Tired of Inconsistent Wall Thickness? The Magna-Mike 8600 Ensures Precision in Every Measurement!

Gaurav Malhotra

23-09-2024

How many times have you been frustrated with variability in your wall thickness product? Maybe you had quality-control issues or returned goods because of a poor measurement. Measuring the actual thickness of walls is crucial to product integrity and proper operation of your products. Let's start our tour of measuring instruments regarding thickness-measuring tools, and we'll point out the Magna-Mike 8600 wall thickness gauge as one of the most popular kinds. Let's see how this new innovative wall thickness measurement tool can help you hold accuracy and reliability.

What is Wall Thickness Measurement, And Why Does it Matter?

So, let's talk a bit on the subject of wall thickness measurement itself before I delve into the specifics of the Magna-Mike 8600. Ever wonder why wall thickness is a big deal? It's one of the things that you should pay attention to while working on the manufacturing of something. The reason why measurements of wall thickness are really important, they will determine the strength, and durability of any material you work with, metals, plastics, or composites.

How to Measure Wall Thickness?

The wall thickness measurement can be performed through an ultrasonic test, mechanical gauge, and even several other methods. Although this is not the most scientific tool, the wall thickness gauge, an NDT kind, is the most handy one.

With such a tool, a producer will first evaluate the raw material, and then determine whether it is intact, without causing damage.

Have you ever used any measurement tool, as far as wall thickness is concerned? If you are using one, what challenges are you facing?

Magnamike 8600

Now, let's look at one of the leaders in the market, the Magna-Mike 8600 wall thickness measuring device. So exclusive, and reliable is it that it comes directly to customers with desirable features, but what does it make a must-have for manufacturers?

Key Features of the Magna-Mike 8600

High accuracy: The Magna-Mike 8600 employs advanced magnetic induction technology, that will be able to provide very high measurements of wall thickness in extreme conditions. This level of accuracy is important, in areas in which one needs to underscore the importance of material integrity.

Versatile use: The Magna-Mike can read the wall thickness of thin plastics, to thick metals. So if you have experience struggling, to measure different materials, with some of the equipment you have, you can use the Magna-Mike for your measurements.

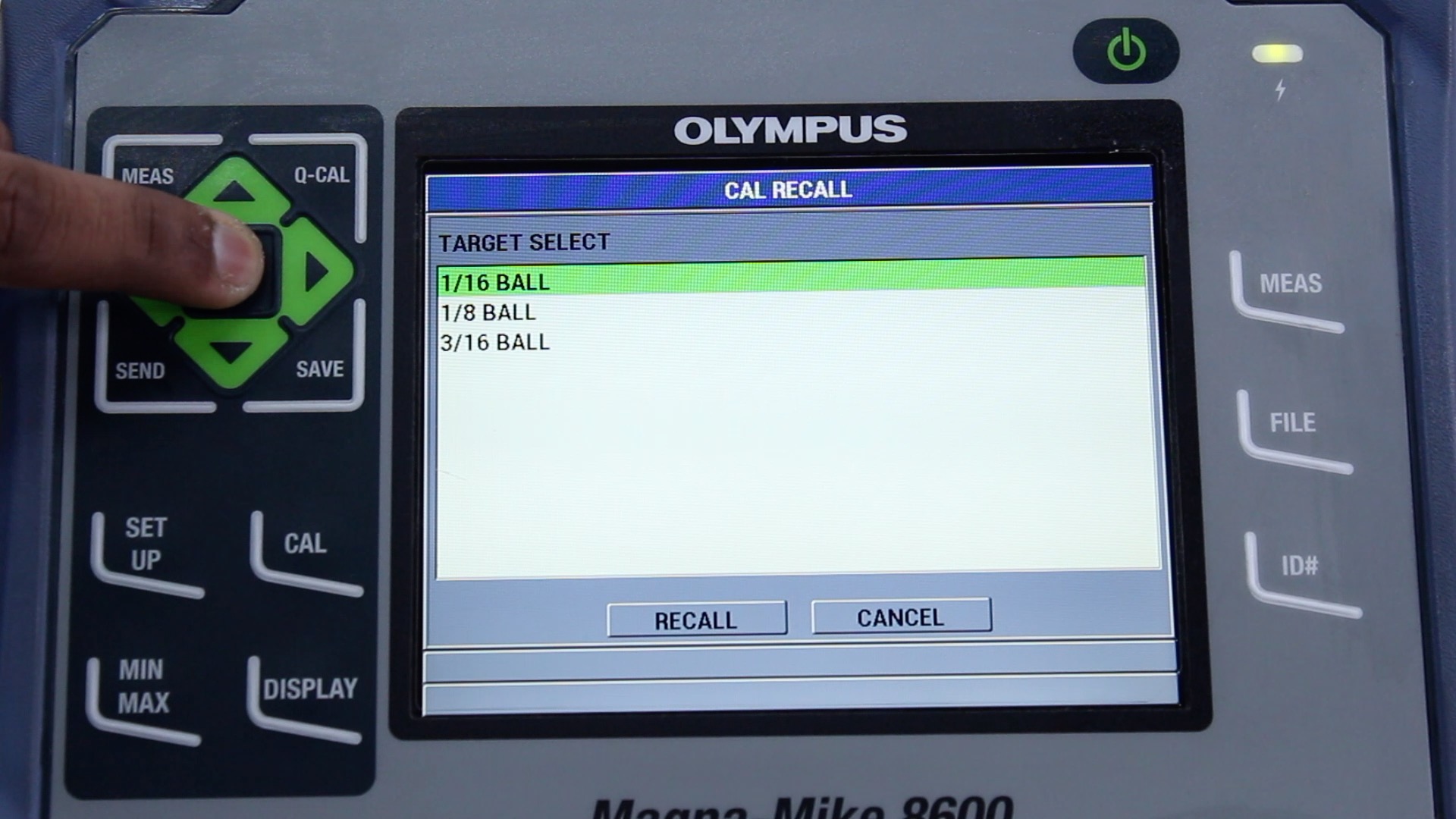

Intuitive ease-of-use interface: The product has an intuitive interface, that requires very minimal practice, on how to use it for production, meaning that training of staff can be less and more time spent producing. How Important is Ease of Use in Your Measurement Processes?

Non-Destructive Testing: As noted above, the Magna-Mike 8600 is a non-destructive measurement tool, so, you do not need to sacrifice your materials, for their supposed intended applications, and yet still know you have great data. Nice, is it, to know you might test without hurting?

Principle of the Magna-Mike 8600

What is the principle of Magna Mike 8600?

The Magna-Mike 8600 takes advantage of the principle of magnetic induction. It uses a probe to create a magnetic field, which is felt as it interacts with the conductive material of the object, that you are trying to measure. Changes in the magnetic field are used to measure precise wall thickness.

16 Gauge Wall Thickness Explained

Many manufacturers will often hear references to things like "gauge" referring to the wall thickness of parts. What do those words mean, though-from "16 gauge" wall thickness, that is?

What is 16 Gauge Wall Thickness?

In the United States, gauge is a term measuring the thickness of metal in terms of how thick it is. For example, 16-gauge steel is approximately 0.0598 inches or 1.519 mm in thickness. Such measurements can be very important when you're manufacturing components that have to meet certain criteria.

How much will it cost me to get the Magna Mike?

The price for the Magna Mike 8600 largely depends upon where you are buying it from as well as if you require any kinds of accessories or additional features. As an overall package, you should expect to pay anything from $3,000 to $5,000(₹250,890 to ₹419,900.) to get your precision high-end wall thickness gauge.

How to Buy the Magna-Mike 8600

Want to unlock the Magna-Mike 8600 for your next manufacturing project? Here are some steps for you to follow:

Research: Compare prices from various distributors. You need a supplier that can be trusted, one who specializes in thickness measurement equipment.

Ask for a Demo: Most of the sellers offer demos or trial periods. This would be an excellent opportunity to see how the device works in real-time.

Ask About Support and Warranty: For customer support and warranty provisions. This is the case with every investment in equipment.

Buy Now: Having read through, done proper research, and made up your mind confidently, it's time to place a buy!

In simple words, does the inconsistency wall thickness problem have a solution in your manufacturing? Then you should opt for the Magna Mike 8600. It stands perfectly well on precision, versatility, and ease of use, so quality and reliability will never be compromised in your products.

Are you ready to take your measurements one notch up, for that wall thickness? How do you think adding value to the quality of equipment affects your productivity? Accurate measurements today, make a difference in tomorrow's performance of the product!

Share your experiences or any questions you'd like to bring up in the comments below. Every piece of feedback counts!

Give us a call at +91 9210 903 903 or mail us at info@prestogroup.com.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote