Test Your Bottles for Safety with the Bottle Burst Tester

Vishal Malhotra-Testing Instrument Expert

28-04-2025

Behind the scenes, preserving the integrity of the simple bottle requires a careful production and quality control process. This is where the Bottle Burst Tester, an integral part of Bottle Testing Equipment, enters the picture. From the common PET bottle burst test to the specific needs of glass bottle burst testing, the technology is fundamental to product safety and brand reputation.

What is a Bottle Burst Tester?

Simply put, a PET bottle burst tester, or sometimes called a Container Integrity Analyzer or a burst strength tester for Bottles, is a testing device specifically made to find the highest inner pressure a bottle will endure before it bursts (shatters). It is a rigorous test tool utilized within a variety of different industries – beverage, drug, chemical, food, and cosmetics – to qualify packaging to withstand the pressures that it may be subjected to in its use.

This is generally done by using controlled pressure, usually water in the case of a Hydrostatic Pressure Tester, to simulate real conditions like carbonation pressure, thermal expansion, or stress during handling and transportation. The aim is to identify the weakest point and the specific pressure limit of failure. Knowing this limit is important to manufacturers.

Why is Burst Strength Testing Non-Negotiable?

Conducting strict Plastic Bottle Burst Test procedures, or quality testing for glass bottle burst tester and other material types, is not merely a check-off exercise; it's about real payoffs:

Safety: Most important. Fragile bottles, particularly those filled with carbonated drinks or flammable contents, can be dangerous in the event of an unexpected burst. Testing guarantees packaging to safety specifications.

Product Integrity & Shelf Life: A bottle unable to hold up under pressure may leak, resulting in product loss, contamination, or loss of carbonation, cutting shelf life and quality nearly in half.

Brand Reputation: Product failure, recalls, and negative customer encounters caused by flawed packaging can deeply hurt a brand's reputation and consumer confidence. Quality that happens regularly, guaranteed through testing, generates trust.

Regulatory Compliance: Numerous industries have established regulations on packaging strength and safety. A Burst Strength Tester for Bottles assists in compliance and prevents possible penalties.

Cost Savings: Detecting weak bottle designs or batches prior to reaching the market avoids costly recalls, warranty claims, and wasted product. It also helps optimize material use without sacrificing strength.

Design Optimization: Burst testing gives useful information for R&D, enabling designers to enhance bottle shapes, material distribution, and closure systems for improved performance and possibly lighter weighting (weight reduction).

Case Study: FizzBoost Drinks Combats In-Transit Failures

Problem: FizzBoost Drinks, a leading regional soda producer, began to receive mounting complaints from distributors regarding leaking and sometimes burst bottles delivered to warehouses, especially on summer shipments. This caused lost product, damaged surrounding merchandise, and strained distributor relationships.

Investigation: FizzBoost's quality assurance group suspected temperature changes in transit were causing internal pressure to rise above the tolerances of some of their PET containers. Their current quality controls did not involve rigorous pressure testing across conditions.

Solution: The firm purchased a cutting-edge Hydrostatic Pressure Tester that is made for PET containers. They developed a new QA standard:

- Plastic Bottle Burst Test and random sampling procedures for each batch of bottles they received from their supplier.

- Testing bottles that have been subjected to simulated temperature cycles which simulate transport conditions.

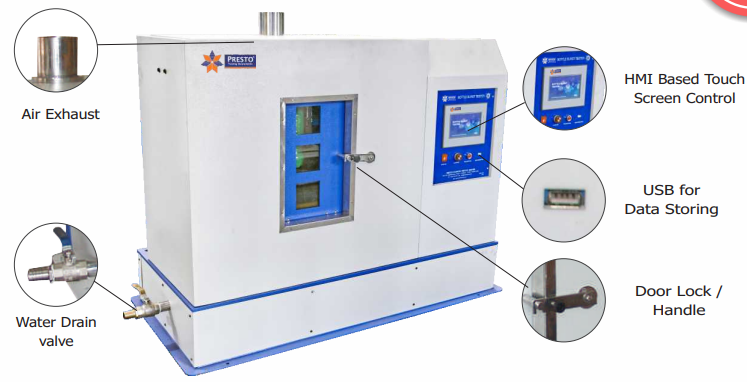

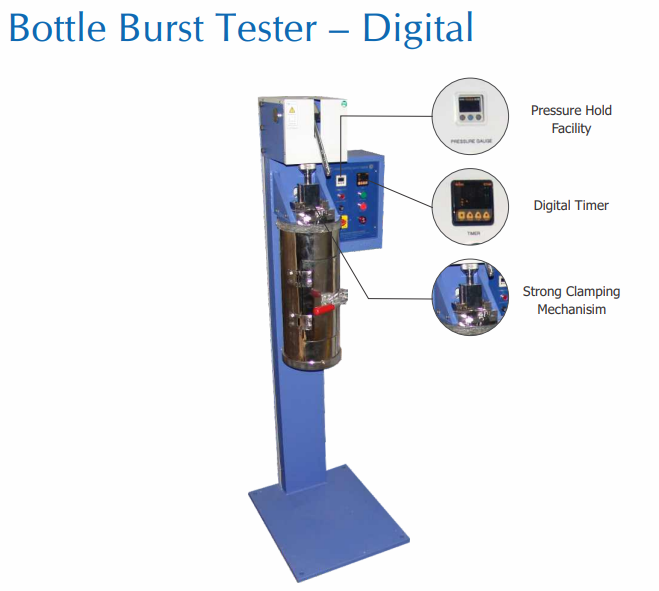

Features That Make Presto Stantest Bottle Burst Tester Stand Out

Presto Stantest's Bottle Burst Tester stands out for its precision, advanced technology, and user-friendly interface, making it ideal for accurate burst strength testing of various bottle materials like glass and plastic. The tester ensures reliable, repeatable results with customizable test parameters, allowing manufacturers to assess packaging durability effectively. Built with high-quality materials, it offers long-term performance and complies with global industry standards. With efficient data reporting and excellent customer support, Presto Stantest ensures that your testing process is smooth, reliable, and aligned with international quality assurance requirements, providing a comprehensive solution for packaging quality control.

FAQs on Bottle Burst Tester

Q1. How do I purchase a good Bottle Burst Tester in India?

Ans. A few good manufacturers and suppliers sell Bottle Burst Testers in India. Seek out well-established companies with good local exposure, favourable customer reviews, and most importantly, strong after-sales support and calibration facilities in India. Think of manufacturers who deal in testing machines for packaging companies, since they usually have models specific to popular bottle shapes (PET, glass) and applicable standards. Look online, visit industry exhibitions (such as Pack Expo India or PlastIndia), and ask for suggestions from industry organizations.

Q2. How often should a Bottle Burst Tester be calibrated?

Ans. Frequency of calibration depends on a variety of factors, including manufacturer recommendations, industry convention (e.g., ISO or ASTM), usage levels, and internal quality control processes. Nonetheless, a typical rule of thumb is at least once a year.

Laboratories of high usage or some industries may want calibration done every six months. If the equipment is moved, subjected to shock, or if in doubt about the readings being accurate, an interim check is highly recommended. Always follow the manufacturer's precise instructions described in the equipment manual. Regular calibration maintains the Trustworthiness and accuracy of your test results.

Q3. How are hydraulic and pneumatic burst testers different from each other?

Ans. The most notable difference is in the medium utilized to produce pressure:

Hydraulic Burst Testers: Employ a liquid, water in most cases (for this reason also referred to as Hydrostatic Pressure Testers). Water is nearly incompressible, so pressure increases gradually and the amount of energy released on a burst is considerably lower and therefore usually safer, particularly at high pressures needed for glass or tough PET bottles. It's the most widely used form for bottle burst testing based on safety and control.

Pneumatic Burst Testers: Operate with a gas, such as compressed air or nitrogen. Gases are compressible, so they contain more potential energy. Though pneumatic systems may sometimes obtain pressure changes quicker, an abrupt burst may be more energetic and potentially unsafe and need very strong safety enclosures. They may be employed for certain leak testing or lower-pressure applications but are less prevalent for high-pressure bottle burst strength determination than hydrostatic methods.

Q4. Is a Bottle Burst Tester suitable for use on bottles of varying sizes?

Ans. Yes, the majority of contemporary Bottle Burst Testers are versatile. They typically come with adjustable clamp systems and holders (necks holds, base supports) that can accommodate bottles of different heights, diameters, and neck finishes. When buying a tester, you must indicate the size range and types of bottles you will be testing so that the model you select and its holders are suitable for your entire product range. Always use the manufacturer's description of the size range of bottles the tester can accommodate.

Get the Best Bottle Burst Tester Price Today!

Looking for a reliable and cost-effective solution to test bottle strength? Contact us now to get the Bottle Burst Tester Price and enhance your packaging quality assurance.

Call Now: +91 9210 903 903

Email: info@prestogroup.com

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote