UV Weathering Chambers: Your Shield Against Sun Damage

Vishal Malhotra-Testing Instrument Expert

30-04-2025

Suppose you've just bought gorgeous, eye-catching brightly coloured outdoor furniture. It sits beautifully on your patio. But a year from now, or perhaps even a couple of months, that bright colour has disappeared, the plastic is all brittle, perhaps even cracked. Or think about your car's dashboard – ever noticed how older cars can have cracked or discoloured dashboards?

The Silent Destroyer: Understanding UV Degradation

Sunlight, necessary for life, includes UV radiation, a high-energy ingredient that cleaves the chemical bonds in materials. The process, called photodegradation, appears in different

forms depending on the material:

1. Fading & Discolouration: Dyes and pigments degrade, losing their brightness. Whites become yellow, colours fade.

2. Loss of Gloss: Surfaces grow chalky or misty as the surface layer deteriorates.

3. Brittleness & Crack Formation: Polymers (such as plastics and rubbers) become brittle and lose strength, tending to crack and fail.

4. Decreased Physical Properties: Materials may lose tensile strength, impact resistance, and other important properties.

- UV Weathering Chamber (Our star product!)

- UV Test Chamber

- UV Aging Chamber

- UV Accelerated Weathering Tester

- UV Light Testing Chamber

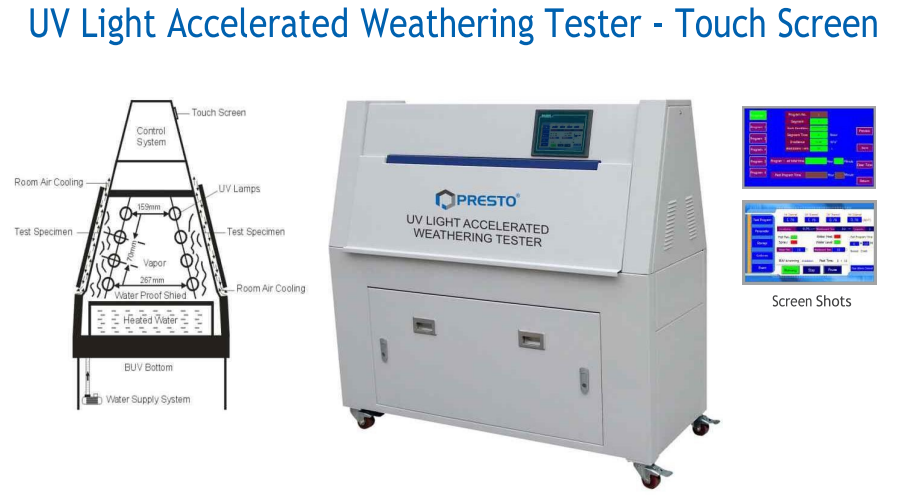

Essentially, all of these are advanced environmental chambers that simulate the conditions causing weathering, but on a massively accelerated schedule. Rather than having to wait months or years for the results of outdoor exposure, a UV Accelerated Weathering Tester can yield worthwhile information in days or weeks.

How Does a UV Accelerated Weathering Tester Work?

The secret to such chambers is that they can control and amplify the most important aspects of weathering:

UV Radiation: Fluorescent UV lamps with specialized technology mimic the essential short-wavelength UV component of the sun (UVA or UVB) that is known to inflict the greatest damage. Intensity is frequently significantly higher than natural light to speed up the degrading process.

Moisture: Actual weathering in the real world is not only about sun, but also about rain, dew, and humidity. The UV Light Testing Chamber replicates this through water sprays (replicating rain) and condensation cycles (replicating dew). Cycles of alternating UV exposure and moisture are usually more harmful than either individually.

Case Study: The Story of the Tough Roofing Tiles

Problem: "Everlast Roofing," a company famous for high-end terracotta-style roofing tiles constructed from a polymer composite, began receiving warranty claims from areas with strong sunlight, such as Arizona and Southern Spain. The customers complained about severe colour loss and chalky appearance occurring within 3-5 years, much less than the claimed 20-year duration. Their image of toughness was at stake.

Solution: Everlast Roofing's research and development department concluded that proactive testing was crucial. They purchased a cutting-edge UV Weathering Chamber, specially engineered for testing materials such as theirs, as a dedicated UV chamber for plastics and composites.

Test Procedure: They exposed their existing tile formulation and some new prototypes (with varying UV stabilizer packages and pigment classes) to an accelerated UV Degradation Test cycle in the UV Test Chamber. The test cycle consisted of alternating cycles of high-intensity UVA lamp exposure, hot temperature, and condensation, which mimics years of tough sun and morning dew exposure accelerated into 2000 hours (about 12 weeks) within the UV Aging Chamber.

Observation: Samples were removed periodically and evaluated for colour change (using a spectrophotometer), gloss retention, and surface integrity (checking for micro-cracking under magnification).

Outcome: The UV Accelerated Weathering Tester was able to speedily identify the vulnerabilities in their initial recipe. Though one sample broke even sooner, two of them were already far more resilient. One specific formulation, containing a synergistic mixture of UV absorbers and HALS (Hindered Amine Light Stabilizers), had very little colour shift and retained top-notch gloss after the complete 2000-hour test.

Having this information, Everlast Roofing went on to reformulate their best-seller with confidence. They were able to now sell their tiles with test-backed evidence of enhanced UV resistance, regaining customer confidence and lowering warranty claims by a considerable amount. Their investment in the UV Light Testing Chamber was well worth it, avoiding further reputation loss and keeping their product up to its "Everlast" name. This showed their Expertise in material science and Authoritativeness in product durability, establishing Trustworthiness with their customers through verified Experience.

The Advantages: Why Choose UV Weathering Testing?

Applying a UV Weathering Chamber provides many benefits:

- Competitive Advantage: Create more long-lasting products than the competition.

- Regulatory Compliance: Comply with industry-specific regulations (e.g., automotive, aerospace, construction) that require weathering resistance.

- Predictive Maintenance: Know how the products will behave during the expected service life in various climates.

Who Requires a UV Test Chamber?

Various industries depend significantly on UV Degradation Testing:

- Plastics and Polymers: Ranging from outdoor furniture (UV chamber for plastics) and playground equipment to automotive parts and packaging.

Paints, Coatings & Inks: Maintaining colour stability and protective properties on metals, plastics, wood, etc. - Consumer Electronics: Testing casings and parts for outdoor or portable equipment.

Frequently Asked Questions (FAQs) About UV Weathering Chamber

Q1. Is it possible to UV Weathering Chamber test both indoor and outdoor products?

Ans: These chambers are primarily established to simulate outside weathering, with a focus on sunlight (UV) and water (rain/dew). These also can be set to simulate indoor light exposure (e.g., fluorescent lighting or filtered window illumination if special light sources are being used) for testing materials such as textiles, inks, or plastics where use is interior but the risk of fading and degradation still is a concern in spite of protective coatings or covering, though base level emphasis and intensity are most often established under outdoor conditions.

Q2. What is the standard practice for UV weathering tests?

Ans: Several international and industry standards regulate UV accelerated weathering tests to ensure consistency and comparability. Some of the popular ones are:

- ASTM: ASTM G154 (for non-metallic materials by means of fluorescent UV lamps), ASTM D4329 (Plastics), ASTM D4587 (Paint & Coatings)

- ISO: ISO 4892-3 (Plastics - Fluorescent UV lamps), ISO 11507 (Coatings - Fluorescent UV and condensation)

- SAE: Standards specific to the automotive industry (e.g., SAE J2020)

Others specific to textiles (AATCC) or specific industries.

Q3. How long does UV weathering testing take?

Ans: This can differ significantly depending on the material being tested, the particular test standard being used, and the desired service life or environment being replicated. Tests can be anywhere from a few hundred to several thousand hours. The trick is acceleration – 1000 hours in a UV Accelerated Weathering Tester may equate to several years of actual outdoor exposure in some climates, but precise correlations need to be made with great care by comparison with actual outdoor testing.

Q4. What industries utilize UV Weathering Chambers?

Ans: As noted above, many industries depend on these chambers. Major users are Automotive, Aerospace, Building Materials (Paints, Coatings, Roofing, Siding, Plastics), Plastics & Polymers, Textiles, Inks & Dyes, Consumer Electronics, and producers of any product to be used significantly outdoors or exposed to light.

Q5. Why is UV weathering testing significant?

Ans: It's vital for numerous reasons:

- Product Reliability: Makes products perform as designed for their anticipated lifespan.

- Safety: Avoids material failures that can create safety risks (e.g., brittle plastic parts cracking).

- Cost Prevention: Prevents failure costs, recalls, warranty claims, and brand damage.

- Quality Control: Assures consistent product quality.

- Research & Development: Provides room for innovation and advancement in material endurance.

- Meeting Standards: Helps meet industry and regulatory standards.

Make Your Product Last Longer

The UV rays of the sun are an ever-present, intense force that can break down even apparently durable materials over time. Disregarding their effect on their products is a risk that makers cannot afford to take. Spending on testing using a good UV Weathering Chamber is not simply a cost; it is a calculated investment in product excellence, reputation, and customer satisfaction. By knowing and anticipating how materials will perform in actual conditions, you can provide products that really last the distance.

Have you had any experiences with UV degradation testing? Have you ever worked with a UV Test Chamber before?

Contact us today or subscribe to our blog for more insights into materials testing!

Looking for the Best UV Weathering Chamber Price?

Get in touch with our experts today to receive a customized quote tailored to your testing needs.

Call Now: +91 9210 903 903

Email: info@prestogroup.com

Don’t miss the chance to invest in reliable quality testing—Contact us now for the best UV Weathering Chamber Price!

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote