Testing Instruments for Metal Testing

Use of Metals in Different Industries

Metals are used, nowadays, on a very large scale as per the current Industrial scenario. Metal products are used for various purposes such as aerospace, industrial machinery, aircraft, construction and many more due to the outstanding properties such as tensile strength, compressive strength, malleability, scratch hardness strength, ductility and many more. The metals are used in different applications where there is a huge demand for high-strength materials.

.jpg)

The metals are used in different applications where there is a great demand for high-strength materials and hence widely used for various crucial applications, where there is no space for the defect, flaws and poor quality. If the quality of the metals is ignored, it can directly lead to horrible situations, fatal accidents and many more. The manufacturers of metal products clearly understand the quality of the materials and must try their level best to produce best quality products. This is possible only by making use of high-quality testing instruments because defects from the metal products can’t be ignored.

Testing Instruments Used in Metal Industries

There is a huge list of testing machines that are used to ensure the quality of the metal products and used in metal industries. These testing machines help the manufacturers of metal industries to test the metals thoroughly so that best quality of materials and products can be delivered to the customers. The widely used testing machine in Metal Industries for assuring the quality of the metals is Salt Spray Chamber. When we think about the quality of metals, the very first thing that clicks in our mind are the corrosion resistance property of metals. Salt Spray Chamber is the machine which helps the manufacturers to analyze the effect of corrosive environment on the metals to ascertain the actual working life of the product.

How can the effect of corrosion be studied?

Corrosion is a major problem that severely affects the quality and working of the metals when they exposed off to open environment. It usually occurs when comes in direct contact with different environmental factors such as salt water, rain water, chemicals, ozone environment, oxygen, moisture, humidity and high temperatures. Corrosion usually destroys or corrodes the quality of the products that makes them fragile. Hence, it is important to measure the corrosion resistance strength of metal products to ensure that the metal products can survive easily in the highly corrosive environment as well.

The salt fog cabinet is an ideal lab testing machine that helps the manufacturers to measure the rust resistance property of the materials. The testing instrument creates best environmental conditions inside the chamber to determine the effect of such conditions on the properties of metals and related products. It is a highly valuable test device which is used by the manufacturers in metal industries to measure the properties of metal products.

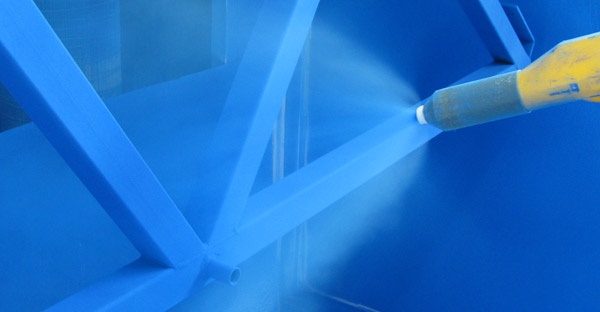

Testing of Coatings on Metals

Coating of the paints, coatings and plating is the most reliable source that protects the metals from corrosion. Hence, it is necessary to coat or plate the product with high-quality of coating sand paints so that the long working life of the product can be ensured and it is necessary to detect the rust proof ability of the paints and metals to choose corrosion proof materials highly. The rust proof ability of the coatings on the metal substrates can be tested using Salt Spray Chamber. The manufacturers of SSC offers different models with sophisticated and latest technology based features and customized specifications to fulfil the testing requirement of large number of people at a time.

The testing machine is designed and assembled by the manufacturers of testing machines to locate the resistance properties of the coating in different environmental conditions. To test the same, the sample is subjected to a salty environment for a set period of time say 24 hours or 48 hours or as per the set conditions. During the test, the test sample is subjected to wet working conditions and salty environment.

How Corrosion test helps the manufacturers?

Corrosion makes the products weaker and causes immediate damage and affects the working life of the product. Hence, Corrosion testing is a significant procedure that must be performed by the manufacturers for continuous production of metal and paint products. The test procedure helps to predict the actual time of the metal at which the corrosion start occurring on the metal and helps the manufacturers to determine the right quality of coating that should be applied to the material. The testing machine is used in the automotive industries to measure the corrosion resistance properties of the spare parts and automotive.

How to perform the standardised corrosion test?

To perform the test, corrosion cycles and different test conditions can be set with the device using salt water spray, dry or wet procedure, etc. to inspect the durability of the coated products. According to the requirements of corrosion resistance test, corrosion cycles can be set to determine the correlation of metals with the environment. The testing instrument is designed mainly by the metal manufacturers for the painted and plated goods.

The testing procedure helps to detect the type of failure that can be occurred on the surface of the metal goods. It is the best testing machine which is used to measure the service life of the metals.

To know more information about its features, price, and technical specifications, give us a call at +919210903903 or email us at info@prestogroup.com.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote