5 Key Benefits of Using a UV Environmental Test Chamber for Your Business

Gaurav Malhotra

26-10-2024

In the present competitive environment of industrial manufacturing, the product lifespan becomes highly important. Material degradation and discoloration due to UV exposure followed by color fading and performance degradation are common problems encountered by an industrialist. Tackling this issue, which is widespread and pressing, involves the need for a UV Environmental Test Chamber as a must-have tool in the quest of manufacturers for quality and durability.

Understanding the Problem: UV Exposure Effects

UV radiation, mostly from sunlight, is one of the most prevalent exposures that most materials including plastics, paints, and textiles face. Unless such items are properly tested before use, they may thus become weakened in strength, lose elasticity, or lack aesthetic appeal in addition to causing a gigantic blow to the reputation of the brand or customer satisfaction. Actually, the research shows that long UV radiation exposure can cut the life expectancy of some materials by as much as 30%. This is going to cost industrialists thousands of big numbers in terms of losses and waste. The only solution is a UV test machine to replicate and accelerate UV exposure on materials, allowing manufacturers to judge their products' durability in simulated conditions.

Presto: The Feel of Experience

Presto is one of the best-known companies in the market that deals with sourcing quality testing equipment. This company has years of experience, innovation momentum, and numerous testing instruments, to name a few, including the UV Environmental Test Chamber. The quality commitment and the expectations of customer satisfaction can be reflected in the intense after-sales support. Presto has also catered for various clients in other fields; hence, it has emerged as the best firm in this area, of material testing.

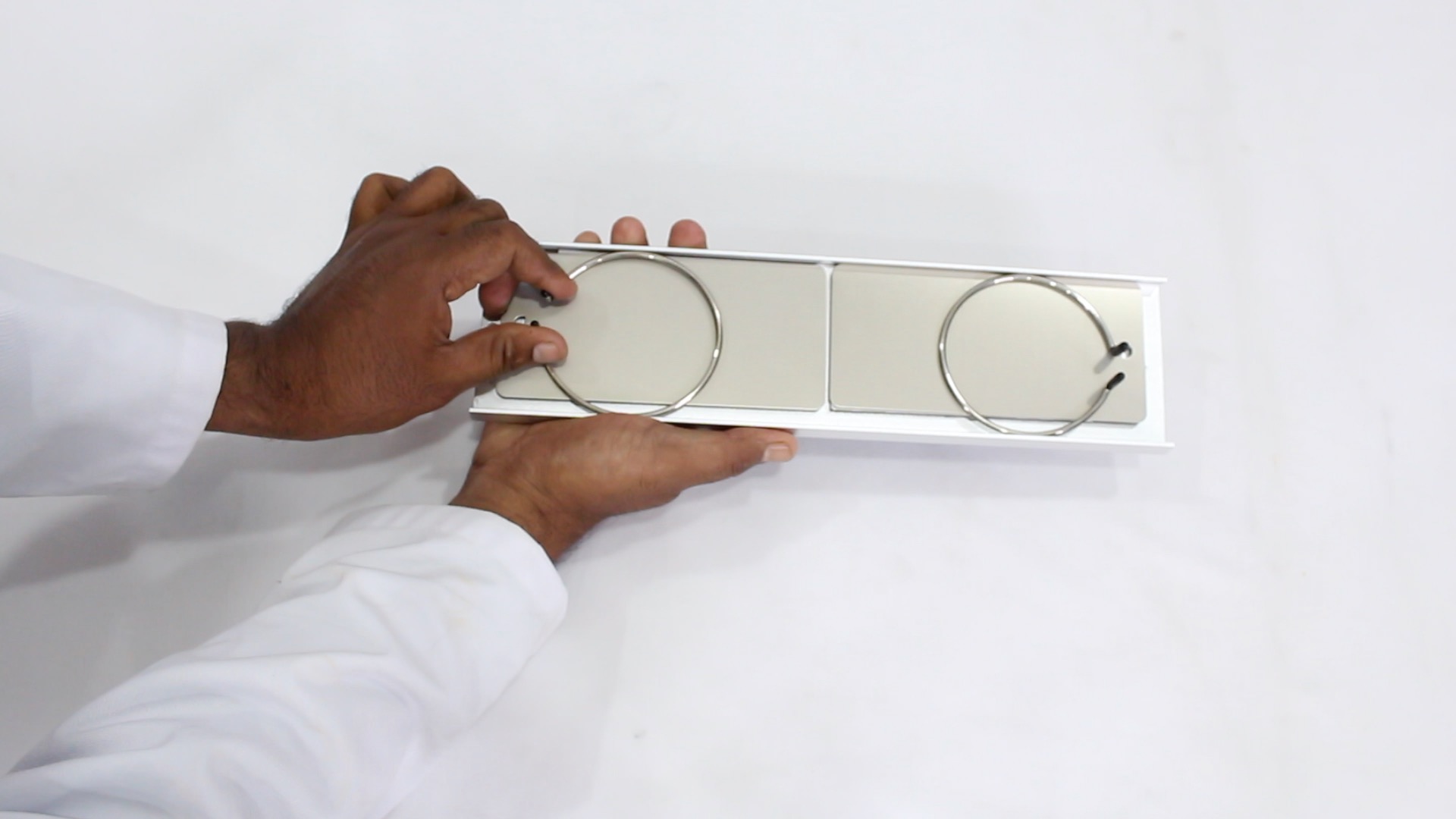

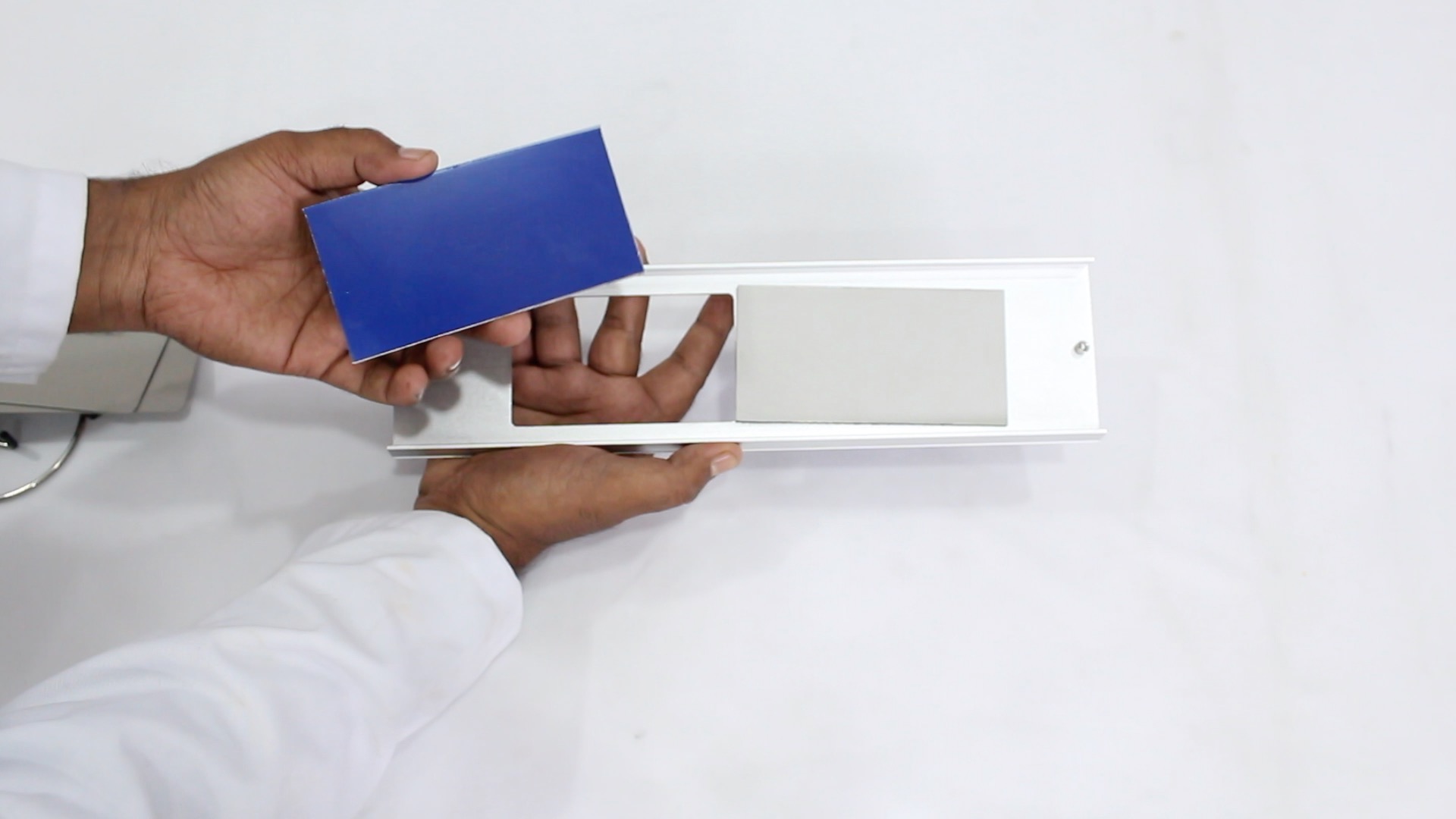

Technical Description of UV Environmental Test Chamber

The technical specifications should be understood by the person before buying a UV Environmental Test Chamber. The features given below help in understanding its importance:

Power Supply: 220±22V/50±0.5Hz

Temperature Range: From RT+5 C to 80 ºC

Test Time Limit: 1h to 99999h

Spray TimeLimit: 1min – 99999min

Life of Lamps: 1600h

Maximum Irradiance of the new lamp: UVA Lamps can reach 0.7 W/m, UVB Lamps can arrive at 0.4W/m

Distance of Specimen from the lamp: 50mm

Speed of Rotating Frame: 3.7 rotations per minute

Flow Rate of water pump: ≤ 7L/min

The order can be placed on the basis of lamps:

UVB lamps (20W/313nm)

UVA lamps (20W/340nm)

UV Environmental Test Chambers: The Revolution in Business Behaviors

Add UV Environmental Test Chambers to your test series, and you will be able to revolutionize business behaviours as it assures the quality of your products. Here is how the equipment will do great things for your business operations:

Saves Dollars

All the costs of product recall and replacements would be avoided at the early stages of production due to the identification of materials that are resistant to UV degradation. For example, if an amount of five defective units can be saved every month from damage by UV degradation at a cost of INR 10,000 per unit then that amount works out to be INR 6,00,000 annually.

Time Saved

Accelerated tests that take place under controlled conditions lower the time taken to validate the product. It gives manufacturers reliable results in weeks as opposed to waiting for months to ascertain how the product will perform in real conditions. This saves time spent on bringing a new product to the market. It also gives companies an edge over their competitors.

Resource Optimization

The UV Test Chamber use would further help the manufacturers to optimize their material of choice and manufacturing processes, thereby maximizing minimal waste materials. Further, with the savings coming along with increasing sustainability enhancement, which has recently been the focus area for most of the modern industrial settings, costs would be reduced even more.

Strict testing of products based on UV exposure will go a long way in making designs and formulations for stronger performance and durability of the product.

If the product is able to pass through the test of UV, then it shall be within the expectations of consumers as a durable product with a good word-of-mouth assessment of the brand.

Compliance/Standards

This UV weathering test chamber offers a product based on industry-standard durability tests. Ensuring compliance with standards leads to accessing new markets as well as increasing the client's confidence in the material, therefore increasing the business profitability.

Be Smart Today.

Adding UV Test Chamber to your quality assurance program is not only advisable but it is essentially a must for the forward-looking industrialist committed to excellence. It saves a great deal of time money and resources and increases the quality of the product and the reputation of the brand simultaneously.

Do you have the will to forge ahead towards the upgrading of your product tests and lifetime? Then, be a shrewd businessman or woman and invest in a UV weathering test chamber. Don't let UV exposure compromise your business—make the smart decision for your future.

FAQs

What is UV weather testing?

It tests for the ageing effect of materials caused by ultraviolet light and other environmental exposures. The corresponding simulation is caused by sunlight, water, temperature fluctuations, etc.

How can UV testing be accelerated?

Accelerated UV testing can be made through a UV Environmental Test Chamber that would simulate the effects of prolonged exposure to UV light within a much shorter period of time, thereby hastening material durability assessment.

What is the UV test method?

The UV test method is a technique in which materials are tested in an environment under UV radiation. Thereafter, it checks their resistance to various performance-related problems such as degradation and discolouration.

What are the standards for the weathering test?

ASTM G154 and ASTM G155 are the standards, which come forward with procedures to consider the impact of UV exposure on various materials.

Thus, by learning these FAQs, you will be able to arm yourself with the necessary knowledge that would help make appropriate decisions about UV testing and its implications for your business.

Phone: 91 9210 903 903

Mail: info@prestogroup.com

you may also like

- The Ultimate Guide to Lab Testing Equipment: Ensuring Quality with Precision Instruments

- GSM Calculator Guide: How to Measure Fabric, Paper & Plastic Weight

- What Is a Gloss Meter? Working Principle, Uses & Benefits Explained

- Applications of Tensile Testers in Plastic, Metal & Rubber Industries

- How UV Chambers Help Manufacturers Beat Sunlight and Weather Challenges

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote