Why Testing of Kids Apparels And Accessories Are Important?

When it comes to manufacturing goods for children, every industry is very cautious, be it toys, garments, food items, cutlery or any other thing. The garment industry is one such sector which involves in hefty risk assessment management and frameworks. When apparels and accessories are designed and manufactured, studying and understanding the behaviour of children of specific age group is indispensable. One common characteristic that every child has is unaware behaviour. They are least interested or bothered about the consequences or hazards related to a product.

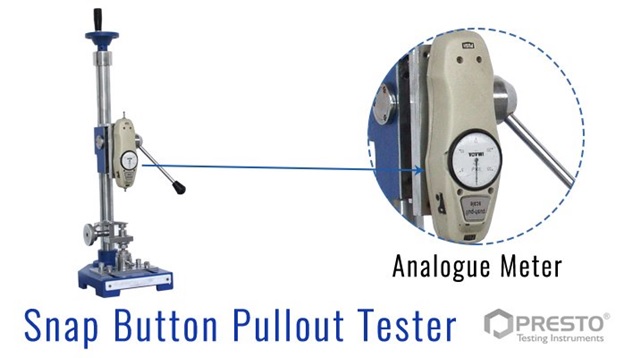

Take a very common example of buttons. If not tested appropriately, they would easily get detached from the garment and may cause choking hazards. Therefore, as a precaution, depending upon the type of button, testing is done. E.g. for prong ring type buttons, computerised snap button pull out tester is used. Similarly, for different components of garments, different test mechanisms are employed.

Why is Testing crucial aspect for children goods?

As a buyer/ user, I don’t know about the potential risks involved with the goods that I am using for my children, especially for the first time. May be later or after repeated use, I got to know that certain things have certain hazards which I should take care off. So, the ultimate responsibility of the safety lies with the manufacturer or supplier. These products should be designed for safety considering standards and age group of the child. And it has been tested with ample test procedures. Like, a manufacturer cannot recommend a trampoline to be used by a 2 years old child without safety gear and accessories.

Manufacturers need to have a proactive approach when dealing with children apparels and accessories. Assessment of safety requirements should be incorporated during designing and development cycle. A foreseeing approach would help the designer to take apt measures while extreme situations arise.

Techniques to calculate the risk involved and the treatment

To engineer safe to use designs, it is important for the developers and designers to implement a series of safety gateways at every stage of the development lifecycle. It is imperative to identify the potential hazards and treating them at the early stage before starting the mass production. Here, concluded a small list of tests and their benefits:

Colour fastening test – Colour of infant garments are light and fast. As they grow, the choices of colours increase, and so are the risks associated with chemicals used for dyeing. Substandard colours tend to bleed when come in contact with sweat and other liquids. These chemical dyes may create skin hazards for the infants. Spectrophotometers and colour matching devices are used to see the effect of repeated washes on the colour of the garment. If there is a considerable difference with every wash, this means, the fabric will lose the colour very easily if the child is taking the cloth in the mouth or during sweating. In response to this, quality managers take suitable control measures to incorporate good dyeing processes.

Button testing – Garments are usually incomplete without buttons. Users cannot even imagine how dangerous these buttons could be if swallowed. To avoid any potential choking hazards, the tensile strength of buttons is measured using snap button pull out the tester. This is a very simple test to assess the strength required to detach the snap buttons from the garments. Similarly, flat buttons are tested in the same way. These tests may sound unimportant for the manufacturers but pose a critical danger if go unnoticed.

Pilling test – Well, pilling is very common in natural fabrics. Due to the unaltered structure of the fabric, fabrics like cotton develops pilling. As such, this pilling does not create and crucial health risks. But you cannot predict a child’s behaviour. Due to pilling, there are loose threads and lint accumulates on the fabric. Children have a tendency to put everything in the mouth, they may try to eat these lint balls or this lint can cause rashes on the sensitive skin. Machines like Martindale abrasion tester helps in evaluating such properties of the garment.

This all was about the kids’ garments. Ample of tests are performed on apparels and accessories. Like for shoes, anti-slip tests are performed. For accessories, there are beads and jewels attached which can be developed risky edges when broken. If manufacturers go by testing standards issued by the regulatory authorities, there is a very long list of tests. Out of which, some are marked as mandatory for every apparel and accessories manufacturer. This might increase the over all production cost, but in the end, it is assuring the consumer the child safety by offering tried and tested designs.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote