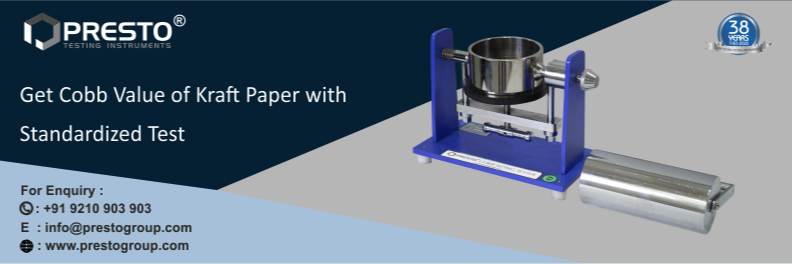

Get Cobb Value of Kraft Paper with Standardized Test

Kraft paper with its various qualities is used for multiple applications which include, Paper sack for cement, food, chemical powders, flour bags, grocery bag, envelop etc. It is to be noted that all these applications may be different from each other but require their material to be of good quality, especially its absorptiveness. Every single application need a distinct level of absorption quality and therefore, it is important for manufacturers to fulfil this requirement using standardized Paper & Paper Board Testing Instruments.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

you may also like

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote