How to Perform the Charpy Impact Test in Best Way?

In some materials, knowing the impact strength is a very important parameter, e.g. metal and plastic. As plastic is most commonly used packaging material and metal is most commonly used raw material in different industries. Impact test determines a very important quality of the test, i.e. ductility. Performing a Charpy test will give an estimate whether the metal is ductile or brittle. The way you are using Charpy impact tester determines the accuracy of the test results. There are some precautions that need to be taken while performing Charpy impact test. This short guide would help you in performing the Charpy impact test in best possible manner.

Learn How to Perform Impact Test in Easy Way

Preparation of Sample

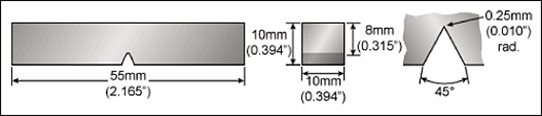

First of all, the charpy test cannot per performed on the final product sample. You need to take the sample of a material which would take the shape of the final product, e.g. to test the endurance of remote control, you will not test the final product sample with this instrument. Instead, you will take the sample of plastic case in which every component is assembled. The test sample should be a rectangular strip of as per ASTM A370 standards. Make a V-notch in the middle of the sample. You need a V-notch cutter to make this cut in the sample. Making this cut manually is certainly not possible as this would result in inaccurate results.

Performing the test

Fix the sample in the fixture so that V-notch lies just near the anvil, in the vertical direction. Depending upon the sample to be tested, attach a weight on the pendulum. The pendulum is made to fall free from the angle of 150°. As pendulum will hit the sample, it will break the sample from v-notch. How much force is applied by the pendulum to break the sample will be calculated by the Charpy impact tester and display it on the LED screen. The unit of calculating impact strength is J/m.

Precautions to be taken

As such, there are no special precautions to be taken except the placement of sample in the fixture. If the V-notch is too high or too in the clamp, the test results will not be accurate. If the sample is too high, the strength calculated is too low than actual. On the other hand, if the sample is too low, the force calculated will be too low. So, placement of sample has to be done very precisely.

Advantages of Charpy impact test

This test is very simple to perform and results delivered are very fast. As it helps in assessing the quality of material, it holds a very important position in quality management laboratory. Presto Group offers a strong Impact test machine that is useful for measuring Charpy impact strength and Izod impact strength also.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote