Secure Seal Tester: Ensuring Airtight Seals for Quality Assurance

.png)

Vishal Malhotra-Testing Instrument Expert

25-03-2025

It is important to maintain the integrity of the seal in the packaging industry, especially for areas that deal with fluids, powder, and delicate objects. Product pollution and leakage, as well as the customer's dissatisfaction and financial losses, can occur from a compromised seal.

.png)

The secure seal tester, an essential tool for quality control, enters the picture here. In addition to answering frequently asked questions, this blog will examine the nuances of secure seal testing, the steps required, and the related tools, such as the SecurePak Torque Tester.

Recognizing the Value of Secure Seals

A safe seal, a leak-proof attachment, or a reliable closed one is crucial for a product's long life and protection. It maintains the product's freshness, keeps contaminants from the packaging, and ensures that the materials are left in the container throughout storage and transport. Reliable sealing systems are crucial for the food and drink, chemical, medicine, and cosmetics industries.

The Secure Seal Test Method:

In order to assess the efficacy of their seals, packaged goods are put through a controlled environment as part of the secure seal test procedure, also known as a closure integrity assessment. The following steps are usually involved in this process:

Sample Preparation: From the production line, choose a representative sample of packaged goods. Make sure the samples are clear and devoid of any outside debris.

Equipment Setup: Get safe sealing exams, sometimes referred to as a leakage detection tool or a closing integrity exam. It can check that the instrument works properly and calibrate it.

Applying Pressure/Vacuum: Either positive pressure or a vacuum is applied after the package has been placed inside the testing chamber. The product type and industry norms determine the precise pressure and time.

Observation and Measurement: The package is examined for indications of leakage, deformation, or seal failure both during and after the application of pressure or vacuum. This could entail pressure decay measurements, bubble emission testing (for submerged samples), or visual inspection.

Data Recording and Analysis: To ascertain whether the seal satisfies the necessary requirements, the test results are recorded and examined. This information is essential for spotting possible problems during the packaging procedure.

Manual for Secure Seal Testers:

An indispensable tool for operators is the secure seal tester manual, also known as a closure integrity testing guide. It offers comprehensive guidelines for configuring, using, and maintaining the testing apparatus. Usually, the handbook contains:

- Features and specifications of the equipment.

- Detailed instructions for carrying out different tests.

- Troubleshooting advice for typical problems.

- Schedules for maintenance and calibration.

- Safety instructions and measures.

Rotational Force Measured by the SecurePak Torque Tester

A SecurePak torque exam is a torque measurement tool to determine the rotational force needed to open or close the container. This is particularly crucial when closing the screw cap because maintaining a tight seal requires a steady torque.

To avoid overtaking, which can damage the seal, and damage submission, resulting in leakage, the torque tester helps determine if the ribbon is used with the right force.

Glass Bottle Secure Seal Tester

Due to the special properties of glass packaging, Safe Seal Examiners require glass bottles, also known as glass container leakage detectors, for specific functions. Drinks, medicines, and other delicate objects where sealing integrity is needed are often packed in glass bottles. The testing procedure could include:

![]()

- Putting the bottles in a water bath to look for air bubbles that might be signs of a leak.

- Putting pressure on the headspace to find the seal's weak spots.

- Non-destructive testing techniques are used to prevent the glass from breaking.

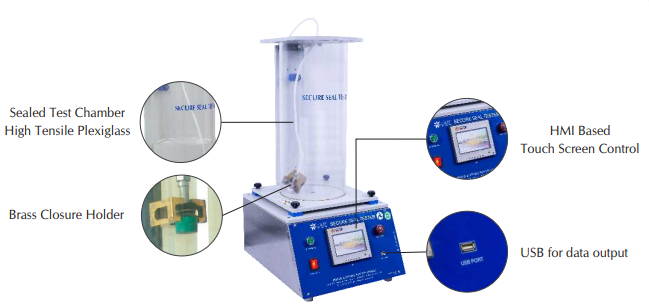

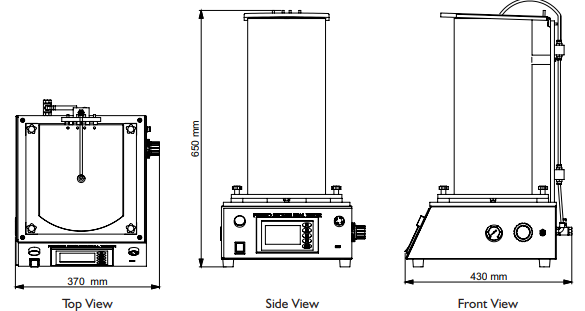

Secure Seal Tester Diagram – Its Working Mechanism

A Secure Seal Tester is a vital instrument used to test the seal integrity of bottles and containers to prevent leakage. The diagram of a Secure Seal Tester illustrates its key components, including the sealing chamber, pressure gauge, and testing controls.

By applying controlled air pressure, it helps manufacturers ensure airtight and leak-proof packaging, maintaining product quality. Understanding its working mechanism through a diagram enhances efficiency in quality control processes.

Secure Seal Tester Price

The price of a safe sealing examiner, another name for the closing integrity test tool, can vary significantly based on several factors:

- Type of Tester: Manual testers are usually less expensive than automated systems.

Features and Capabilities: Advanced testers with automated testing procedures, data logging, and accurate measurement capabilities are more expensive. - Brand and Manufacturer: Manufacturers with a solid reputation and proven track record might charge more.

- Customization: The cost may go up for solutions made to meet industry standards or particular packaging types.

- Maintenance and Calibration: Remember to account for the ongoing maintenance and calibration expenses.

FAQs

What is a secure seal test?

By subjecting a package to regulated pressure or vacuum, a secure seal test, also known as a closure integrity test, evaluates how well a package is sealed and finds leaks or seal flaws.

What is the cost of a secure seal tester?

Safe selection excavators vary widely in expense from a few hundred to several thousand dollars, depending on the manufacturer, kind, and attributes.

What is a seal test?

A sealing test is a common term for any process used to assess the quality and efficiency of the seal of a package. This may include leakage detection, torque dimensions, and other tests.

Why is a secure seal test important?

A secure seal test is crucial for:

- Stop product pollution and leakage.

- Product freshness and maintenance of durability.

- To ensure compliance with industry rules.

- Protect consumer safety and satisfaction.

- Reducing product waste and financial losses.

Which industries use Secure Seal Testers?

Secure seal testers are used in a broad range of industries, including:

- Pharmaceuticals

- Food and beverages

- Chemicals

- Cosmetics

- Medical devices

- Packaging manufacturing

- Laboratories.

Where to Buy a Secure Seal Tester at the Best Price?

Looking for a high-quality Secure Seal Tester at the best price? Presto Group offers advanced testing solutions to enhance your product’s packaging quality. Get the most competitive Secure Seal Tester price with top-notch features and reliable performance.

Call us now: +91 9210 903 903

Email us: info@prestogroup.com

Visit us: www.prestogroup.com

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote