Corrugated Boxes to Determine its Quality

Secondary packaging is an important aspect of the successful delivery of the consignment. Thus, it is very important to create a sustainable packing for different conditions. Whether its cartons or wooden boxes, the packing must be tough to withstand environmental and physical conditions. Corrugated boxes to determine its quality must fulfil required important factors.

In order to get the best quality cartons, its raw material must be good. Also, it should comply with internal standards set as per research and developments. To make the carton strong, it must have sufficient compressive strength, which can be decided as per the intended application. Compression test is usually performed to judge the buckling load of the box.

Perform error-free compression test for best quality packaging. Contact us for more details.

How to Determine the Buckling Load of Boxes

To determine the compression strength or buckling load of corrugated boxes, one of the best options is Compression Test.

Compression test is world widely incorporated into the work process of different manufacturing units. The strength depends on the various factors of the box and they are;

- The structural design of the carton - The shape and dimensions of the box play a major role in deciding the properties of the box. Features like loading direction and flap directions are important considerations.

- Raw material: If the material used has weak strength, the box would collapse immediately after exerting pressure.

- Environmental conditions: If boxes are not tested for intended working conditions, it would lead to the failure of the product. Conditions of the manufacturing unit, warehouse, and final destination matter a lot. Moist air or water prone area directly damage the carton.

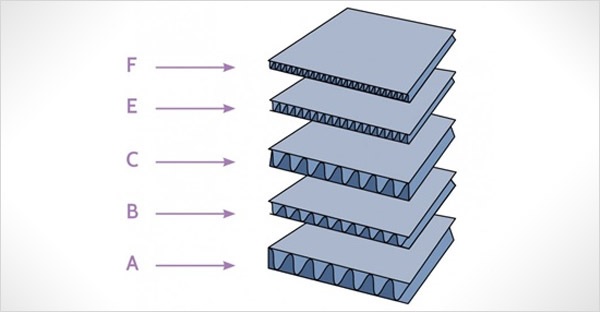

- Corrugated board: If the properties of corrugated boards are poor, the end product will definitely not sustain long.

Selecting the raw material is not a child’s play. A lot of expertise and experience is required to choose the perfect material that can deliver accurate results. To avoid deformation and failure of the boxes, the safety margins are often considered while choosing the raw materials. Due to incomplete knowledge or lack of expertise, sometimes manufacturers ignore this. Thus, awareness regarding the compression test is very important. If the manufacturers don't have the theoretic knowledge, they can at least perform the test and get the values straightway.

Corrugated fiberboard – Important Factor to test

A carton is made up of CFB or corrugated fiberboard. It is made up of corrugators sandwiched in 2 linear boards. The ridges and furrows decide the strength and stress absorbance capacity of the board. If the height of corrugators is more and density is less, its strength will decrease. On the other hand, if the density of the corrugators is more and height is less, the shock absorbance capacity is high. This is an important parameter while choosing the raw material for making cartons.

How to increase the compression strength of corrugated boxes?

Various standards related to packaging have determined the correct box compression strength value for the corrugated boxes with the help of universal standard test method i.e. Box Compression Test. This test can be performed efficiently with the help of a high-quality Box Compression Tester.

The testing machine is used to measure the maximum force which is required to compress the boxes until it ruptures completely. The instrument strictly adheres to various national and international standards like ASTM, ISO, BIS, etc. The effectiveness of box compression testing can also be judged as per TAPPI standards. The instrument is used to perform load compression testing of mono cartons, corrugated boxes, fiber boards, etc.

Get more technical details for Box Compression Tester, reach out to our experts.

The box compression strength of a carton can be calculated by the cardboard’s compression strength and stiffness. The Experimental data and fundamental research depict that, it is quite easy to determine the box compression performance of corrugated boxes with box compression testing. This value is also used to provide grades to different types of boxes. Hence, it is important to measure the compression strength of corrugated boxes to determine its quality in better and accurate manner.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote