Environmental Stress Crack Resistance (ESCR) Testing of Plastics

.png)

Gaurav Malhotra

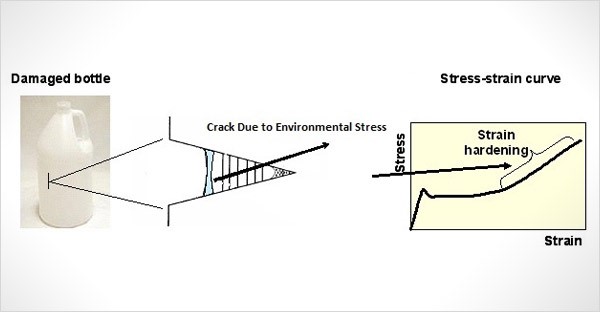

Environmental Stress Crack Resistance (ESCR) is a vital property required in plastics for its longevity. It is one of the most common causes of unexpected brittle failure in thermoplastic. Environmental stress cracking may account for around 15-30% of all plastic component failures in service. Hence, testing of plastics for ESCR is a must for manufacturers.

What is Stress Cracking?

The definition of cracking due to stress is defined in many standards. It is stated as the internal or an external crack in the plastic caused by stresses less than its short-term mechanical potency. This type of cracking usually consists of brittle cracking with no ductile or little drawing of plastic material from the adjoining surface failure. Slow growth in cracks is another term used to explain stress cracking.

The best form of slow crack growth is ESC or Environmental stress cracking. Here are some examples that involve cracking of stresses specimens, usually in the presence of active wet agents like soap, surfactants, alcohol, and others. These wet agents do not attack the polymers directly neither it affects the specimen in any way other than small appearing fractures.

Perform high standard environmental stress crack resistance test, click here for more information.

In the absence of surface active agents, these fractures do not occur in any reasonable period of time under the same conditions. The cracks are usually initiated at tiny imperfections and spread through the nearby regions of the polymer structures. This ability of a plastic specimen or a polymer to resist slow growth in cracks or environmental stress cracking is popularly known as Environmental Stress Cracking Resistance (ESCR). Different Polymers show different degrees of ESCR. Some types of High-Density Polyethylene have good resistance against environmental stress crack while some have minor elasticity.

Why is it important to perform ESCR Testing?

Stress cracking results in failure or breakdown of plastic materials. A plastic required enduring the entire life of a product before it fails. For Polyethylene, this can range from a few months for a juice bottle to several decades for natural gas pipelines and an automobile fuel tank. Hence, before commencing the production, it is quite essential to measure the ESCR and other related properties of a polyethylene for safe and reliable production.

How is Environmental Stress Cracking Resistance measured?

As the quality of the materials has improved over the past few years, the term SCG or Slow Crack Growth is widely introduced in the world of testing to identify the various ESCR methods. To measure the effect the specimens are kept at different temperatures. The higher the set temperature, faster it will produce the cracks. This test procedure is followed to accelerate ESCR testing on the specimen.

Presto Stantest design and manufacture ESCR as per ASTM D 1693 to evaluate the effect of environmental conditions on polyethylene or similar polymers.

If you are looking for Environmental Stress Crack Resistance (ESCR) Price then you can consult with us. We are considered to be the leading Environmental Stress Crack Resistance (ESCR) Manufacturers that will provide you with high quality testing instruments to ensure zero rejections rates from your customers. To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

How it works

Get a Quote