5 Uses of Hot Air Oven in Microbiology

Gaurav Malhotra

07-02-2024

A hot air oven is a highly advanced laboratory testing equipment that is specifically engineered for sterilization through the application of dry heat. Stemming from the pioneering research of the esteemed scientist Louis Pasteur, this apparatus holds significant importance in both scientific and medical laboratory settings. Its core objective is to eradicate microbial organisms, including resilient bacterial spores, from a range of heat-tolerant materials. The Presto Laboratory Hot Air Oven stands out as a highly efficient laboratory testing instrument, ideal for evaluating the physical characteristics and lifespan of materials under elevated temperatures.

Operating on the principle of forced air circulation and thermal convection, this oven ensures consistent and precise testing conditions. Its versatility makes it invaluable for conducting a range of essential tests within the rubber and plastic industries. These include assessments for heat deformation, compression set, and heat resistance, providing critical insights into the performance and durability of materials under diverse environmental conditions. Featuring an air-circulating fan, it facilitates consistent and efficient heating. Our hot air oven is equipped with highly standardized specifications, simplifying the process for users to conduct quality tests on materials. In this blog, we will discuss a brief about the uses of hot air ovens in microbiology. But first, we will briefly discuss the working principle of a hot air oven.

What is a Hot Air Oven?

A hot air oven is a laboratory instrument designed for sterilization and material testing using dry heat. It operates by circulating heated air within an insulated chamber, effectively killing microorganisms and drying materials. This device is widely used in microbiology, pharmaceuticals, and industrial applications where controlled high-temperature exposure is required for sterilization and durability testing.

What are Hot Air Oven Uses in a Laboratory?

In laboratories, hot air ovens serve multiple purposes, including sterilizing glassware, metal tools, and heat-resistant plastics. They are also employed for drying chemical samples, curing coatings, and testing material resistance under high temperatures. The precise temperature control and uniform heat distribution make them essential for quality assurance and research applications.

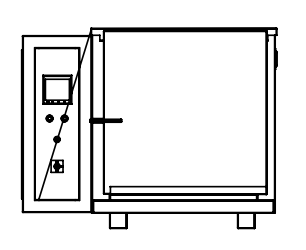

What is a Hot Air Oven Diagram?

A hot air oven diagram illustrates the essential components and working principle of the device. It typically includes parts such as the heating element, thermostat, fan, insulation, and chamber. The diagram helps users understand the airflow mechanism, temperature distribution, and sterilization process. This visual representation is crucial for technicians and scientists to ensure proper usage and maintenance of the equipment.

What is the Difference Between an Autoclave and a Hot Air Oven?

The key difference between an autoclave and a hot air oven is their sterilization method. An autoclave uses steam under pressure (moist heat) at around 121°C to 134°C, making it ideal for sterilizing biological samples and medical instruments. In contrast, a hot air oven employs dry heat at higher temperatures (160°C to 250°C), suitable for sterilizing glassware, powders, and non-corrosive metals that cannot withstand moisture.

What are the Parts of a Hot Air Oven?

A hot air oven consists of several crucial components, including:

- Heating Element: Generates the required temperature.

- Thermostat/Temperature Controller: Regulates heat levels.

- Fan: Ensures uniform air circulation.

- Insulated Chamber: Retains heat efficiently.

- Shelves/Racks: Holds items for sterilization or testing. Understanding these parts helps users maintain and operate the oven effectively for reliable performance.

What is the Temperature Range of a Hot Air Oven?

The temperature range of a hot air oven typically varies between 50°C and 250°C. The most common sterilization temperatures are 160°C for two hours, 170°C for one hour, and 180°C for 30 minutes. Advanced models come with precise temperature control features, ensuring consistent heating for different applications, including material testing and microbiological research.

What are the Uses of a Hot Air Oven in Microbiology?

In microbiology, hot air ovens play a vital role in sterilization and sample preparation. Their common uses include:

- Sterilizing glassware like Petri dishes and pipettes.

- Eliminating microbial contamination from metal tools.

- Preserving bacterial cultures on solid media.

- Assessing heat resistance of microorganisms and bacterial spores.

- Conducting thermal death kinetics studies for microbial control. These functions ensure accurate microbiological testing and contamination-free research environments.

Working Principle of Hot Air Oven

The hot air oven operates on the principle of dry heat sterilization, incorporating conduction, convection, and radiant mechanisms. Manufacturers utilize this method to test their products at elevated temperatures, ensuring effective sterilization of materials.

The inclusion of fans enables efficient circulation of this heated air, ensuring uniform distribution throughout the chamber. Consequently, the sample surfaces are exposed to hot and dry air, facilitating the sterilization process.

This exposure initiates a series of transformative processes. Initially, the external surfaces of the objects undergo heating as a result of direct contact with the hot air. Subsequently, through the mechanism of conduction, this heat is gradually transferred towards the centre of the items, ensuring thorough sterilization.

The high temperatures will induce the evaporation of water present within the microorganisms. This evaporation will lead to a cascade of detrimental effects on different components.

Ultimately, these combined effects culminate in the demise of the targeted microorganisms, thereby achieving sterilization.

Our Presto Laboratory Hot Air Oven offers highly standardized specifications that will ensure seamless usability for conducting a wide array of testing results on various materials.

Uses of Laboratory Hot Air Oven Testing Instrument in the Microbiology Laboratory

Microbiology laboratories will easily make use of hot air ovens for a variety of purposes. Here are five common uses:

- In laboratories, glassware, metal instruments, and reusable plastic containers are frequently sterilized with hot air ovens.

- In microbiology laboratories, waste materials like used Petri dishes, pipettes, and disposable plastic ware can harbour potentially harmful microorganisms.

- Microbial cultures stored on agar slants, agar plates, or other solid media need to be preserved for future use.

- In order to assess the heat resistance of microorganisms, microbiologists may utilize hot air ovens. These specialized ovens are particularly useful for evaluating bacterial spores.

- Scientists can collect valuable data on the thermal death kinetics of different strains and species by subjecting microbial samples to specific temperatures for defined durations. This information is crucial for understanding the efficacy of heat-based sterilization methods and for developing strategies to manage microorganisms in various environments.

You can read more on the use of hot air ovens in the microbiology industry. Ensuring the precise sterilization and temperature control of specific samples is crucial for maintaining product accuracy.

The Presto laboratory hot air oven facilitates the detection of alterations in material properties and determines their durability under elevated temperatures. By utilizing forced air circulation through thermal convection, this system is ideal for conducting essential tests within the rubber and plastic industries. These tests include assessing heat deformation, compression set, and heat resistance, ensuring reliable evaluations of material performance.

Now, let us focus on how you can easily maintain a Presto hot air oven.

How You can Easily Maintain a Presto Hot Air Oven?

This laboratory hot air oven is designed to sterilize your products and ensure the delivery of high-quality goods. If you've invested in this lab testing equipment from Presto, it's important to maintain it properly with the following tips:

- Avoid exceeding the maximum heating capacity and operation timer.

- Clean the machine thoroughly before and after each test procedure.

- Ensure that the chamber doors are securely closed when starting the test.

- Never introduce liquid materials into the heating chamber.

- Provide at least one-foot clearance from the walls when positioning the instrument.

- Confirm that the blower fan is operational during use.

By following these useful and appropriate tips, you can easily maintain a Presto hot air oven. You can read more on how you can easily maintain a laboratory hot air oven efficiently.

Test Your Specimen at High Temperatures with a Presto Hot-air Oven

This dependable and user-friendly testing instrument comes equipped with a sophisticated array of features. It includes a PID controller, renowned for its precise temperature control within the chamber. The built-in timer allows for flexible testing durations, adjustable up to 999 hours. Additionally, numerous other features enhance the utility and effectiveness of this testing equipment. This unit boasts a high heating capacity, capable of reaching temperatures from ambient to 250 degrees Celsius. It ensures uniform heat distribution throughout the chamber, facilitated by advanced PID control. The PID controller is further enhanced with an auto-tuning function for optimal temperature regulation.

The inner body is constructed of stainless steel, providing excellent corrosion resistance for long-lasting durability. Presto Stantest Pvt. Ltd. provides this lab hot air oven at the best and most accurate prices. You can even sterilize different samples with the help of this quality testing equipment. This lab testing instrument operates continuously for extended periods, generating extremely high temperatures. These temperatures are instrumental in effectively eliminating microorganisms and bacterial spores present in the specimen. If you want to know about laboratory hot air oven prices or any other features then you can give us a call at +919210903903 or email us at info@prestogroup.com. Our team of technical experts will consult you for all your needs and queries.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote