Hot Air Oven: Test Solution for Effective Material Testing

Gaurav Malhotra-Testing Instrument Expert

10-02-2025

A hot air oven is essential in testing devices whose primary aim is to find out the physical properties of various materials at high temperatures. Specialized test cabinets that determine the ageing properties, heat resistance, and durability of materials are crucial for quality assurance. Hot air ovens for rubber, plastics, pharmaceuticals, and microbiology laboratories assist in quality control in such industries where high-quality standards prevail.

Advanced heating technology is used to make the hot air oven, which is designed on the principles of forced air circulation and thermal convection. This will make sure that it heats uniformly to get the proper and reproducible test results. Modern hot-air ovens possess features such as intuitive graphical controls, precise temperature regulation, and high-grade insulation, thus being more efficient and reliable in a testing environment.

Key Features of Hot Air Ovens

Hot air ovens are engineered with the most modern technology to improve the accuracy of testing and the convenience of operation. The following are the most notable features:

1. Graphical Menu System:- This intuitive graphical menu makes test configuration and operation straightforward for lab technicians and industry professionals alike.

2. PT-100 Sensor-Based Precision Temperature Control:- Equipped with a highly sensitive PT-100 temperature sensor, hot air ovens provide precision control over the heating process with consistent thermal conditions within the chamber.

3. Uniform Temperature Distribution:- A rapid air circulation fan imported from Germany ensures homogeneous heating throughout the chamber, preventing temperature fluctuations and maximizing test reliability.

4. High-Grade Glass Wool Insulation:- Imported glass wool insulation minimizes heat loss, thus maximizing thermal efficiency while maintaining stable internal conditions.

5. Advanced PID-Based Temperature Controller:- A microprocessor-based PID controller with auto-tuning capabilities reduces deviations to maintain precise temperature regulation. Test repeatability is enhanced.

6. In-built programmable Soak Timer:- The programmable soak timer allows users to set up specific time durations for heating cycles to ensure consistency in testing procedures.

7. Digital Display and Data Logging:- There is a monochrome LCD to present real-time values, such as test values and graphical representation. Event data recording is done with date and time stamping with its 2GB memory and up to 4 lakh entries.

8. Secure PC Connectivity:- The system can be easily communicated externally with the help of an RS 485 serial port, which facilitates easy data analysis and remote monitoring.

9. Effective Sterilization and Pasteurization:- Hot air ovens are extensively used in sterilization applications. The requirement for a specific temperature and duration for the effective elimination of microbial contaminants necessitates the support of the system. A sterilization temperature of 160°C to 180°C is supported for a while of 1 to 2 hours for effective microbial decontamination.

Applications of Hot Air Ovens

A comprehensive role of hot air ovens is observed across the industries undertaking critical testing functions such as:

1. Use of hot air oven in laboratory:- Hot air ovens serve as a dryers, heat treaters, and sterilizers for various laboratory work. They have significant importance in research and development labs where tests on the material's heat resistance are performed.

2. Hot Air Oven Sterilization:- Hot air sterilization utilizing the hot air oven is the most accepted method of laboratory equipment sterilization. The processes through the destruction of microbial life through high temperatures require absolute sterilization to ensure the safety in pharmaceutical labs and clinical labs.

3. Heat Aging and Deformation Testing:- Hot air ovens are used by the rubber and plastic industries to simulate long-term heat exposure, to evaluate material durability and resistance to deformation.

4. Compression Set and Heat Resistance Testing:- Hot air ovens are used by the elastomers, adhesives, and polymers manufacturing industries to assess how the materials are going to behave with long-term exposure to heat so that the product serves to its finish and lasts longer.

Hot air oven and autoclave: Know the Differences

Hot Air Oven and Autoclave are both used for sterilization; however, they differ in the mechanism of operation and in applications.

Feature of Hot Air Oven and Autoclave

- Sterilization Method Dry Heat Moist Heat (Steam)

- Temperature Range 160°C - 180°C 121°C - 134°C

- Time Taken for Sterilization 1 - 2 hours 15 - 30 minutes

- Substrate type which can be used Glassware, powders, metal instruments Liquids,

- culture media, surgical tools

- Killing micro-organisms Effect on bacteria, viruses, spores Highly effective at heat

- labile biological contamination

The use of either a hot air oven or an autoclave depends on the material. Laboratories prefer handling non-heat-sensitive materials since heating with a hot air oven is uniform with no interference by moisture.

Advantages and Disadvantages of Hot Air Oven

Just like any testing equipment, hot air ovens also have their respective advantages and disadvantages.

Hot air oven advantages and disadvantages:

Advantages:

- Accurate Temperature Control – It ensures uniform heating for reliable test results.

- Uniform Heat Distribution – Prevents localized overheating, making it more reliable.

- Efficient Sterilization – Effectively decontaminates materials without the use of chemicals.

- Energy-Efficient Design – High-grade insulation minimizes heat loss, optimizing energy consumption.

- User-Friendly Operation – Digital controls and programmable features make it easier to use.

Disadvantages:

- Longer Sterilization Time - Compared to an autoclave, a hot air oven will require longer hours of exposure under high temperatures.

- Inapplicable on Liquids- The dry method of heat doesn't work out for liquids or heat-sensitive material.

- Higher Initial Expense - High-tech models with the inclusion of a PID controller, data logging ability, etc will cost more upfront.

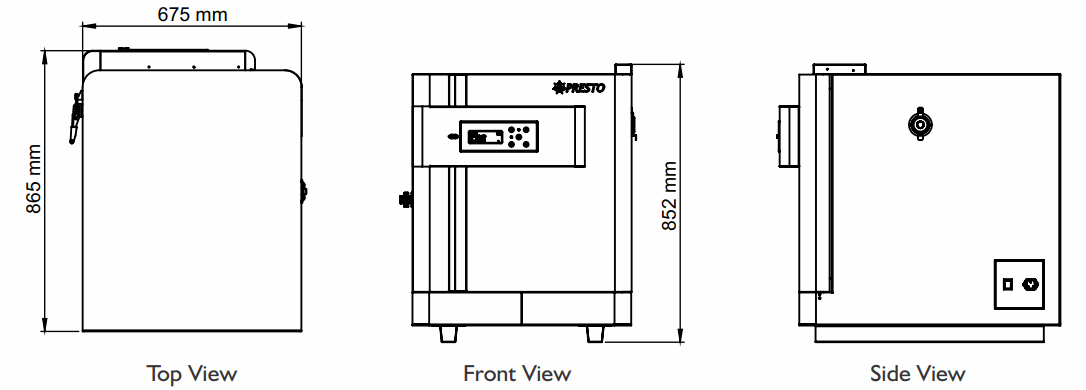

Presto designs and manufactures high-performance hot-air ovens designed for industrial testing and laboratory applications. Our advanced forced air circulation system ensures uniform heat distribution, guaranteeing precise and reliable test results.

We integrate state-of-the-art microprocessor-based PID controllers for optimal temperature regulation, minimizing test variability and adherence to industry standards. Our hot air ovens come with feather-touch controls, a graphical LCD interface, and extensive data logging capabilities, making them the best for professionals seeking high-quality testing solutions.

FAQs

1. What is the difference between an airfryer and a hot air oven?

An air fryer uses rapid air circulation and a heating element to cook food quickly with minimal oil, while a hot air oven uses dry heat for sterilization, drying, or baking over longer periods.

2. Is there any use of a Hot air oven in microbiology?

Yes, hot air ovens are frequently used in micro laboratories for glassware, Petri dishes, and metal equipment sterilization.

3. How does a hot air oven ensure uniform heating?

A high-efficiency air circulation fan and thermal convection system ensure efficient and uniform temperature distribution within the chamber.

4. Which industries are most likely to use hot air ovens?

Hot air ovens are employed in rubber, plastics, pharmaceuticals, research laboratories, and microbiology industries for checking material resistance. A hot air oven is used for sterilizing materials as well.

Hot air ovens are an essential tool in industrial material testing laboratory research, as well as microbiological sterilization. Providing accurate temperature control, uniform heating, and proper sterilization makes it an indispensable tool for almost all industries.

Presto's hot air ovens are the most performance-accurate and easy-to-operate solutions for professionals looking for reliable testing services. Investing in a quality hot air oven ensures that industries will uphold quality standards while optimizing testing and sterilization processes.

Looking for the best Hot Air Oven Price? Contact us today to get competitive pricing and high-quality products. For more details, call +91 9210 903 903 or email info@prestogroup.com.

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote