Test Ductility of Metals with Cupping Test

Metals are widely used all over the world and have acquired a huge area in different production vertical to manufacture domestic products as well as industrial goods. The wide areas of fields where metals are used on a large scale are electrical products, construction goods, automobiles, and many more. The fields where metals are used are very crucial in nature, and there is no space for defects in these industries because these defects can directly affect the safety of the users and can lead to fatal accidents and horrible consequences. Therefore, it is essential to use only high-quality of raw materials to produce the only high-quality end product. These conditions and requirements make the manufacturers in metal industries more alert to produce high-quality metal products with extra consciousness to ensure the better quality of the products.

How can the quality of metals be assured?

Manufacturers need to ensure that best quality of the products that they deliver to their customers by performing certain types of tests on those products by using highly sophisticated and high-quality testing instruments. Using testing instruments, the manufacturers can measure the properties of the metals such as chemical composition, physical strength and helps to measure the performance of the products under different test conditions. These conditions help the manufacturers in determining the factor of safety to ensure the usage of the metal products and help provide better quality to the customers. To ensure the quality of the products, the manufacturers need to perform the quality testing procedure at different stages of production such as raw material inspection, manufacturing process, till the final product. Ignoring the quality of the products at these stages can lead to several flaws in the quality of the products which directly affects the revenue & goodwill of the business.

Cupping Test – Modern Test Method for Testing Metals

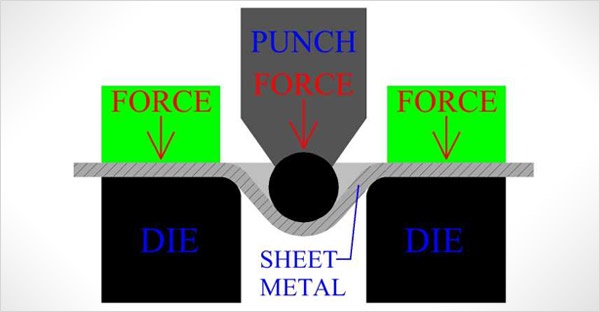

One of the major test procedures that are conducted on the metals is Cupping test. This test is performed to measure the ductility of the metals. To perform the cupping test, a test sample is placed below the shearing force, and the force is applied to the metal using the round indenter. This indenter applies continuous pressure on the specific area of the metals sheet and results in a formation of the small cup on the test sample. The load sensor which is presented inside the indenter helps to record the force which is applied to the metal and in this manner the strength or ductility of the metals can be measured.

To know the technical specifications of the cupping tester, contact our experts.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote