How to Measure Coefficient of Friction of Plastic Films?

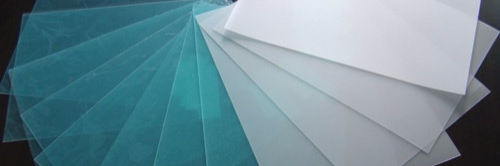

Coefficient of friction testing is done in poly film packing industry to assess their stacking capacity. Plastic film has very low friction due to which there are ample chances of slippage. The coefficient of friction testing is done to determine the easiness with which two facades when placed in contact with each other are able to slide on one another. The coefficient of friction testing helps to determine two values, i.e. Static friction and Kinetic friction. Static friction contributes to determining the energy required to start the motion between two surfaces while the kinetic friction contributes to determine the resistance to sliding once both the facades are in relative motion.

While performing this test, there are many things which are considered to get the accurate test results. Anything on the surface of the testing sample can lead to inaccurate test results. Cleanliness on the surface of the specimen is matter of consideration. Anything that increase or decrease the friction should be removed. Things like dust and grease can impact the results considerably. Further during testing to ensure freedom from grease and dirt that could unfavorably affect test results. The standard test method ASTM D 1894 is the best. With this, film manufacturers can assure best test results.

How to Perform the Test?

In this test, two specimen are cut out from the same sample. In this test, one sample is placed on the platform and other is placed on movable block. Both samples have similar texture facing towards each other. The movable block is further attached to the pulley. As soon the test starts, the block starts to move on the sample. The resistance caused by the block is sensed by the machine and coefficient of friction is displayed on the screen.

Presto Stantest, a well-known manufacturer of testing instruments, offer a wide assortment of paper and packaging testing instruments. Presto’s Coefficient of friction tester helps to determine the coefficient of initial and sliding friction of papers, films, plastic sheets and pipes. The test is performed to analyze the stacking ability of plastic films and sheets. Moreover, the test helps the manufacturers in the plastic industry to avoid accidents caused due to various problems in packaging, loading and in transporting goods and materials. The uneven thickness of sheet leads to enhanced friction which leads to uneven strength of a plastic material. The coefficient of friction testing technique implicates the level of mistreatment a plastic material can endure without affecting the inside content.

Check Table of Coefficient of friction to other materials. To check price of coefficient of friction tester contact to us.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote