per the test requirement.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote