How a Melt Flow Index Tester Helps Ensure Plastic Quality Standards

Vishal Malhotra-Testing Instrument Expert

16-07-2025

In today’s fast moving plastic and polymer industry, keeping up with quality standards is more important than ever. One tool that plays a key role in this process is the Melt Flow Index Tester. It is not just a lab device – it is a must–have for manufacturers wanting to maintain consistency in their products.

This handy machine helps determine how a plastic material will behave when melted and molded. Realization the Melt Flow Index tester working principle can give businesses a competitive edge, especially in industries like packaging, automotive, and medical equipment.

The Melt Flow Index Tester (MFI Tester) is a lab instrument that checks how easily a polymer melts and flows under certain conditions. It measures what’s called the “melt flow rate” — basically how many grams of polymer flows through a capillary die in 10 minutes. This tells you a lot about the material's viscosity and quality.

The Melt Flow Index tester working principle is pretty simple: the plastic is melted in a heated barrel, and then it’s pushed out through a narrow die using a specific weight. The more it flows, the lower the viscosity. This info helps engineers know if the material is suitable for things like film blowing, extrusion, or injection molding

Uses of Melt Flow Index Tester in Industry

The Melt Flow Index Tester is used widely in many industries, and for good reason. Let’s look at a few of them:

1. Packaging Industry

Plastic used for bottles, containers, and films needs to have the right flow rate. If it flows too much or too little, it could affect sealing, durability, and flexibility. The Melt Flow Index testing procedure helps pick the right material grade for the job.

2. Automotive Sector

Car parts like bumpers, panels, and dashboards use high-quality thermoplastics. MFI testing makes sure these materials have the needed strength and heat resistance. Even a small variation in plastic behavior can lead to defects.

3. Medical Devices

Devices like syringes and tubes need to be made from safe, consistent plastic. The Melt Flow Index tester ensures this consistency, which is vital for patient safety.

4. Construction

Pipes, wires, and panels also need plastic with predictable behavior. MFI testers help select the right materials and avoid structural problems later on.

Melt Flow Index Tester Working Principle (Simple Breakdown)

Let’s break this down. Here's how the Melt Flow Index tester working principle plays out:

- You place a sample of polymer in the heated barrel.

- After it's melted to a certain temp (like 190°C for polyethylene), a weight pushes the material through a small die.

- You measure how much comes out in 10 minutes.

- That’s your melt flow index.

The higher the flow, the lower the viscosity — which means the polymer melts easily. Lower flow = higher viscosity.

Melt Flow Index Testing Procedure: Step by Step

Following a Melt Flow Index testing procedure is key to getting accurate results. Here's how it’s generally done:

- Prepare the sample – Weigh and, if needed, dry the polymer granules.

- Heat the barrel – Set the temp based on the polymer type.

- Insert the material – Add granules into the heated chamber.

- Apply weight – Put the piston and weight on the molten material.

- Measure the flow – Collect extruded material and weigh it.

- Clean up – Clean the die and barrel before the next test.

It’s important to stick to the procedure to avoid inconsistent results.

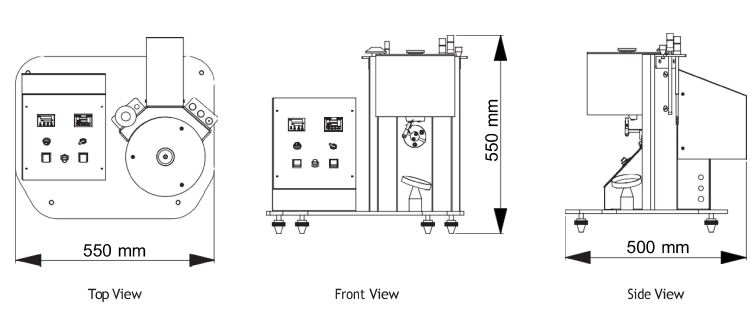

Melt Flow Index Tester Dimensions and Views Diagram

This technical diagram displays the Melt Flow Index Tester in three views—Top, Front, and Side. The equipment measures 550 mm in both width and height, and 500 mm in depth. The top view highlights the control panel and die assembly, while the front and side views show the heater barrel and test outlet. This layout helps in understanding the physical footprint and component positioning, making it easier for setup, operation, and maintenance in lab environments.

Why Use a Melt Flow Index Tester?

Using a Melt Flow Index Tester isn’t just about following a checklist. It offers real benefits:

- Improves quality – Helps ensure plastic behaves the same, every time.

- Saves costs – Reduces waste by helping you choose the right material from the start.

- Ensures safety – Particularly important in sectors like healthcare and automotive.

- Boosts performance – The right material equals better product life and efficiency.

No wonder companies rely on this device for their R&D and quality checks.

A Look at the Melt Flow Index Tester Manual

If you're new to using one, the Melt Flow Index Tester manual is your go-to guide. It usually includes setup instructions, cleaning steps, calibration tips, and safety info. Some features you’ll want to keep an eye out for include:

- Digital display – Shows temperature and test time accurately.

- Automatic sample cutter – Makes the testing more consistent.

- Wide temperature range – Lets you test various plastic types.

- Interchangeable dies and weights – For flexible testing setups.

Pro tip: Always follow the Melt Flow Index Tester manual for cleaning and maintenance to keep your device working well.

Leading Melt Flow Index Tester Manufacturer in India

Presto Group is India’s leading manufacturer of Melt Flow Index Testers, trusted across packaging, automotive, and polymer industries. With advanced features, ASTM/ISO compliance, and reliable after-sales support, Presto ensures precise and consistent testing. Each unit includes a user-friendly manual, making it the top choice for quality assurance professionals.

Bought the product? Call us immediately if you have any questions!

The Last Word on Melt Flow Testing

A Quick Recap: The Melt Flow Index Tester is a silent hero in the world of plastic manufacturing. It may look like a simple machine, but the insights it offers can make or break your production quality.

Realizing the Melt Flow Index tester working principle, following the proper Melt Flow Index testing procedure, and using the Melt Flow Index Tester manual carefully can help you stay ahead of the curve. No matter what industry you're in — packaging, auto, medical, or construction — this tool helps you meet the tough quality expectations of today's market.

So if you're still thinking twice about the Melt Flow Index Tester price, remember — quality is never cheap, but it's always worth it.

Contact us today at +91 9210 903 903 or email us at info@prestogroup.com to learn more about our Melt Flow Index Testers and how they can enhance your plastic quality testing.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote